Serialization production method for direct synthesizing alkoxy silane by chlorine-free process

A tetraalkoxysilane and production method technology, applied in the direction of silicon organic compounds, can solve the problems of unsatisfactory production of tetraalkoxysilane, no way to optimize the reaction, expensive copper-containing catalyst, etc., and achieve low cost and high selectivity. and the effect of high space-time conversion rate and low production cost

Inactive Publication Date: 2010-08-11

句容市兴春化工有限公司 +1

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The copper catalyst described in US5084590 directly synthesizes alkoxysilane, however, the main product of this reaction is trialkoxysilane, and the tetraalkoxysilane directly synthesized here is relatively small, and there is no way to optimize the reaction here to avoid Si- Formation of H bonds and production of trialkoxysilanes, in short, the production of tetraalkoxysilanes is not ideal, and copper-containing catalysts require expensive processes, copper catalysts are not suitable for the production of economical and efficient tetraalkoxysilanes

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

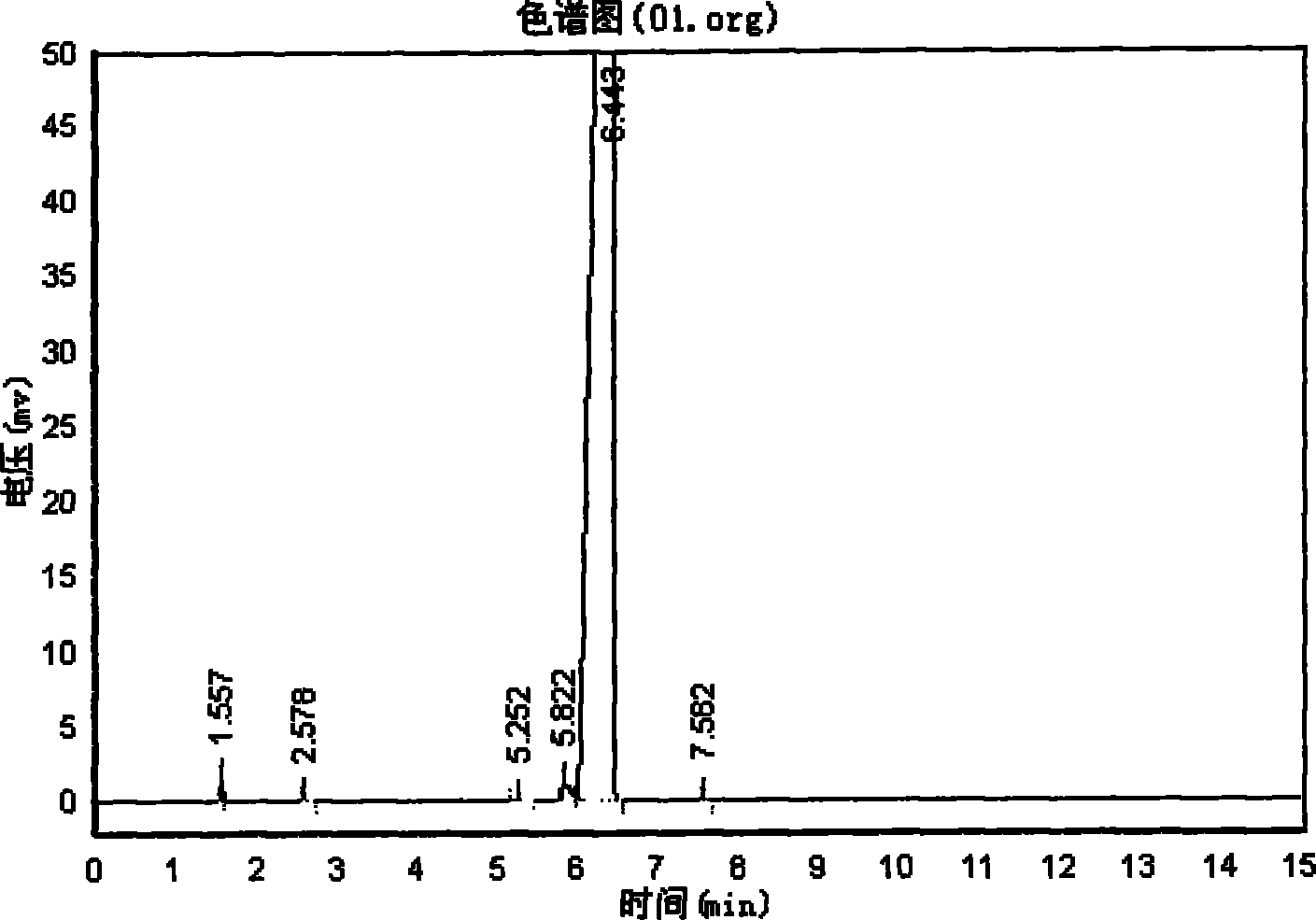

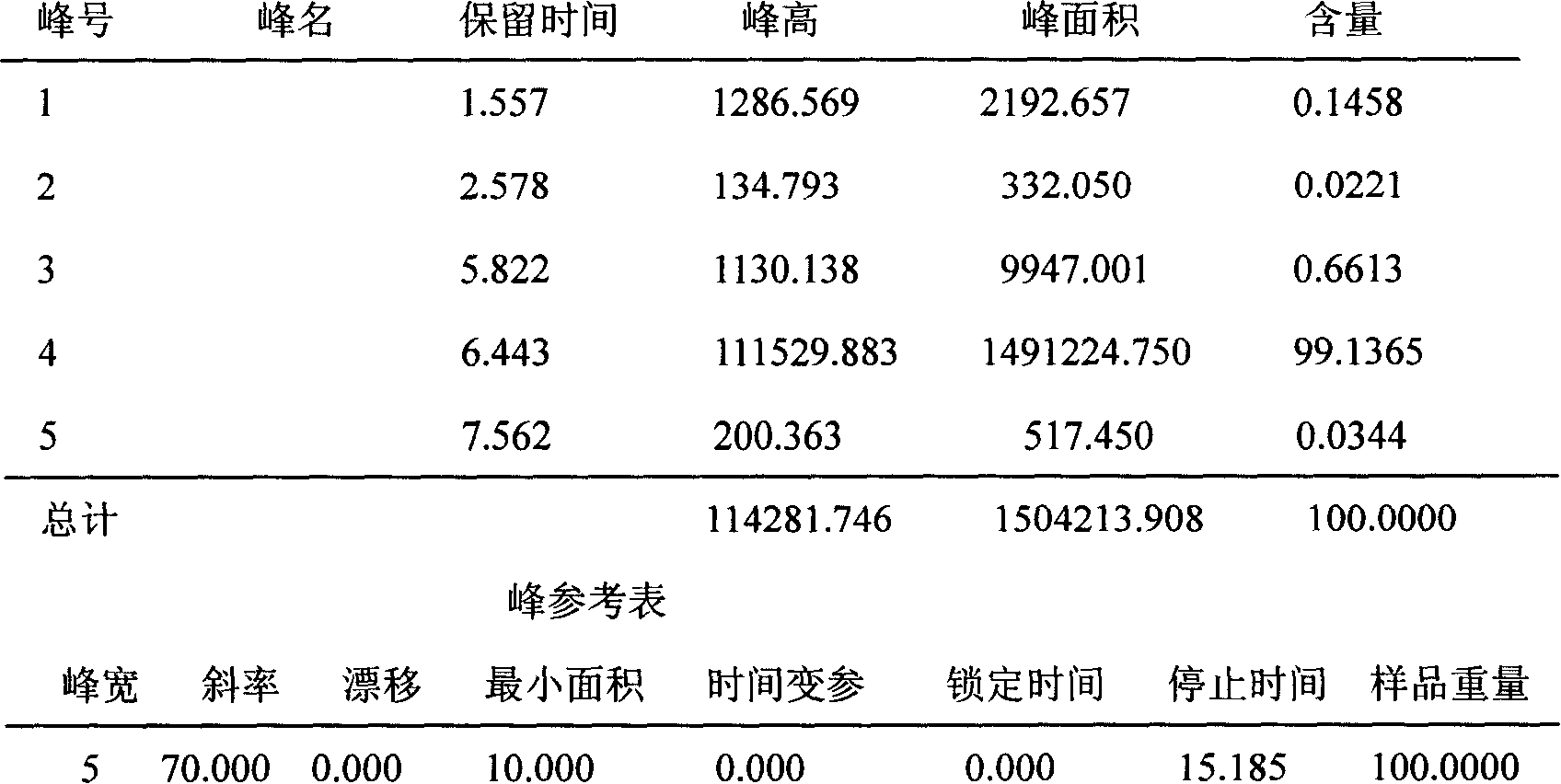

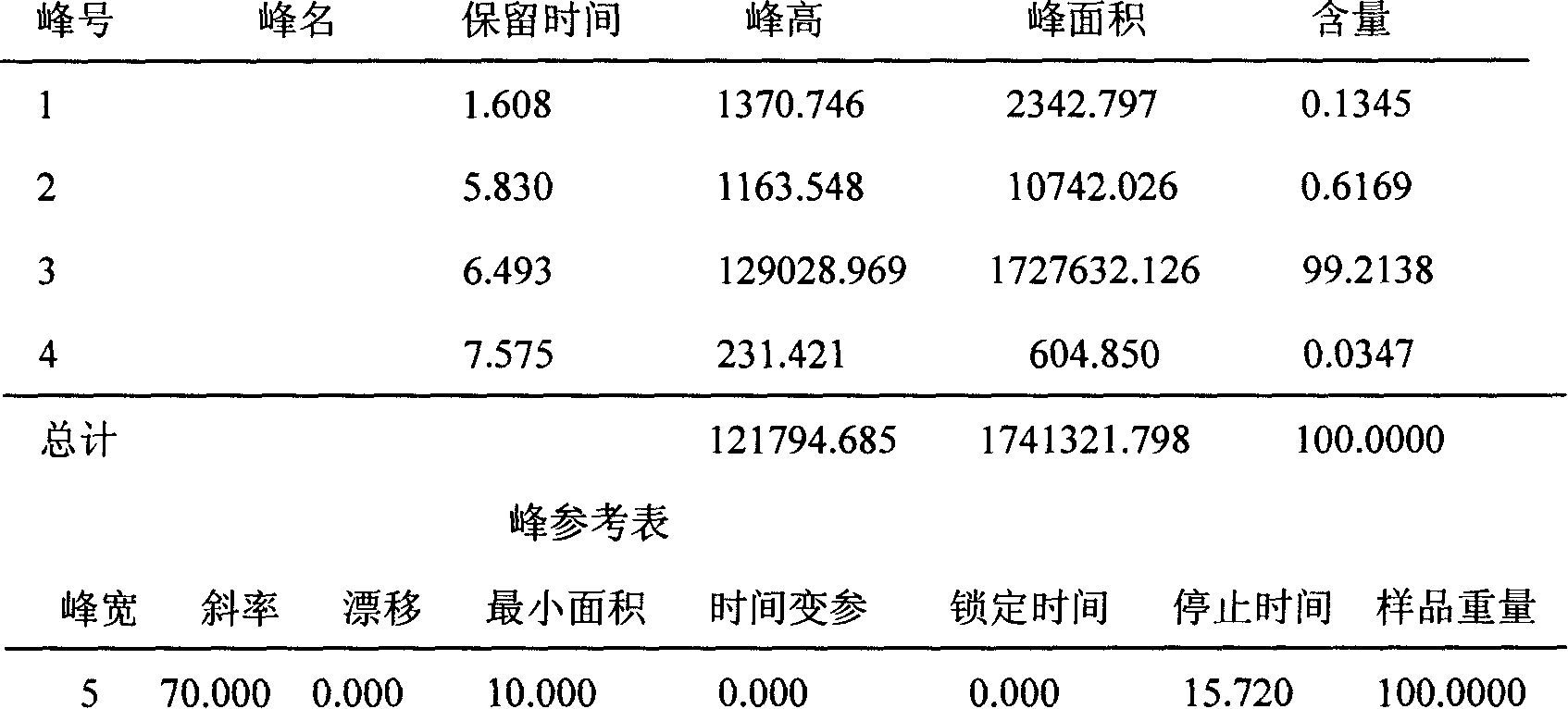

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a continual manufacturing method of tetraalkoxy silicane, which comprises the following steps: blending alkaline catalyst and solvent in the autoclave with weight rate at 1:5-5:1; heating to 130-210 deg.c to activate 2-5h; adding alcohol and 20-80% silicon powder with molar rate at 3:1-1:3 under 150-220 deg.c; transmitting composition into separating tower; draining hydrogen from top of tower; separating tetraalkoxy silicane and low-boiling point component in the separating tower; returning alcohol to autoclave.

Description

technical field The invention relates to a method for continuously producing chlorine-free tetraalkoxysilane, in particular to a continuous production method for directly synthesizing tetraalkoxysilane without chlorine. Background technique Currently known methods for continuous production of tetraalkoxysilane mainly include two types in industry, one is the direct reaction of silicon powder and ethanol, and the other is the esterification reaction of tetrachlorosilane and ethanol. The latter method is that the esterification reaction of tetrachlorosilane can be carried out under normal pressure without adding energy to the simple and easy reactor, and the resulting esterification mixture is distilled to obtain the target product. However, a large amount of hydrogen chloride is produced in the reaction. The corrosion is quite serious, and the environment is polluted at the same time. The tetraalkoxysilane product produced contains chlorine, and the removal of chlorine-contai...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C07F7/04

Inventor 许其民胥成功张征林李林青朱兴华杨亚平

Owner 句容市兴春化工有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com