Tearproof antiwear conveying belt

A wear-resistant and conveyor belt technology, which is applied in the field of anti-tearing, mine bulk mineral material operation, wear-resistant conveyor belt, and can solve the problems of low service life of the conveyor belt and inability to meet the requirements of mineral material operation and transportation. , to achieve the effect of reducing the number of belt changes, protecting and delaying cracking, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

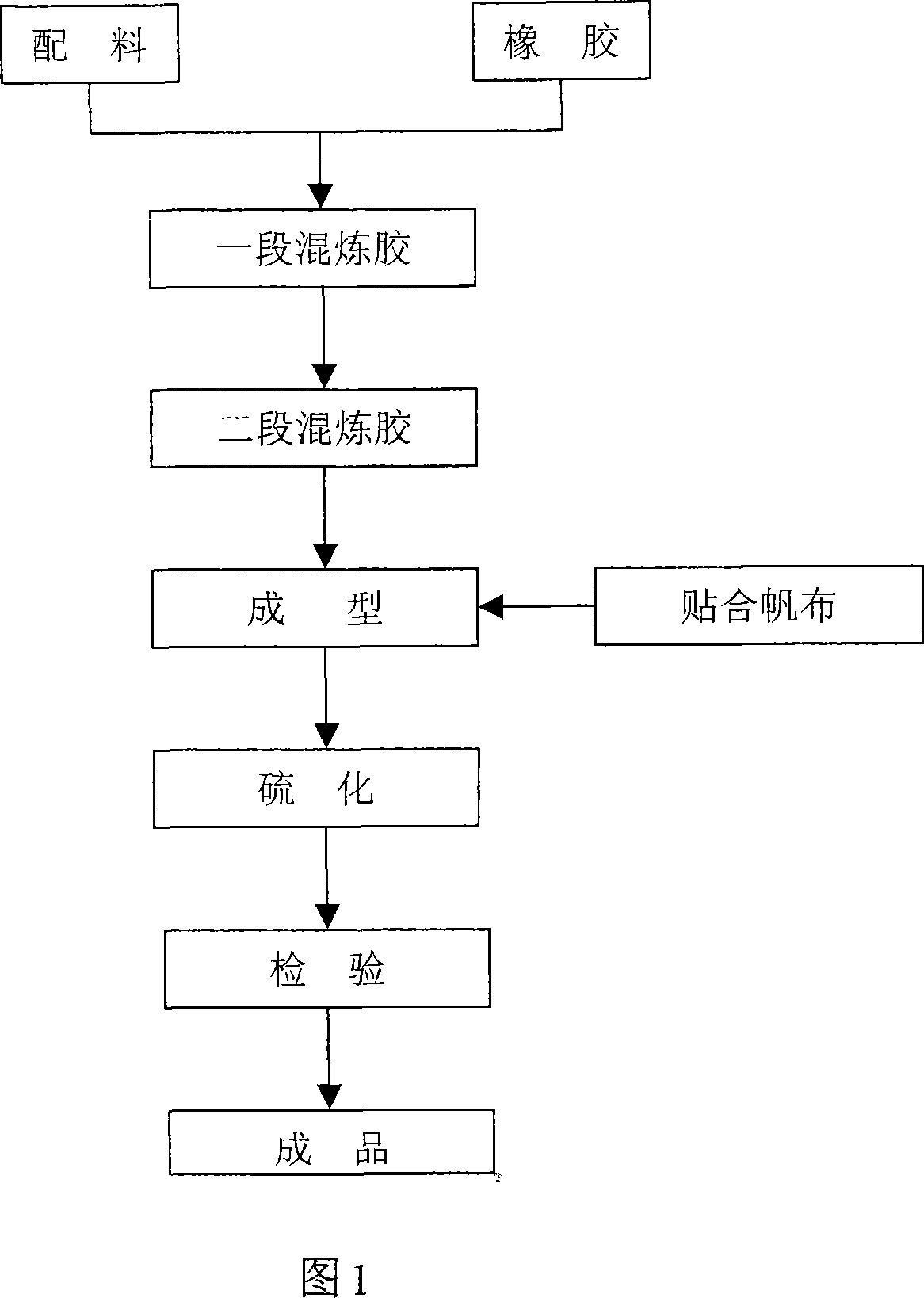

[0039] The production process of the tear-proof and wear-resistant conveyor belt of the present invention is as follows:

[0040] In the present invention, a tension-resistant body with a core is arranged between the covering rubber of the working surface and the covering rubber of the non-working surface, and they are firmly combined as a whole through molding and vulcanization processes.

[0041] The present invention mainly adopts to be provided with core tensile body between the covering rubber of the working surface and the covering rubber of the non-working surface (an additional layer of anti-tear net or tear-proof wire rope can be added under the covering rubber of the working surface, and the material can be It is metal or chemical fiber), and they are firmly combined as a whole through molding and vulcanization processes.

[0042] Its composition and proportioning of the working face covering glue described in the embodiments of the present invention are in parts:

...

Embodiment 2

[0058] Its composition and proportioning of the working face covering glue described in the embodiments of the present invention are in parts:

[0059] The present invention gets natural rubber: 70 parts

[0060] Solution polystyrene butadiene rubber: 15 parts

[0061] Butadiene rubber: 15 parts

[0062] Crosslinker 1, Sulfur: 1 part

[0063] Cross-linking agent 2, 1.2 parts of dimorpholine disulfide (DTDM)

[0064] Accelerator, N-tert-butyl-2-benzothiazylsulfenamide (NS): 1.4 parts

[0065] Active agent 1, zinc oxide: 3.5 parts

[0066] Active agent 2, stearic acid: 1.5 parts

[0067] Reinforcing agent 1, carbon black (N220): 10 parts

[0068] Reinforcing agent 2, carbon black (N234): 35 parts

[0069] Antiaging agent 1, (RD) 2,2,4-trimethyl-1,2-dihydroquinoline polymer: 2 parts

[0070] Antiaging agent 2, (4010NA) N-isopropyl-N'-phenyl-p-phenylenediamine: 2 parts

[0071] Antiager 3, paraffin: 1.5 parts

[0072] Aramid staple fiber: 5 parts

[0073] Softener, arom...

Embodiment 3

[0077] Its composition and proportioning of the working face covering glue described in the embodiments of the present invention are in parts:

[0078] Take natural rubber: 90 parts

[0079] Solution polystyrene butadiene rubber: 5 parts

[0080] Butadiene rubber: 5 parts

[0081] Crosslinker 1, sulfur: 1.6 parts

[0082] Cross-linking agent 2, 1 part of dimorpholine disulfide (DTDM)

[0083] Accelerator, N-tert-butyl-2-benzothiazylsulfenamide (NS): 1 part

[0084] Active agent 1, zinc oxide: 3.5 parts

[0085] Active agent 2, stearic acid: 1.5 parts

[0086] Reinforcing agent 1, carbon black (N220): 20 parts

[0087] Reinforcing agent 2, carbon black (N234): 25 parts

[0088] Antiaging agent 1, (RD) 2,2,4-trimethyl-1,2-dihydroquinoline polymer: 2 parts

[0089] Antiaging agent 2, (4010NA) N-isopropyl-N'-phenyl-p-phenylenediamine: 2 parts

[0090] Antiager 3, paraffin: 1.5 parts

[0091] Aramid staple fiber: 5 parts

[0092] Softener, aromatic oil: 3 parts

[0093]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com