Low-alcohol high-concentration isomaltose hypgather beer and producing method for the same

A bifidus factor and beer technology, applied in the field of beer brewing, can solve the problems of not prominent flavor, difficult for consumers to accept, low alcohol content, etc., and achieve the effects of prominent hop aroma, enhanced immunity and pure taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

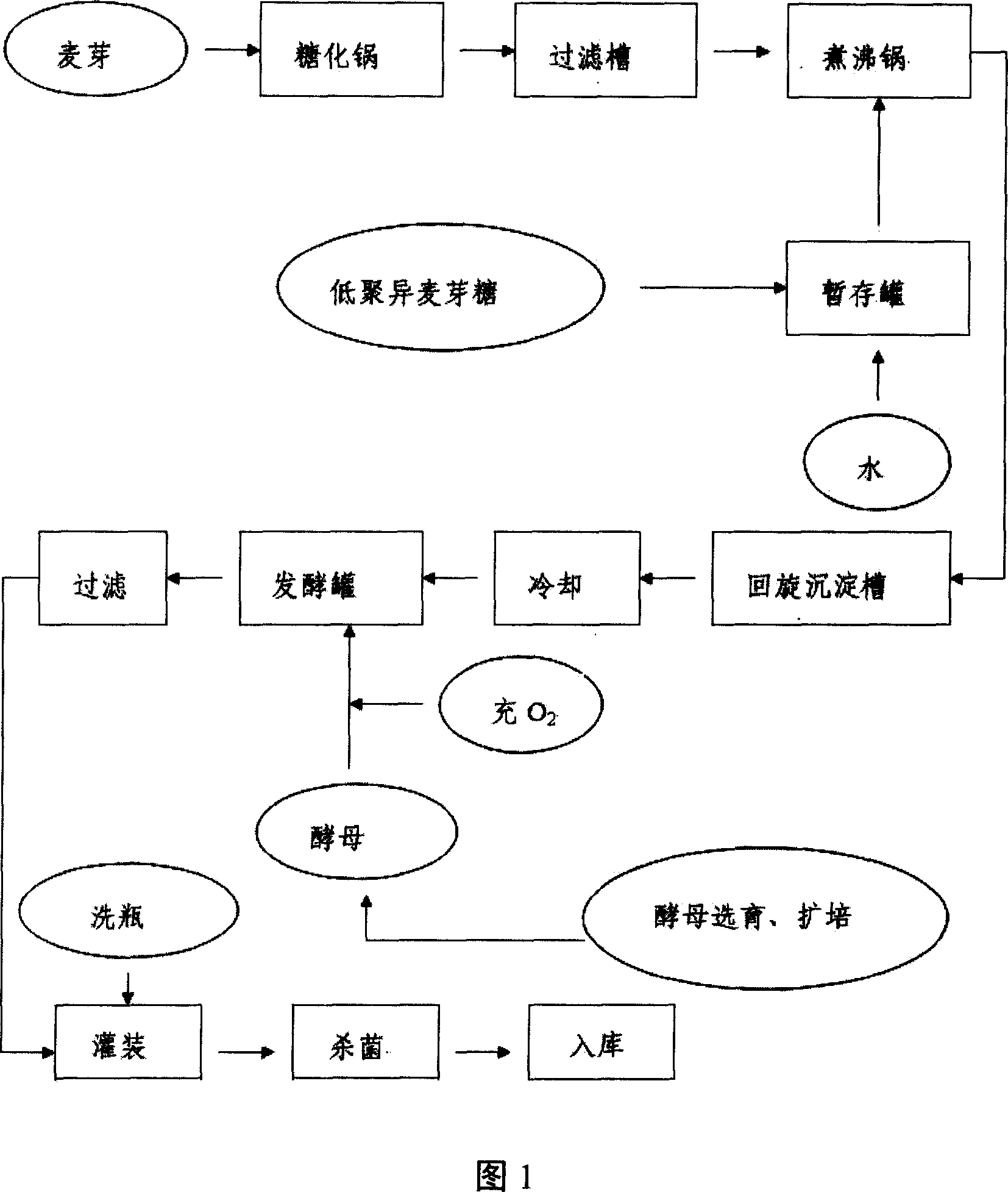

Method used

Image

Examples

Embodiment 1

[0038] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention. Embodiment 1 produces the method for low-alcohol high-concentration bifidus factor beer

[0039] Add 8000kg of Australian malt, 400hl of water, 10kg of gypsum, 20kg of compound enzyme, 1kg of beer protease, and 5000ml of phosphoric acid into the mash pot for saccharification. During saccharification, first keep warm at 46.8°C for 50 minutes, then heat up to 72.3°C for 45 minutes, and finally heat up to 76.2°C for 5 minutes.

[0040] After the saccharification is completed, it enters the filter tank. When filtering, the water temperature of the washing tank is 76.8°C, and the residual sugar is 1.3°BX.

[0041] Then enter the boiling pot to boil, add 1kg of β-acid hop oil after 15 minutes of large evaporation, add 1.5kg of carrageenan, 1.5kg of bei tannin, 2kg of β-acid hop oil after 55 minutes of large evaporation, and add 1kg of β-acid ...

Embodiment 2

[0048] Embodiment 2 produces the method for low-alcohol high-concentration bifidus factor beer

[0049] Add 8000kg of Australian malt, 400hl of water, 10kg of gypsum, 20kg of compound enzyme, 1kg of beer protease, and 5000ml of phosphoric acid into the mash pot for saccharification. During saccharification, first keep warm at 45.9°C for 50 minutes, then heat up to 72°C for 45 minutes, and finally heat up to 76.5°C for 5 minutes.

[0050] After the saccharification is completed, it enters the filter tank. When filtering, the water temperature of the washing tank is 76.5°C, and the residual sugar is controlled at 1.5°BX.

[0051] Then enter the boiling pot to boil, add 1kg of β-acid hop oil after 15 minutes of large evaporation, add 1.5kg of carrageenan, 1.5kg of bei tannin, 2kg of β-acid hop oil after 55 minutes of large evaporation, and add 1kg of β-acid hop oil 30 minutes before the end of boiling Polyisomaltose, boil time is 85 minutes. The finalized wort concentration was 1...

Embodiment 3

[0058] Embodiment 3 produces the method for low-alcohol high-concentration bifidus factor beer

[0059] Add 8000kg of Australian malt, 400hl of water, 10kg of gypsum, 20kg of compound enzyme, 1kg of beer protease, and 5000ml of phosphoric acid into the mash pot for saccharification. During saccharification, first keep warm at 46.1°C for 50 minutes, then heat up to 71.9°C for 45 minutes, and finally heat up to 76°C for 5 minutes.

[0060] After the saccharification is completed, it enters the filter tank. When filtering, the water temperature of the washing tank is 77°C, and the residual sugar is controlled at 1.6°BX.

[0061] Then enter the boiling pot to boil, add 1kg of β-acid hop oil after 15 minutes of large evaporation, add 1.5kg of carrageenan, 1.5kg of bei tannin, 2kg of β-acid hop oil after 55 minutes of large evaporation, and add 1kg of β-acid hop oil 30 minutes before the end of boiling Polyisomaltose with a boil time of 89 minutes. The final wort concentration is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com