Chip low temperature co-fired ceramic co-mode filter

A low-temperature co-fired ceramic and common-mode filter technology, applied in waveguide-type devices, inductors, fixed inductors, etc., can solve problems such as poor impedance characteristics, failure to filter noise, and inability to effectively reduce differential mode impedance. Achieve the effect of reducing line spacing requirements, low processing difficulty, and reducing electromagnetic leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

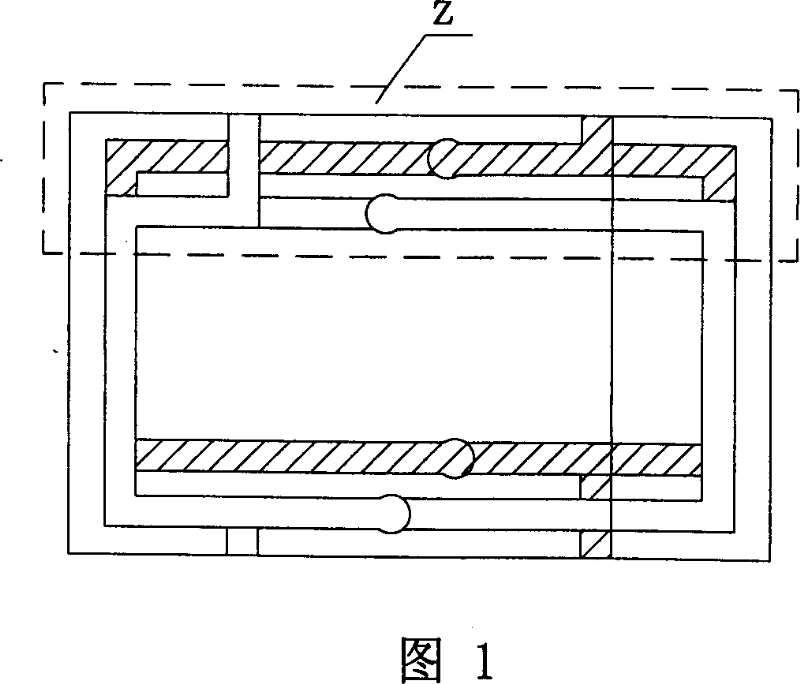

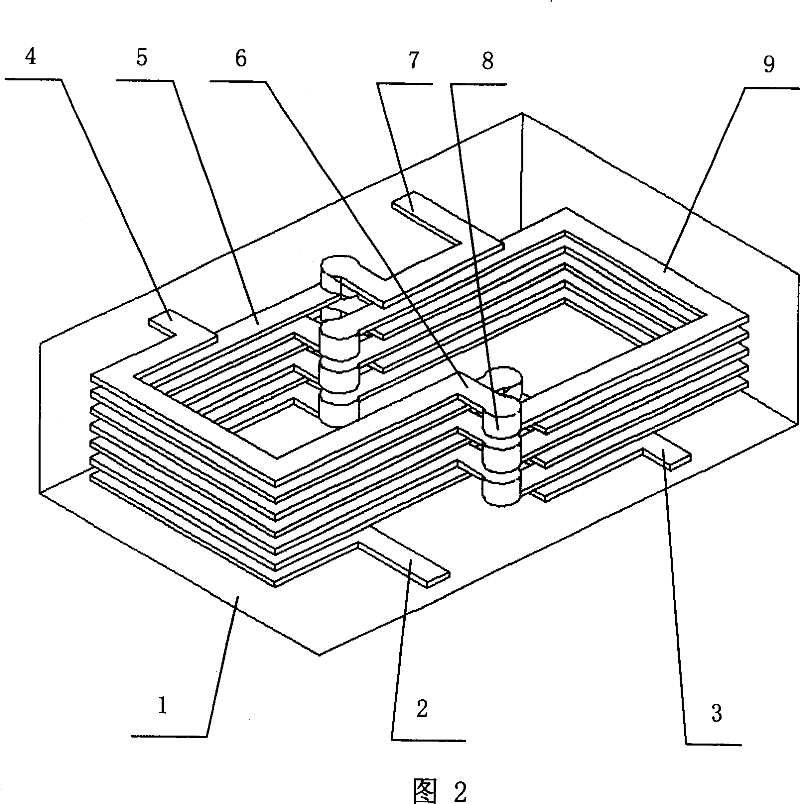

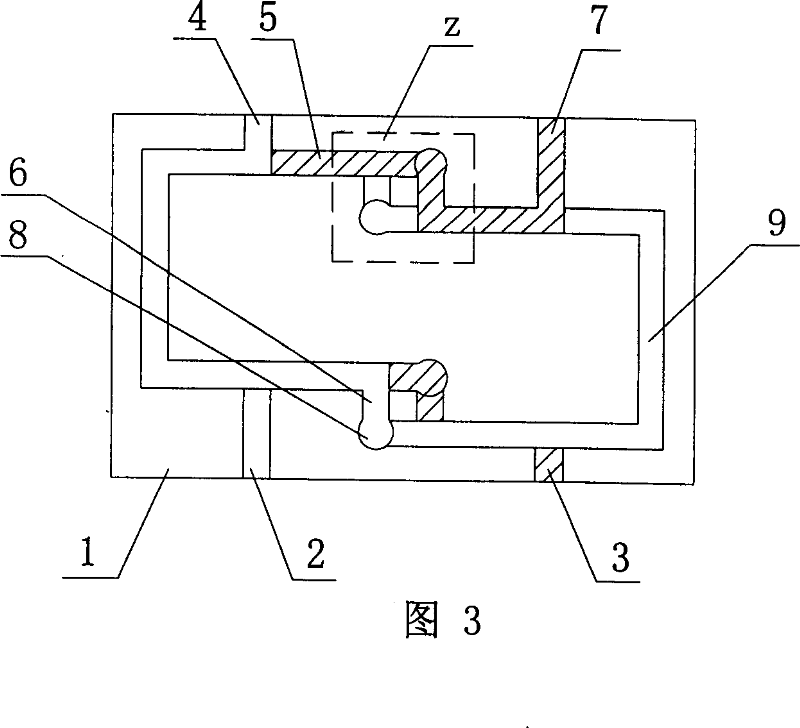

[0029] As shown in Figure 2 and Figure 3, the chip type low temperature co-fired ceramic common mode filter (n is 7 in this example, the printing of each layer is shown in Figure 4-1, Figure 4-2, Figure 4-3, Figure 4 -4, shown in Fig. 4-5, Fig. 4-6), it is made of low-temperature co-fired ceramic body 1 by stacking tape-cast green tapes, and there are 7 layers of left and right layers printed on the low-temperature co-fired ceramic body. Coil and right coil, the 7th layer and the 1st layer are pin layers respectively; one end of the left coil 4 on the 7th layer is connected to one end of the right coil 9 on the 6th layer by a joint 8 (Note: in Figure 2, outside the figure The joint is one end, the joint in the picture is the other end, and the pin is the outer end), the other end of the right coil 9 on the 6th layer is connected with the other end of the left coil on the 5th layer by a joint; the right coil on the 7th layer The other end of 7 is connected with the other end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com