Adjusting device

A technology of regulating device and regulating valve, applied in fuel injection device, charging system, machine/engine, etc., can solve problems such as engine damage, spring breakage, component breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

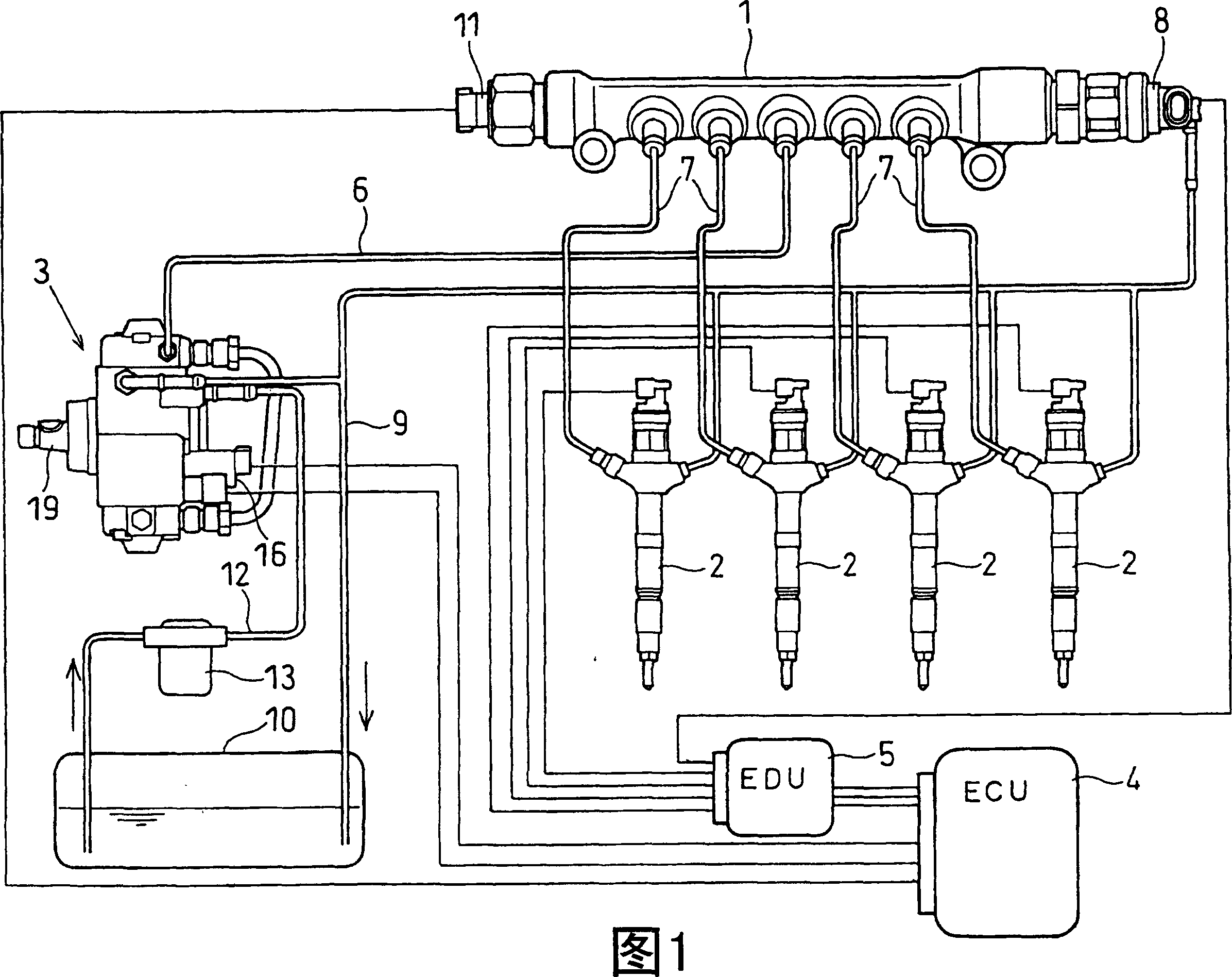

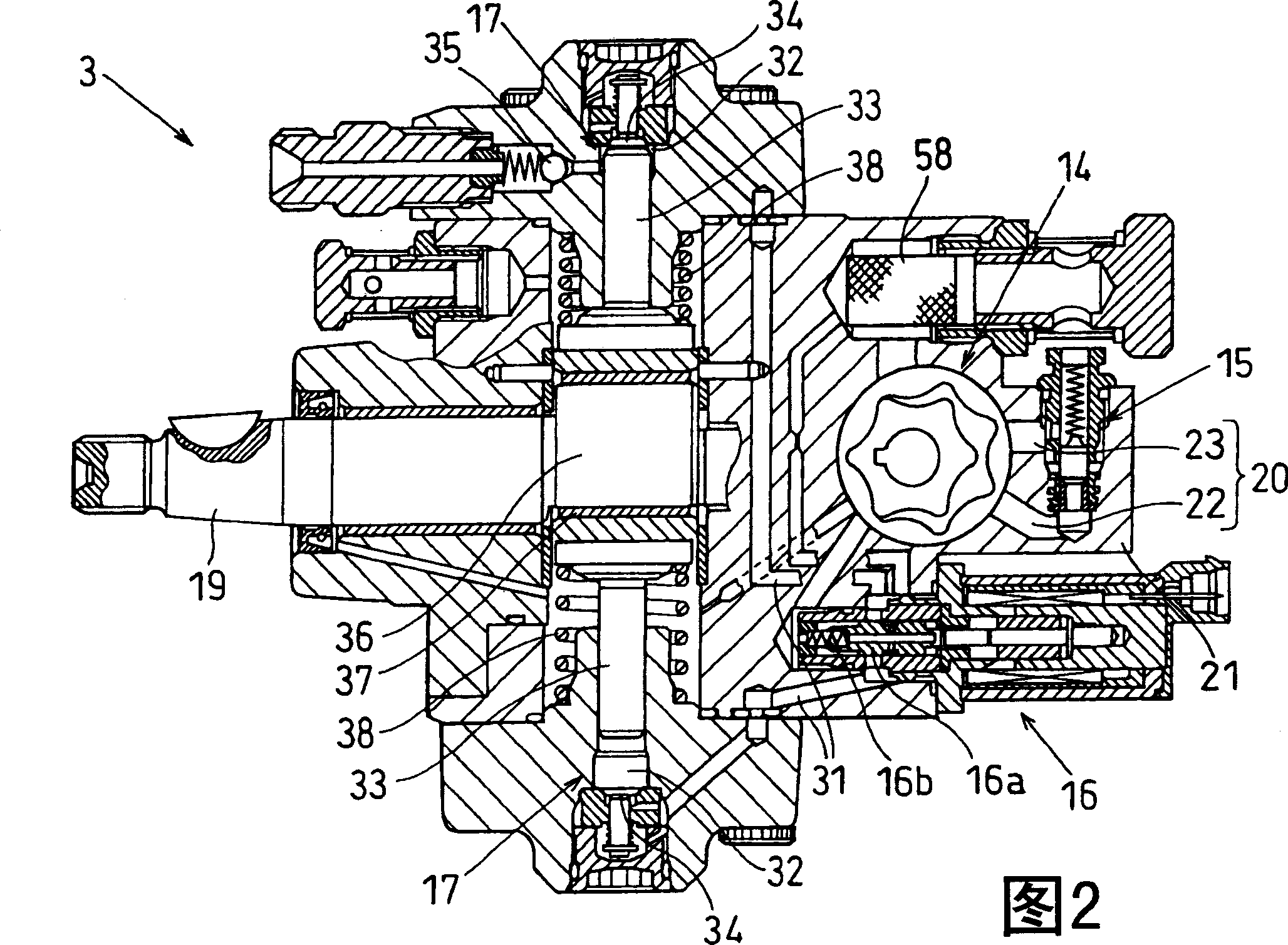

[0019] The common rail type injection system shown in FIG. 1 injects fuel into each cylinder of an engine such as a diesel engine (not shown). The fuel injection system includes a common rail 1, injectors 2, a supply pump 3, an engine control unit (ECU) 4, an electronic drive unit (EDU) 5, and the like. EDU5 may be provided in the housing of ECU4.

[0020] The common rail 1 constitutes a storage container in which high-pressure fuel to be supplied to the injector 2 is stored. The common rail 1 is connected to the discharge port of the supply pump 3 through a high-pressure pump pipe 6 for pressure-feeding high-pressure fuel. Accumulated pressure in common rail 1 (common rail pressure). This common rail pressure corresponds to fuel injection pressure. The common rail 1 is connected to a plurality of injector pipes 7 through which high-pressure fuel is supplied to the respective injectors 2 .

[0021] The pressure regulating valve 8 is also used as a pressure limiter (pressur...

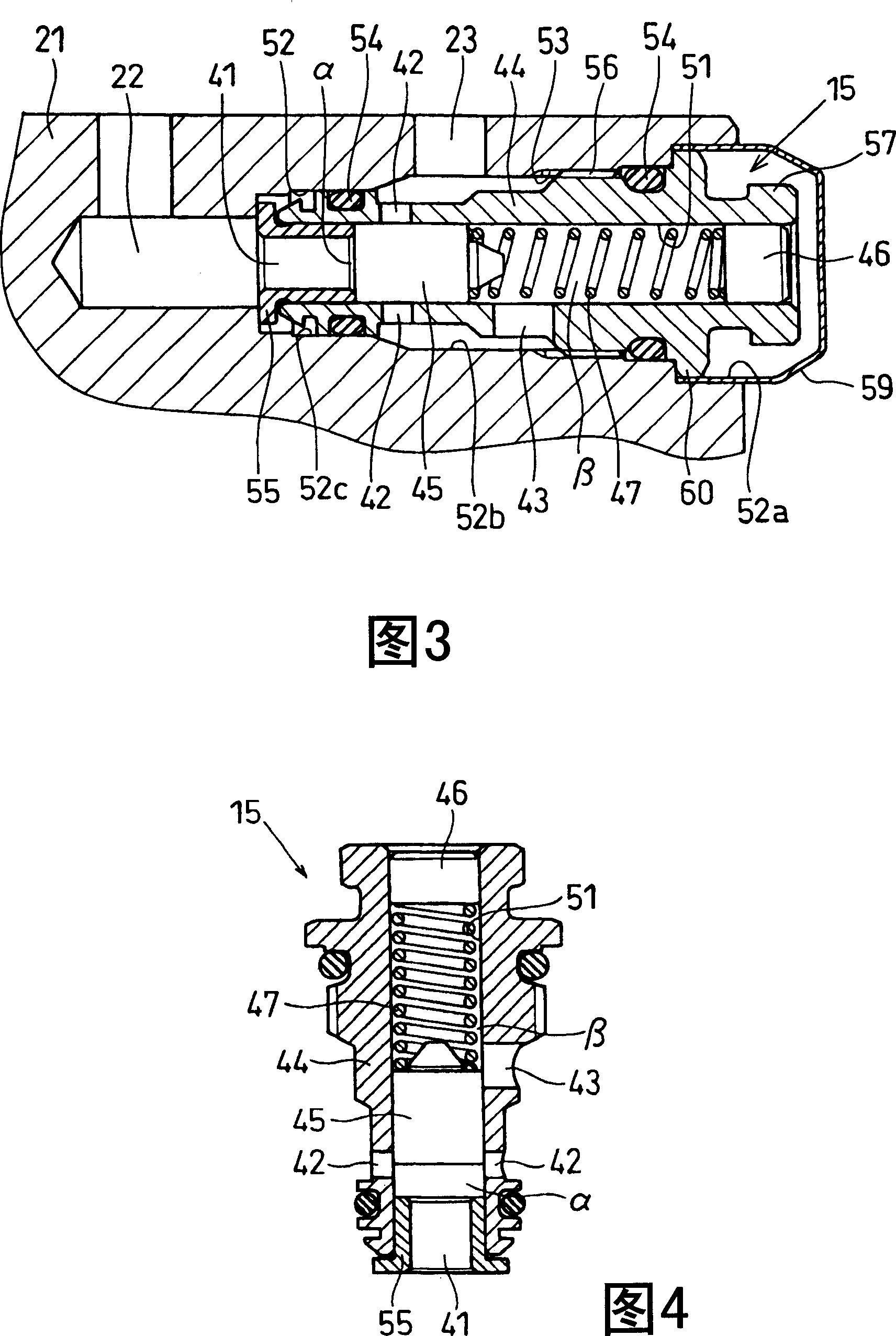

no. 2 example

[0064] As shown in FIG. 5 , the cover 59 includes a bottom in which a through hole 59 a is defined for communicating the inside and outside of the cover 59 . Similar to the first embodiment, when the plug 46 is moved in the outward direction, the plug 46 abuts against the bottom surface of the cover 59 without moving outside the cover 59 .

[0065] The through hole 59 a is arranged substantially coaxially with respect to the plug 46 . When the plug 46 moves outward relative to the valve housing 44, the engine may stop. In this state, by inserting a rod or the like into the through hole 59a to push the plug 46 into the valve housing 44, the engine can be temporarily operated. Therefore, in this embodiment, the plug 46 can be pushed back from the outside, so that the vehicle can stably perform the reverse operation.

no. 3 example

[0067] As shown in FIG. 6 , a cover 59 is fitted onto the valve housing 44 . The cover 59 is generally cup-shaped to be fitted onto the periphery of the tool fitting portion 57 . As shown in Fig. 6(a), the tool engaging portion 57 is generally elliptical to define parallel surfaces 57a, which are opposed to each other when viewed axially. The elliptical tips of the tool fitting portion 57 in the left and right sides of FIG. 6( a ) define an R portion (fitting head).

[0068] The cover 59 is formed of a soft material having a higher modulus of elasticity than the valve housing 44 so that the cover 59 is elastically deformable. Cover 59 may be formed from a thin metal sheet in a generally cup shape. A cover 59 is attached to the periphery of the tool fitting portion 57 . The cover 59 is formed by pressing, for example, stainless steel or the like. When the cover 59 is mounted on the tool fitting portion 57 , the cover 59 is pushed onto the tool fitting portion 57 to be elast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com