Preparation method of heavy calcium carbonate and special sharpener

A technology of heavy calcium carbonate and heavy calcium carbonate powder, which is applied in the fields of calcium carbonate/strontium/barium, grain processing, etc., can solve problems affecting environmental cleanliness, waste of raw materials, and increased power consumption, so as to ensure the safety of personnel in operation, Improve the working environment and ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

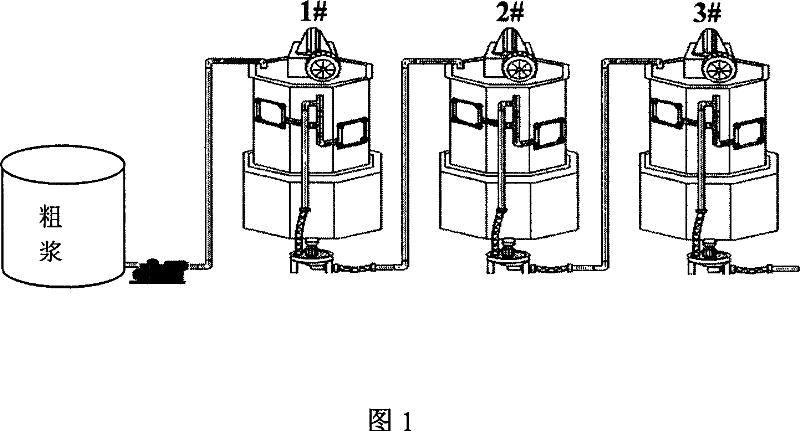

Embodiment 1

[0026] The 325 mesh heavy calcium carbonate dry powder is soaked into a slurry with a solid content of 70-74%, and the slurry is fully stirred to make the slurry have good fluidity. The slurry is pumped to three series wet grinding equipment for three-stage grinding. The unqualified products produced during the grinding process are returned to the first mill for cyclic grinding by the circulation system. When the surface of the equipment heats up to 40°C, the cooling system is turned on to cool down, and after the third mill is tested that the product particle size reaches the standard, the slurry circulation is stopped to stabilize production. The qualified product has a solid content of 76.0% and a particle size of less than 2μm with a content of 95%. The product temperature is 55°C, and the surface temperature of the mill is 28°C, reducing the emission of unqualified products by 5-8 tons.

Embodiment 2

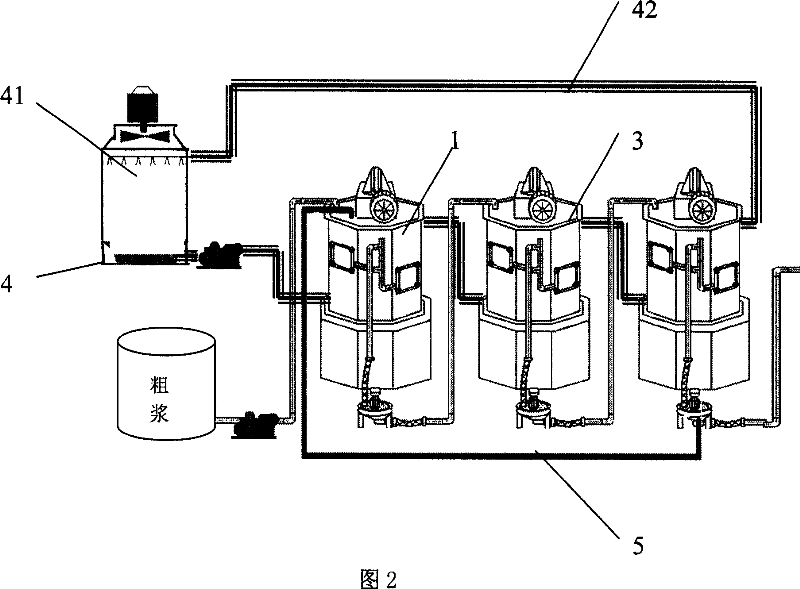

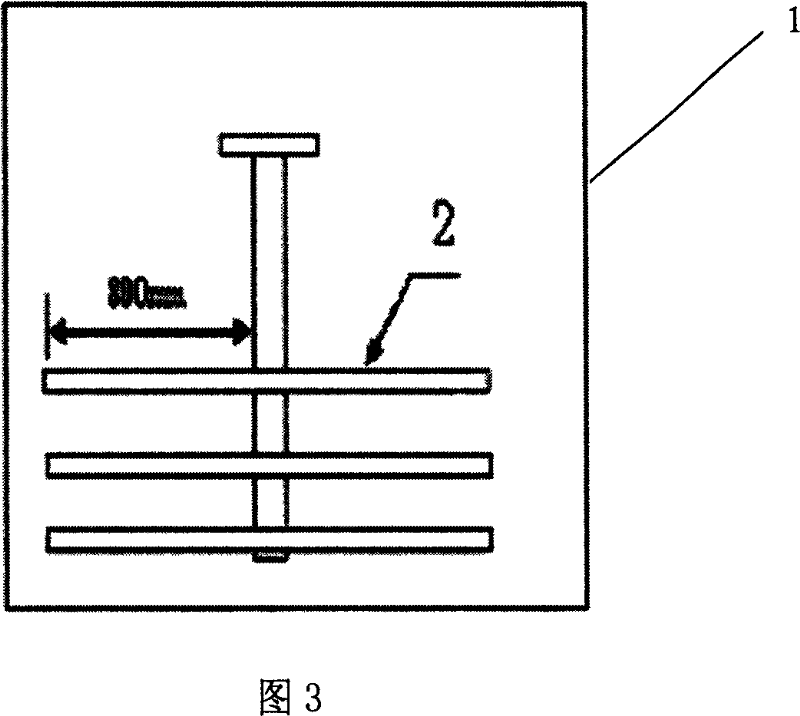

[0028] A special grinding device used in the method for preparing heavy calcium carbonate according to the present invention includes a grinding cavity 1 and a stirrer 2 arranged in the grinding cavity 1. The volume of the grinding chamber is 7.5~8.5m 3 , The volume of the jacket is 0.3~0.5m 3 A jacket 3 for cooling the grinding equipment is provided on the outside of the grinding cavity 1, and the cooling water provided by the cooling system 4 flows through the jacket 3 and then returns to the cooling system 4. The cooling system 4 is equipped with a cooling water tower 41 and a cooling water pipe 42, and the cooling water pipe 42 is connected in series with the grinding equipment. A circulation system 5 is provided at the product outlet of the grinding cavity 1 to return the unqualified products to the grinding cavity 1 for cyclic grinding. The work of the circulatory system is controlled by valves.

[0029] A total of three sets of special wet mills are used, which are applied ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com