Preparation method of industrial combustion gas rare earth addition agent

A rare earth additive, industrial gas technology, applied in the petroleum industry, fuel, gas fuel, etc., can solve the problems of serious environmental pollution, waste of resources, etc., and achieve the effects of improving comprehensive economic benefits, smooth cutting surface, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

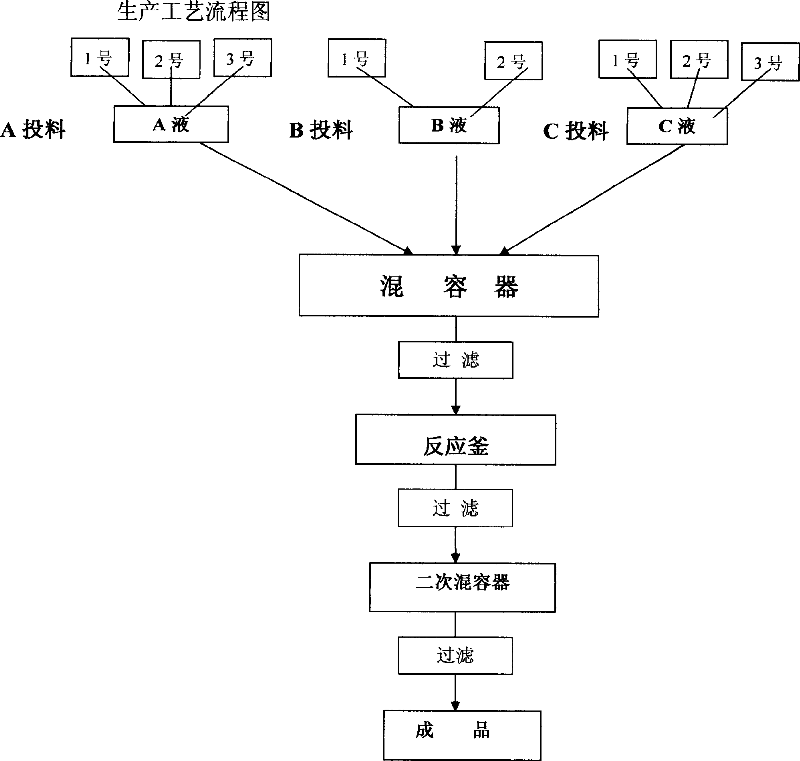

[0014] At normal temperature and pressure, add 20 grams of potassium permanganate to 50 grams of acetone, fully dissolve, then add 30 grams of hydrogen peroxide, and age for 4.5 hours to make A solution; add 20 grams of potassium permanganate to 280 grams of ether Ferrocene, stirred to make it fully dissolved and aged for 4.5 hours to make B solution; mixed with 300 grams of methanol and 200 grams of acetone, added 100 grams of cerium nitrate (rare earth salt) to fully dissolve, and aged for 4.5 hours. into C solution. The three aged solutions of A, B, and C are mixed and then fully stirred, and the industrial gas rare earth additive is obtained after aging for 50 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com