Method and device of eliminating dust

A technology for a dust removal device and a dust removal chamber, which is applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using gas flow, etc., to achieve the effect of preventing re-attachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

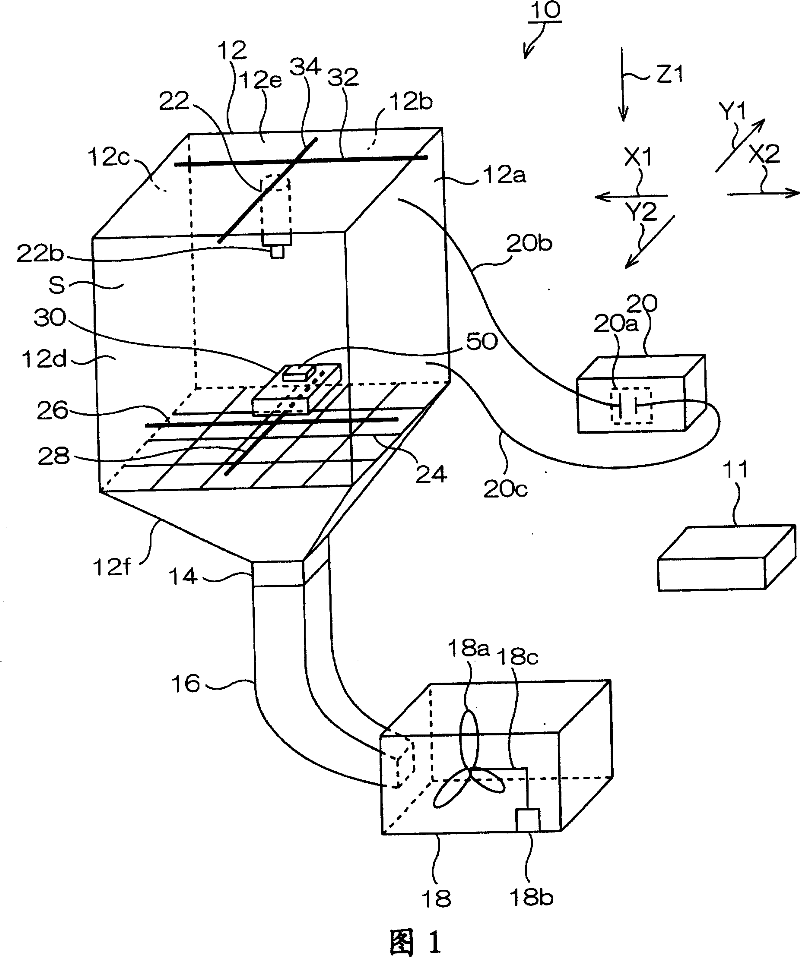

[0037] FIG. 1 is a schematic perspective view showing a dust removal device 10 according to an embodiment of the present invention.

[0038] The dust removal device 10 is an example of a dust removal device.

[0039] As shown in FIG. 1 , the dust removal device 10 has a dust removal chamber 12 . The dust removal room 12 is an example of a dust removal room.

[0040] The dust removal device 10 has a control device 11 for controlling each part. Although the control device 11 is connected to each part, illustration of the connection state is omitted. The control device 11 is an example of a control device.

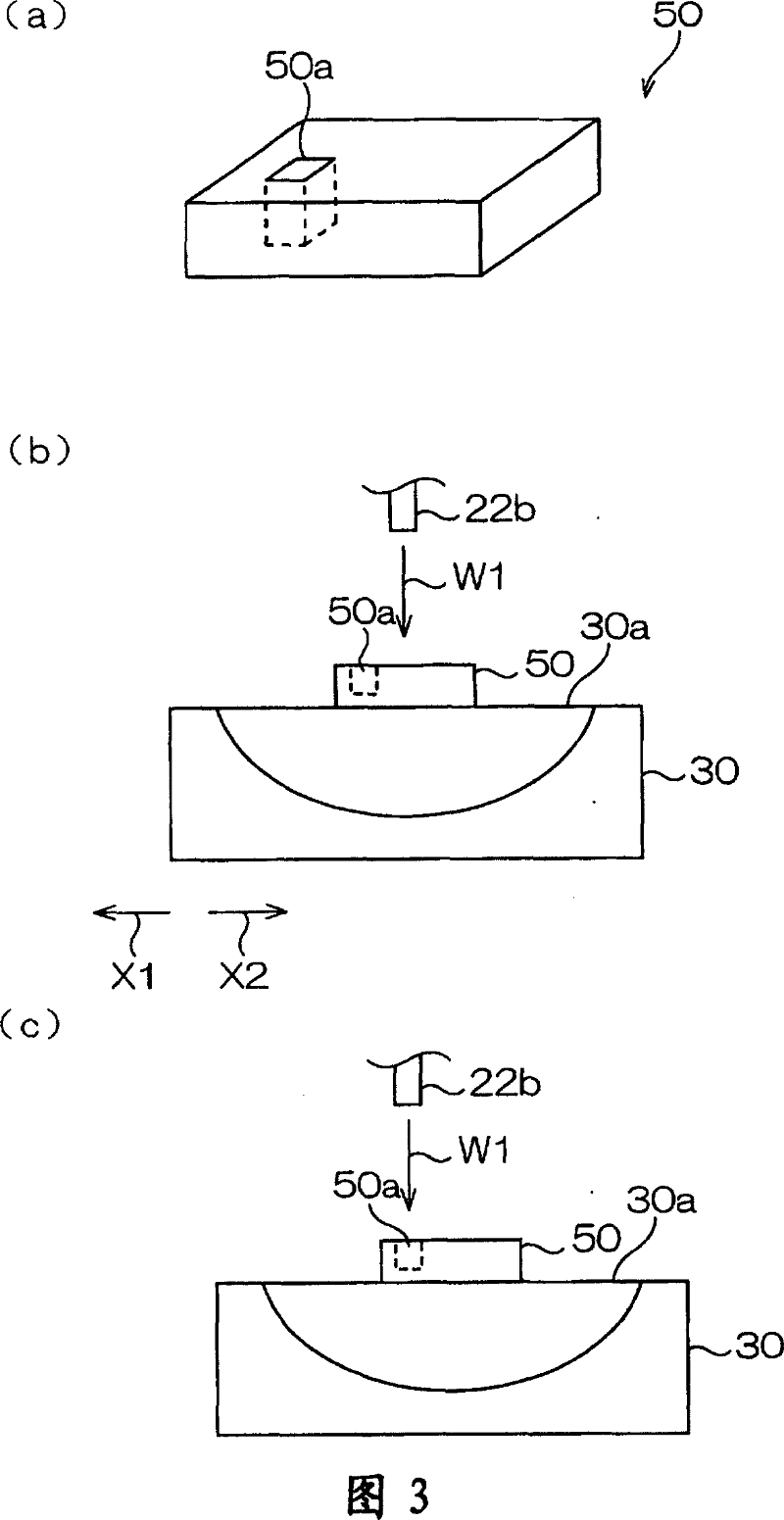

[0041] The dust removal chamber 12 has a holding stand 30 for holding the parts 50 . The holding table 30 is an example of a holding table. Part 50 is an example of a processing target. Part 50 is, for example, a part of a projector which is a precision device.

[0042] The dust removal chamber 12 has side walls 12a, 12b, 12c and 12d. The side walls 12a and the like a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com