Predicting method for steam turbine high temperature component creep life

A technology of high-temperature components and creep life, which is applied in the field of steam turbines and can solve problems such as different working temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

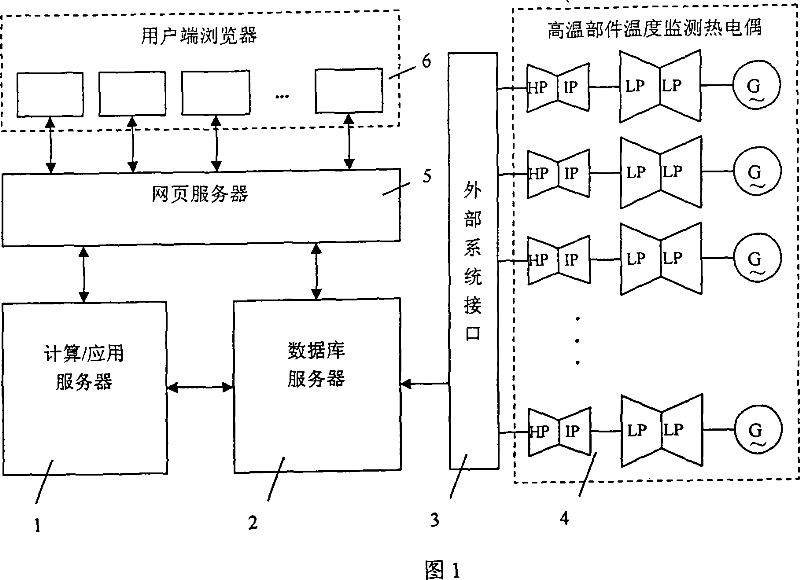

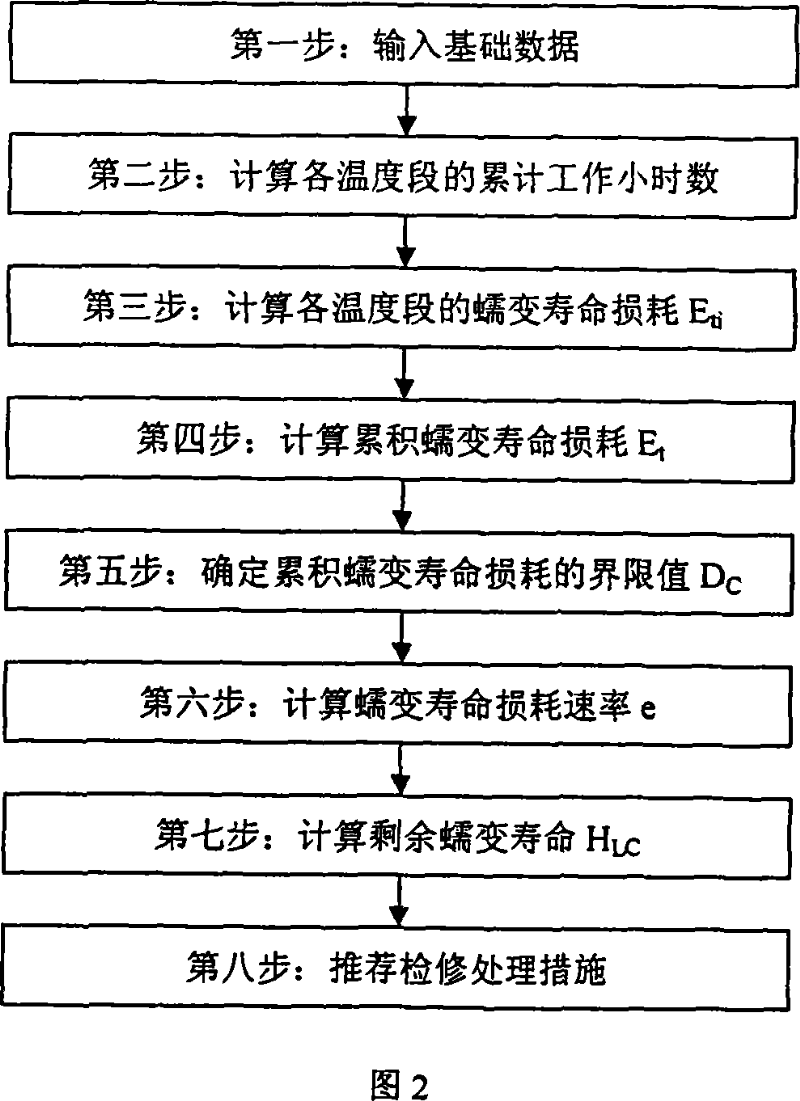

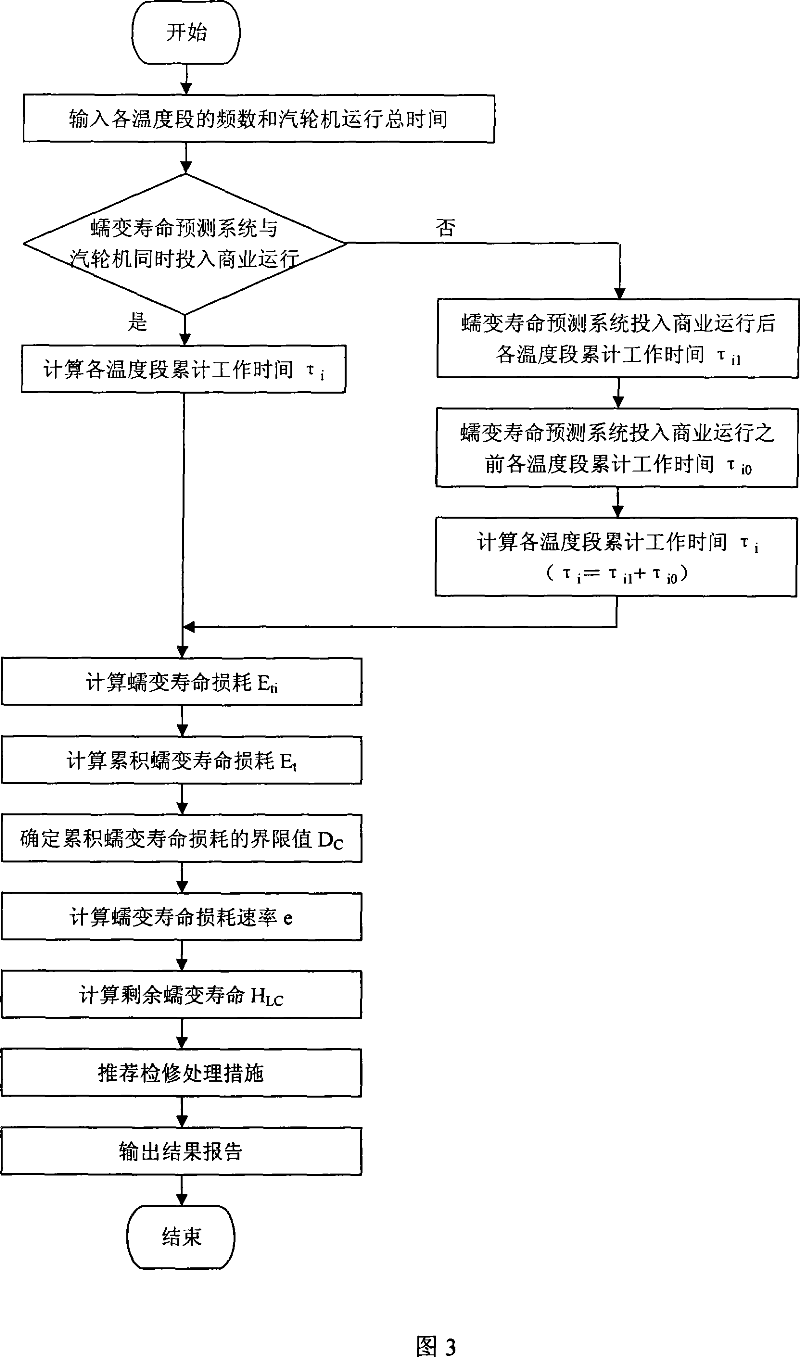

[0064] The main steam temperature of the main steam valve of a certain type of 300MW steam turbine is 538℃ at rated power. The creep life prediction system of high temperature parts of the steam turbine shown in Figure 1 is adopted, and the creep life prediction method of high temperature parts of the steam turbine shown in Figure 2 is adopted. The flow chart and the computer software for predicting the creep life of high-temperature steam turbine components shown in Fig. 3 run on the calculation / application server of the power plant control center. For the valve casing of the main steam valve of this type of steam turbine, the main steam temperature is used as the working temperature of the main steam valve. During the grid-connected operation of the unit, the database saves the main steam temperature data every 3 minutes, and the temperature is above 481℃ (481℃). To 550°C) every 5°C is regarded as a temperature zone, and below 480°C is regarded as a temperature zone. The creep l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com