Diaminobenzenesulfonate polymerization modification polymer materials -PAN Hg ion sorbent and the preparing method

A technology of diaminobenzenesulfonic acid and sodium diaminobenzenesulfonate, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, and can solve the problems of low cost performance, high cost of raw materials, and complex synthesis procedures, etc. problem, to achieve the effect of simple process, low requirements for production equipment and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

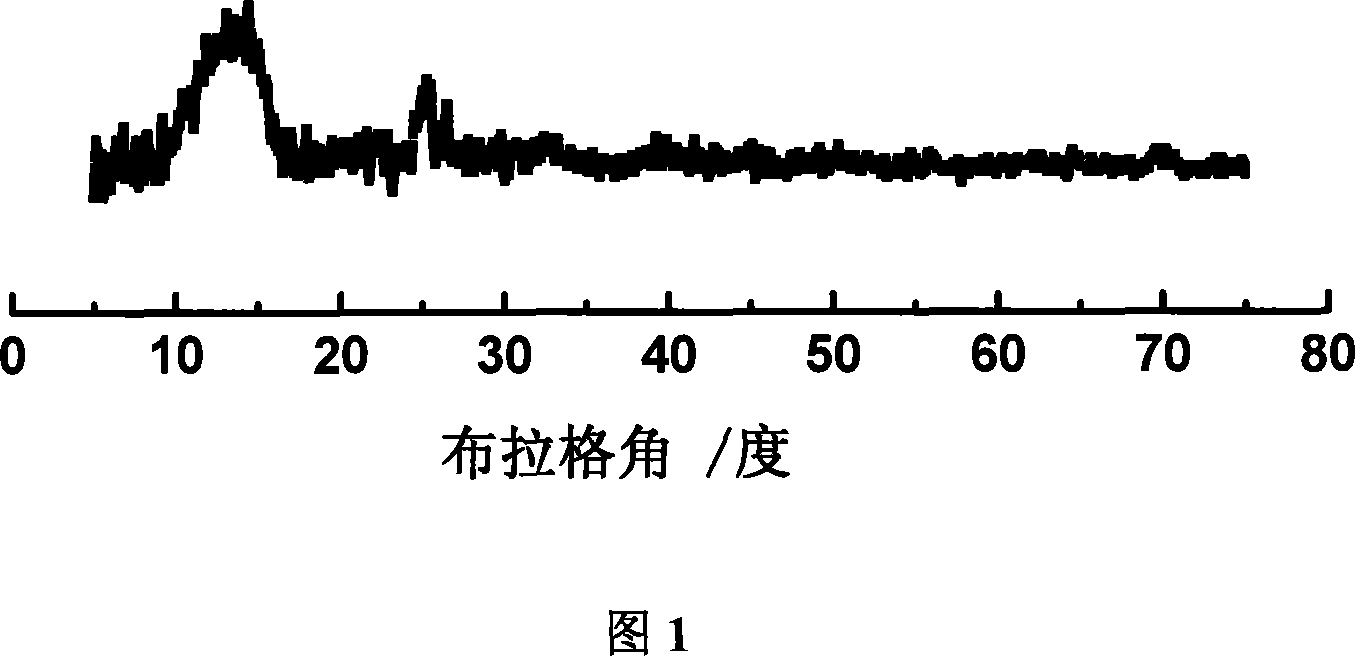

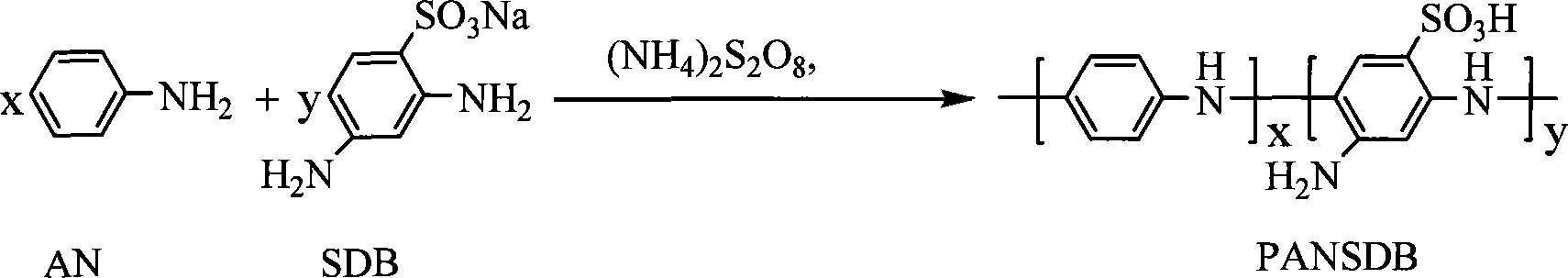

[0033] Embodiment 1~3: prepare AN / SDB copolyaniline

[0034] Accurately take AN monomer 0.054mol (4.92mL, i.e. 5.022g) and SDB monomer 0.006 mol (1.26g) was placed in a 250mL dry and clean beaker, added 150mL 1.0mol / L hydrochloric acid, stirred at 25°C for 0.5h until completely dissolved, and a colorless solution was obtained; the molar ratio of ammonium persulfate / monomer was 1 / 1 , weighed 0.06mol (13.68g) (NH 4 ) 2 S 2 o 8 Dissolve in 50mL of 1.0mol / L hydrochloric acid, stir in a water bath for 0.5h until completely dissolved. Add dropwise (NH 4 ) 2 S 2 o 8 solution into the above monomer mixture. After the dropwise addition, the reaction was continued for 24h. After the reaction was completed, filter and wash several times with distilled water until the 2 Solution test clear solution without SO 4 2- ion until (generally 1000mL of water is used). The product was transferred to a Petri dish and dried at 40° C. for one week to obtain dark green doped PANSDB copol...

Embodiment 4

[0037] Take 50mg of AN / SDB copolymer with a molar ratio of 8:2, put it into 25mL of mercuric nitrate solution with an initial concentration of 5.00mmol / L at 30°C and stir for 24 hours. After filtering with filter paper, titrate the mercury in the filtrate by volumetric analysis. Ion content, the results show that under this condition, the adsorption rate is about 97.4%, and the adsorption capacity is 495.7mg / g.

[0038] Under the same adsorption conditions, the adsorption rate of AN / SDB copolymer with a molar ratio of 7:3 is about 98.3%, and the adsorption capacity is 497.7mg / g.

Embodiment 5

[0040] Take 50 mg of AN / SDB copolymer with a molar ratio of 9:1 and put it into 25 mL of mercuric nitrate solution with an initial concentration of 0.10 mmol / L at 30°C and stir for 24 hours. After filtering with filter paper, analyze the mercury ions in the filtrate with a mercury detector. The results show that the residual mercury ion concentration after adsorption under this condition is 1.75ppb. The adsorption rate is 99.99%, and the adsorption capacity is 9.99mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com