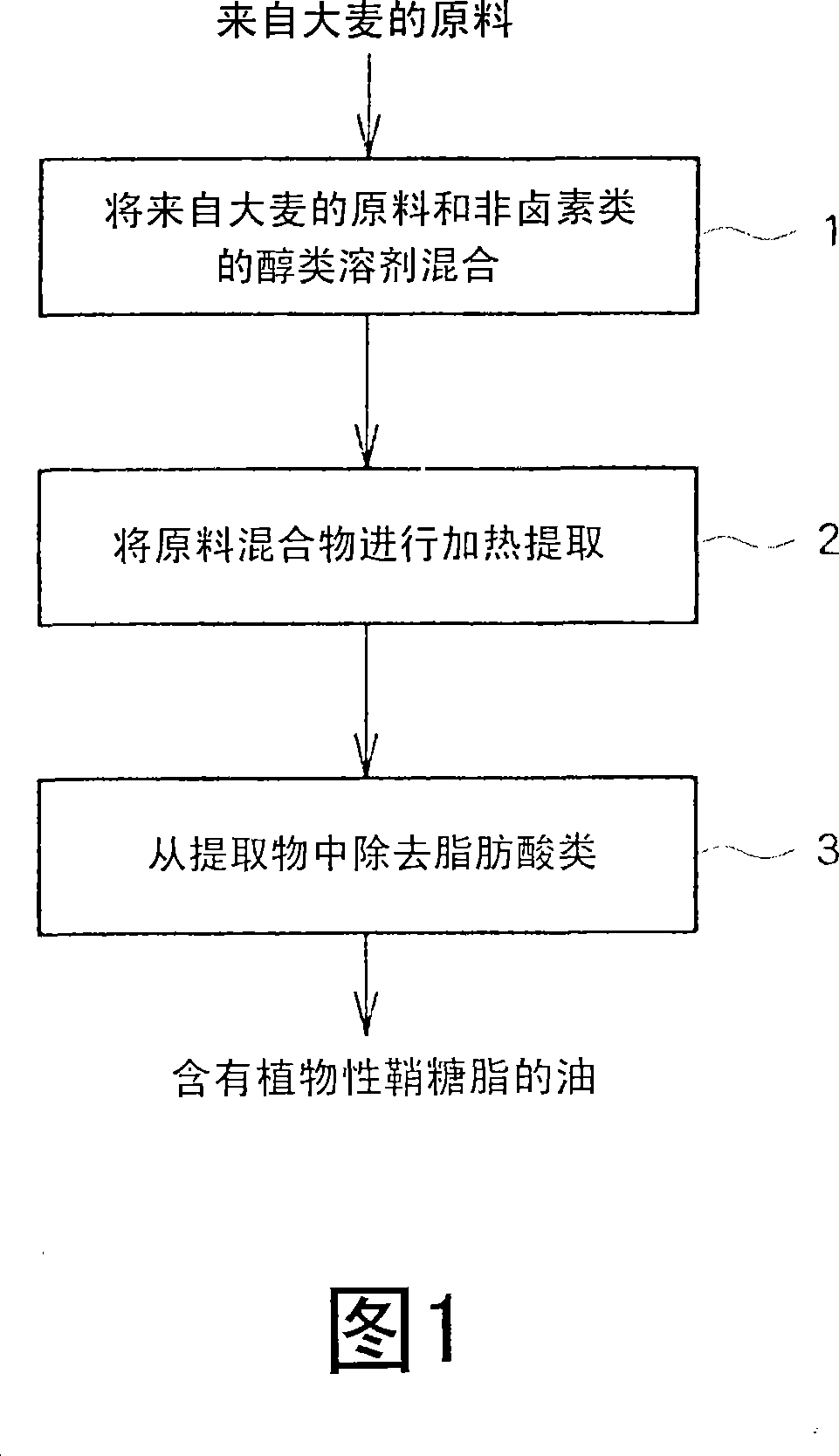

Process for producing oil containing vegetable glycosphingolipid

A manufacturing method and technology of glycosphingolipids, applied in the field of vegetable oil, can solve the problems of unestablished safety and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] As a raw material derived from barley, barley bran containing the barley skin discharged during the whitening process of Hokkaido-grown Ryofu, which is barley for brewing, is used. The heat-extraction treatment accompanied by pressurization was performed by an accelerated solvent extraction (ASE) method. In this high-speed solvent extraction method, a Dionex high-speed solvent extraction apparatus ASE-200 (manufactured by Dionex Corporation) was used as an extraction device. Specifically, 150 g of barley bran containing barley skin is loaded into 10 stainless steel tubes (cell) with a capacity of 22 ml, a solvent mixed with hexane and isopropanol at a volume ratio of 3:2 is added, and placed at a high speed. extraction device. Then, under the conditions that the oven temperature is 125°C, the oven temperature rise time is 6 minutes, the set temperature / pressure rest time is 25 minutes, the flushing volume is 60%, the nitrogen purging time is 60 seconds, and the rest cy...

Embodiment 2

[0040] As a raw material derived from barley, barley bran containing the barley skin discharged during the whitening process of Ryofu produced in Hokkaido, which is barley for brewing, is used. The same Dionex high-speed solvent extraction apparatus ASE-200 (manufactured by Dionex) as in Example 1 above was used. Specifically, 150 g of barley bran containing barley skin was loaded into 10 stainless steel tubes with a capacity of 22 ml, a solvent mixed with hexane and isopropanol at a volume ratio of 3:2 was added, and placed in a high-speed extraction device. Then, under the conditions that the oven temperature is 155°C, the oven temperature rise time is 6 minutes, the set temperature / pressure rest time is 45 minutes, the flushing volume is 60%, the nitrogen purging time is 60 seconds, and the rest cycle is 2 times Heat extraction treatment is carried out. The extract liquid obtained by the heat extraction treatment was collected and concentrated under reduced pressure in an ...

Embodiment 3

[0042] As a barley-derived raw material, barley bran of Ryofu from Hokkaido, which is barley for brewing, was used, and 145 g of the above-mentioned barley bran was put into 10 stainless steel tubes with a capacity of 22 ml, and hexane and isopropanol were added at a volume ratio of 3 : 2 mixed solvent, placed in the Dionex high-speed solvent extraction device ASE-200 (manufactured by Dionex). Then, under the conditions that the oven temperature is 100°C, the oven temperature rise time is 6 minutes, the set temperature / pressure rest time is 15 minutes, the flushing volume is 60%, the nitrogen purging time is 60 seconds, and the rest cycle is 2 times Heat extraction treatment is carried out. The extract liquid obtained by the heat extraction treatment was collected and concentrated under reduced pressure in an evaporator to obtain 24.5 g of viscous vegetal glycosphingolipid-containing barley oil of yellowish brown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com