LED lamp component circuit unit and compound serial LED lamp circuit

A technology of LED light components and LED light circuits, which is applied in the direction of electric light sources, electrical components, electroluminescent light sources, etc., can solve the problems of low power dissipation, voltage stabilization effect, low reliability, and large power dissipation, and achieve maintenance The maintenance is simple and convenient, the work reliability is improved, and the failure loss is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

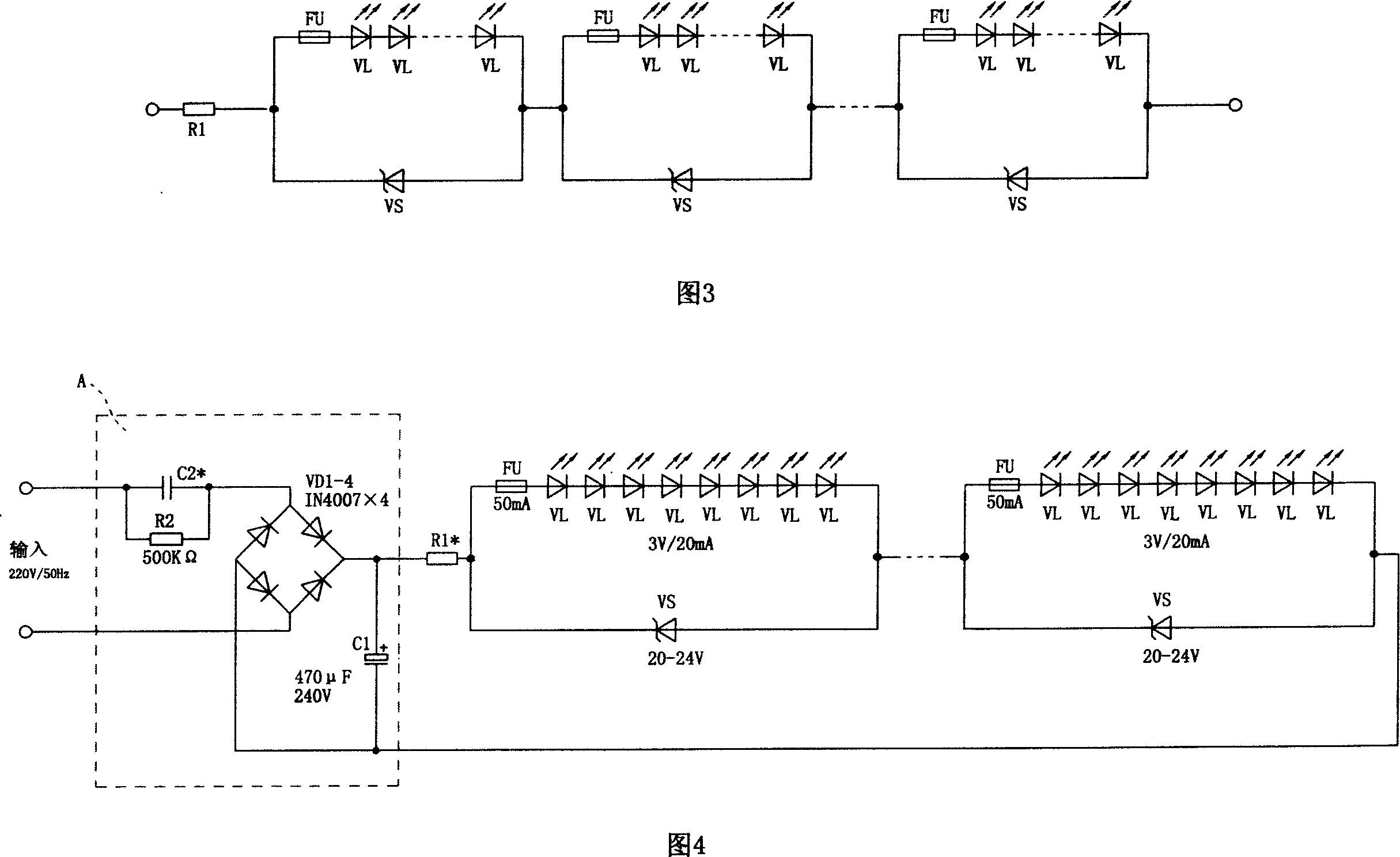

[0028] Fig. 2 is a circuit diagram of a preferred embodiment of the circuit unit of the LED lamp assembly according to the present invention.

[0029] In Figure 2, the rated voltage drop of each LED is 3 volts, the rated current is 20mA, and the rated power is 0.06W. The rated power of 8 LEDs is 0.48W. Take 65% of the rated power to obtain the component circuit unit The rated power of the fuse is about 0.3W; the voltage stabilization value of the Zener diode is selected between 20-24V, and the power is 1W; the current value of the fuse is 50mA.

[0030] Fig. 4 is a circuit diagram of a preferred embodiment of an LED lighting circuit composed of a composite series LED lamp circuit according to the present invention.

[0031] In Fig. 4, the composite series LED lamp circuit described in the present invention is connected with the capacitance series transformation type drive circuit A.

[0032] Connected to form a series LED lighting circuit, in the LED series lighting circuit, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com