Ink composition for etching resist, method of forming etching resist pattern using the same, and method of formng microchannel using the ink composition

A technology of ink composition and anti-corrosion coating, applied in nanotechnology for information processing, removal of conductive materials by chemical/electrolytic methods, ink, etc., can solve problems such as expensive photoinitiators of photocurable inks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0071] Mix 10 parts by weight of urethane acryl (urethane acryl) emulsion (dry weight), 5 parts by weight of polytetrafluoroethylene dispersion solution, 10 parts by weight of glycerin, 20 parts by weight of ethylene glycol, 0.1 parts by weight of a fluorine-based surfactant and 54.9 parts by weight of deionized water were then filtered using a 1 micron filter to prepare an ink for an anti-corrosion coating. The ink exhibited a contact angle of 35° on copper surfaces and 55° on stainless steel surfaces. Consequently, the ink exhibits a larger contact angle and thus less spreading than conventional organic solvents.

preparation Embodiment 2

[0073] Mix 10 parts by weight ethoxylated glycerin acrylate, 20 parts by weight ethylene glycol, 0.1 parts by weight fluorine-based surfactant, and 69.9 parts by weight deionized water in a mixer, then use a 1 micron filter Filtration to prepare inks for anti-corrosion coatings. The ink exhibited a viscosity of 15 cP and a contact angle of 45° on a stainless steel surface. Therefore, the ink exhibits higher viscosity and larger contact angle than conventional organic solvents.

Embodiment 1

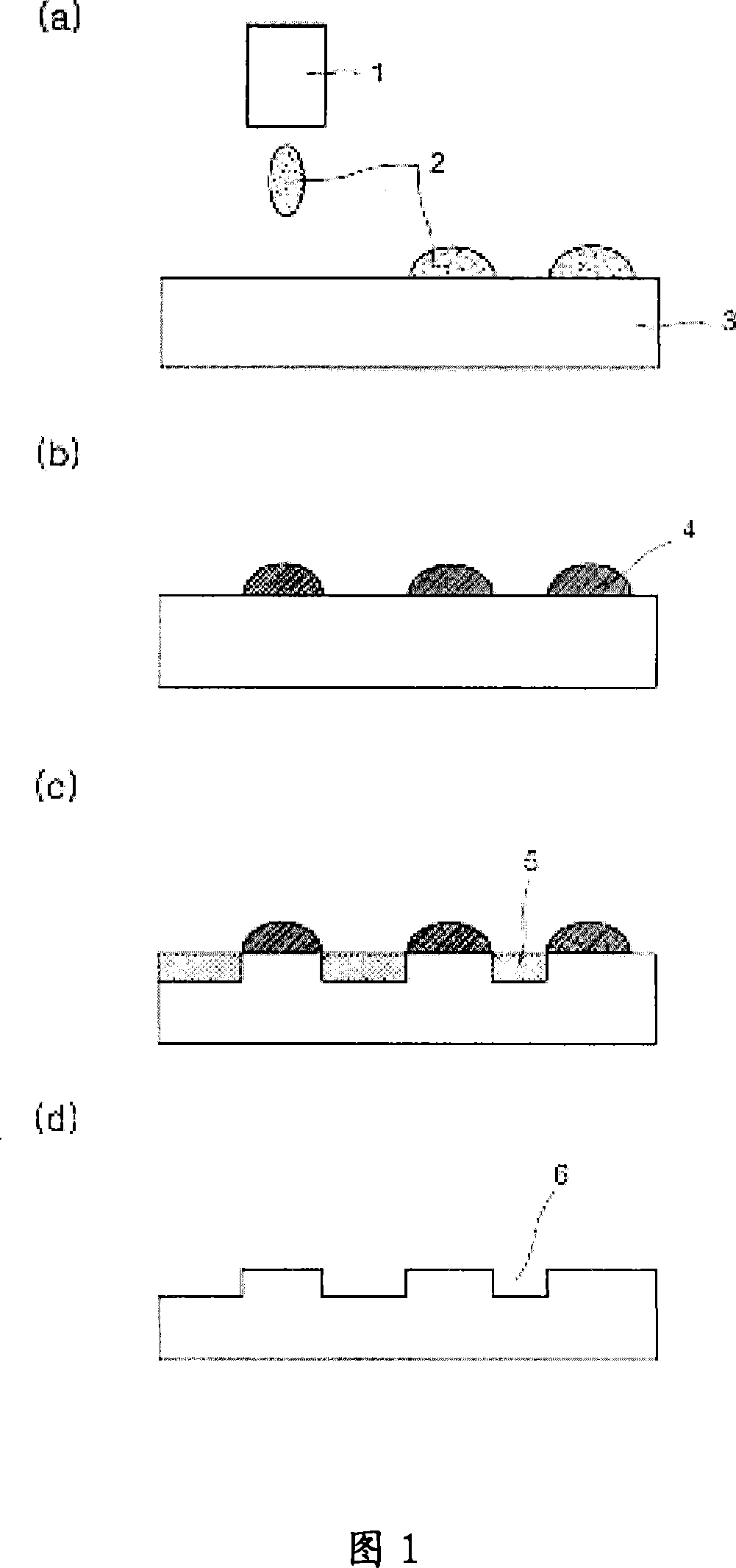

[0075] The copper substrate was cleaned with 5% aqueous hydrochloric acid and deionized water, and then dried. The ink prepared in Preparation Example 1 was sprayed onto the cleaned copper substrate using an inkjet head produced by MICROFAB, USA, to form a microchannel pattern. Then, the resulting pattern was dried on a hot plate at 80°C for 3 minutes, completely cured on an oven at 220°C for 30 minutes or more, and then etched using an etching solution containing 17 parts by weight of ferric chloride and 20 parts by weight of hydrochloric acid 30 minutes. Then, the remaining anti-corrosion coating pattern is removed by rubbing the etched pattern with acetone, so that the portion of the copper substrate not covered by the anti-corrosion coating pattern is etched to a depth of 50 micrometers or more and 50 micrometers or smaller width. As a result, a microchannel pattern is formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com