Variable high pressure strong flushing water closet bowland variable high pressure strong flushing squatting closet

A variable-type, squatting toilet technology, applied in the bathroom field, can solve the problems that the toilet occupies a large area, is not easy to popularize and apply, and cannot be changed at will, and achieves low manufacturing and transportation costs, enhanced flushing force and siphon effect, and reduced volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

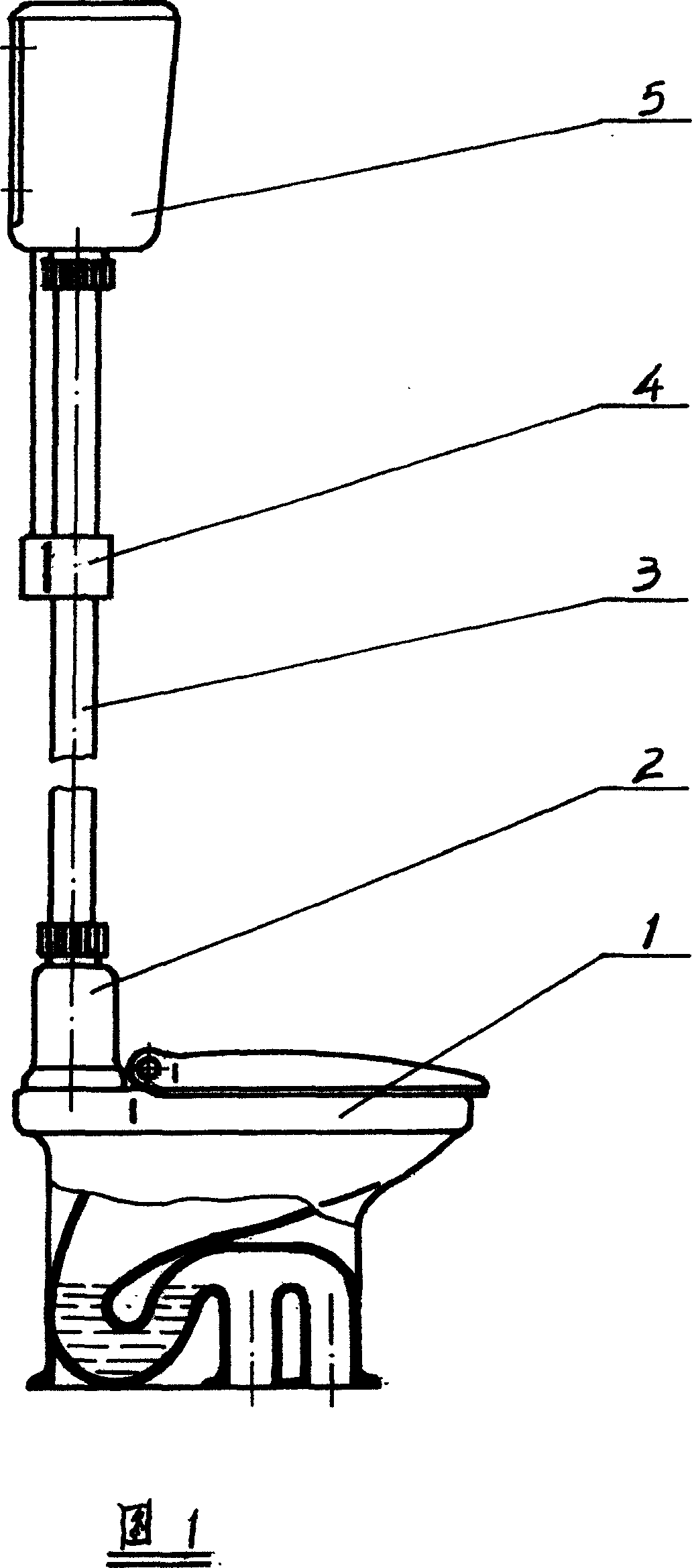

[0017] 1. Variable-type high-pressure flush toilet: as shown in Figure 1, the urinal of the toilet is made into a volute structure. The water tank is placed high close to the ceiling. A valve box with a small volume is set to be connected with the toilet, and communicated with the water tank by a standpipe. Set the flush valve and reservoir valve in the valve box. A water level control device is provided in the tank. A handle device that can change the amount of flushing water at will is arranged on the standpipe. Keep the usual seat and sink lid on the toilet.

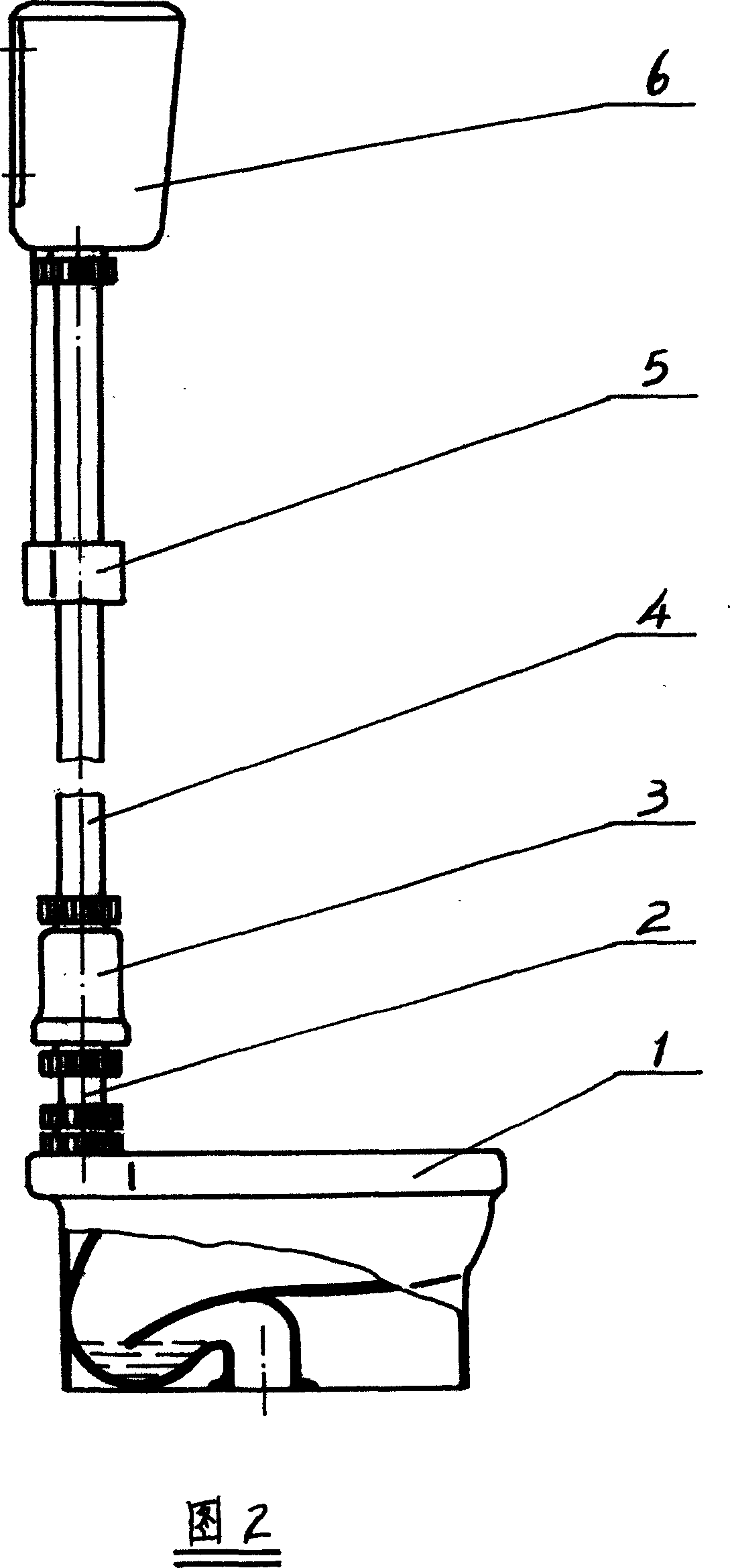

[0018] 2. Variable-type high-pressure squatting pan: as shown in Figure 2, the urinal of the squatting pan is made into a volute structure. The water tank is placed high close to the ceiling. The small-volume valve box is set to be connected with the closet by a short pipe, and communicated with the water tank by a standpipe. Set the flush valve in the valve box. A water storage valve and a water level control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com