Accumulated-heat correction apparatus and accumulated-heat correction method for thermal head

A technology of a correction device and a correction method, which is applied in the directions of printing and digital output to the printing unit, etc., can solve the problems of color generation, insufficient correction amount, insufficient heat storage correction, etc., and achieve the effect of high-quality printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

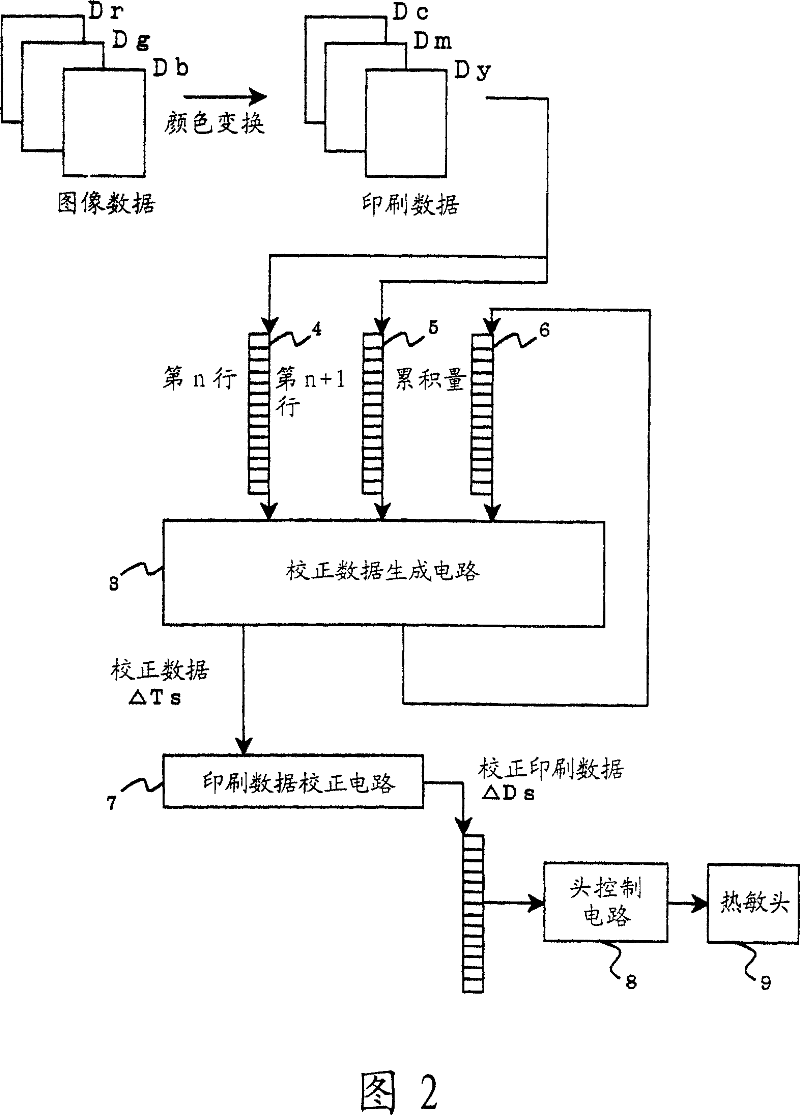

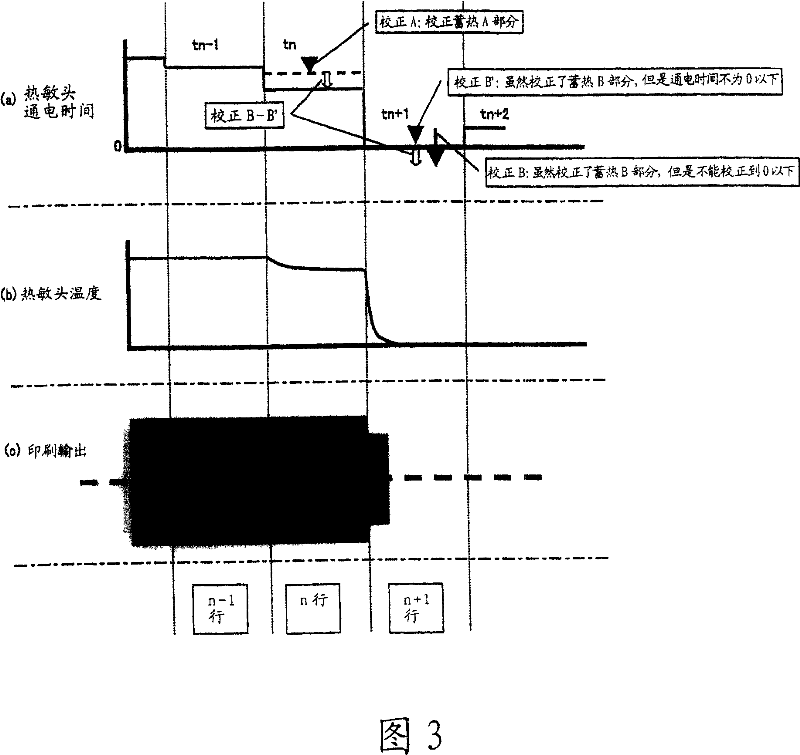

[0033] FIG. 1 is a circuit block diagram showing Embodiment 1 of the present invention. FIG. 2 is a diagram showing a flow of thermal storage correction processing performed by the circuit in the block diagram of FIG. 1 . FIG. 3 is a conceptual diagram showing a thermal storage correction method according to the first embodiment.

[0034] In FIG. 1 , an image memory 1 receives image data Dr, Dg, and Db of RGB colors from an external computer, etc., and a color conversion circuit 2 converts the image data Dr, Dg, and Db of each color into print data Dc, Dm, and Dy of each color. , and store these print data Dc, Dm, Dy in the current storage buffer 4 at the same time.

[0035] And at this point, the accumulated data up to the previous line n−1 is stored in the accumulated memory buffer 6 , and the print data of the next line n+1 is stored in the next memory buffer 5 .

[0036] The correction data generation circuit 3 reads the printing data of the current line n from the curre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com