MEMS automatic leading interlinking equipment based on zoom microscope location

A technology of wire bonding and microscopy, which is applied in the direction of microscopy, technology for producing decorative surface effects, microstructure technology, etc., can solve the problems of fatigue, time-consuming, unreliable and other problems of the staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

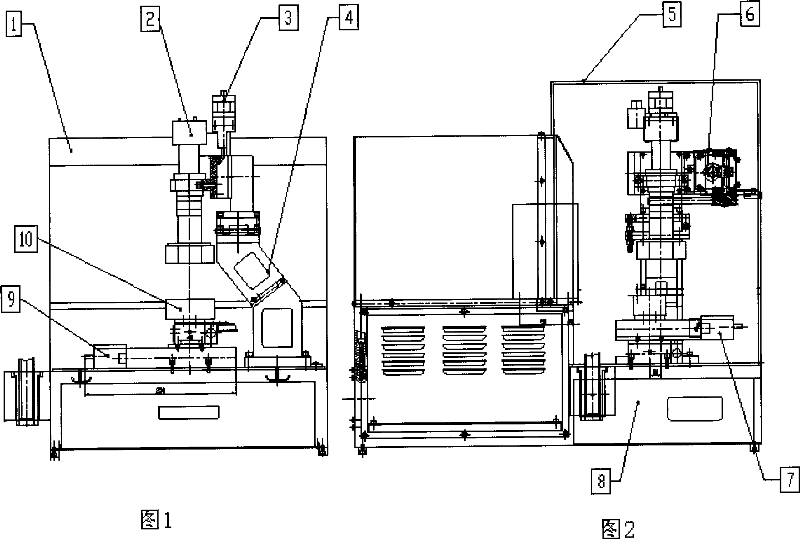

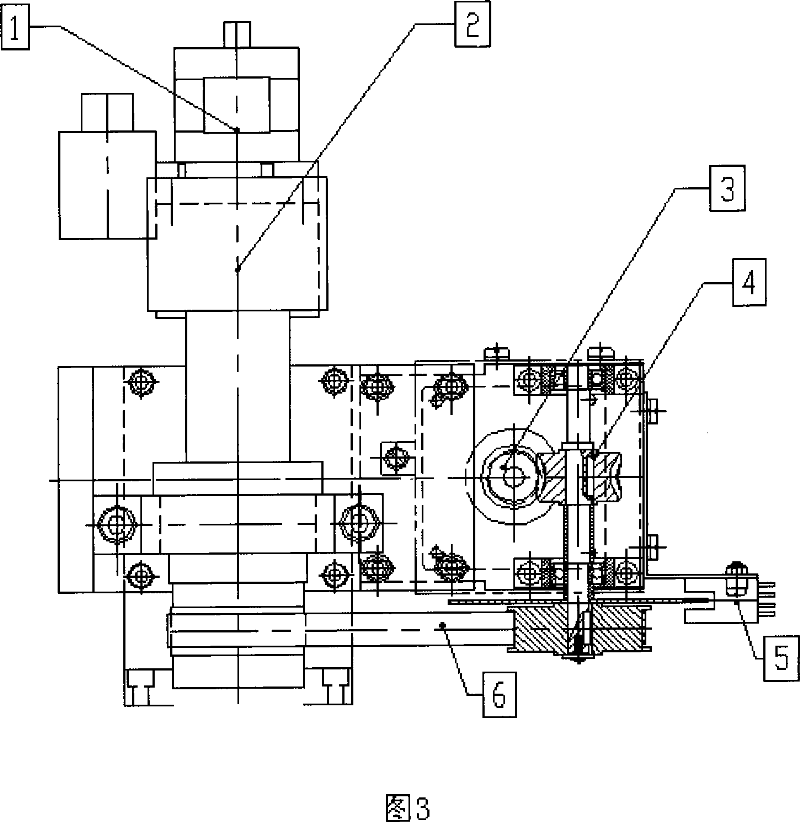

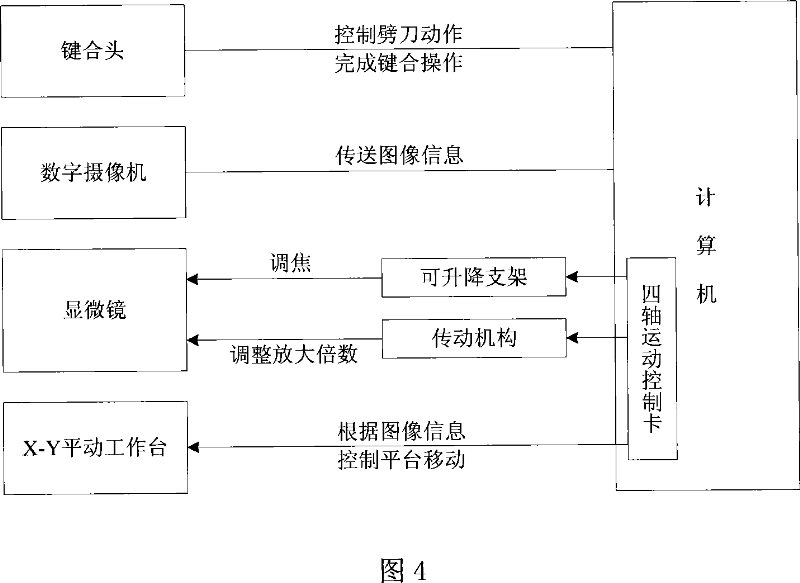

[0023] Combining with Figures 1-2, the composition of the MEMS automatic wire bonding equipment based on zoom microscope positioning includes a base 8, on which an X-axis workbench 9, a Y-axis workbench 7 and a microscope 2 are arranged, above the workbench A bonding head 10 is provided, and a liftable support 4 is provided on the base. The microscope is installed on the liftable support and a Z-axis stepping motor 3 is arranged on the microscope. An automatic magnification adjustment mechanism 6 is installed on the microscope. The face shield has a glass cover 5, and the microscope has a CMOS digital camera. Simultaneously in conjunction with Fig. 3, the magnification automatic adjustment mechanism is driven by a worm gear 13, a worm screw 14 meshed with a worm gear, a pulley 17 mounted on the worm screw, a synchronous belt 16 connected between the pulley and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com