Screw lifter

A technology for screw lifts and casings, applied in hoisting devices, hoisting devices, etc., can solve problems such as short life, fatigue cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

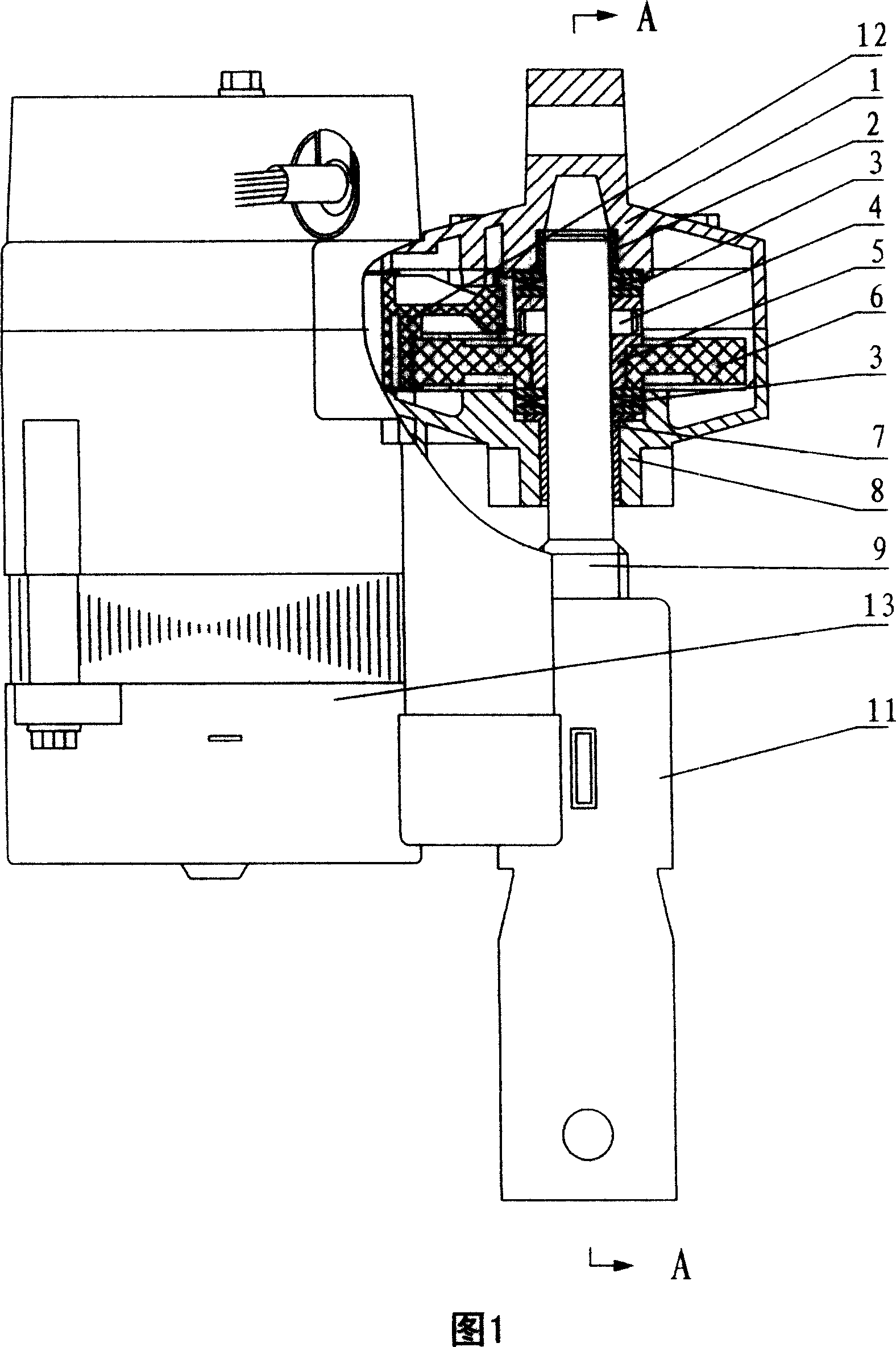

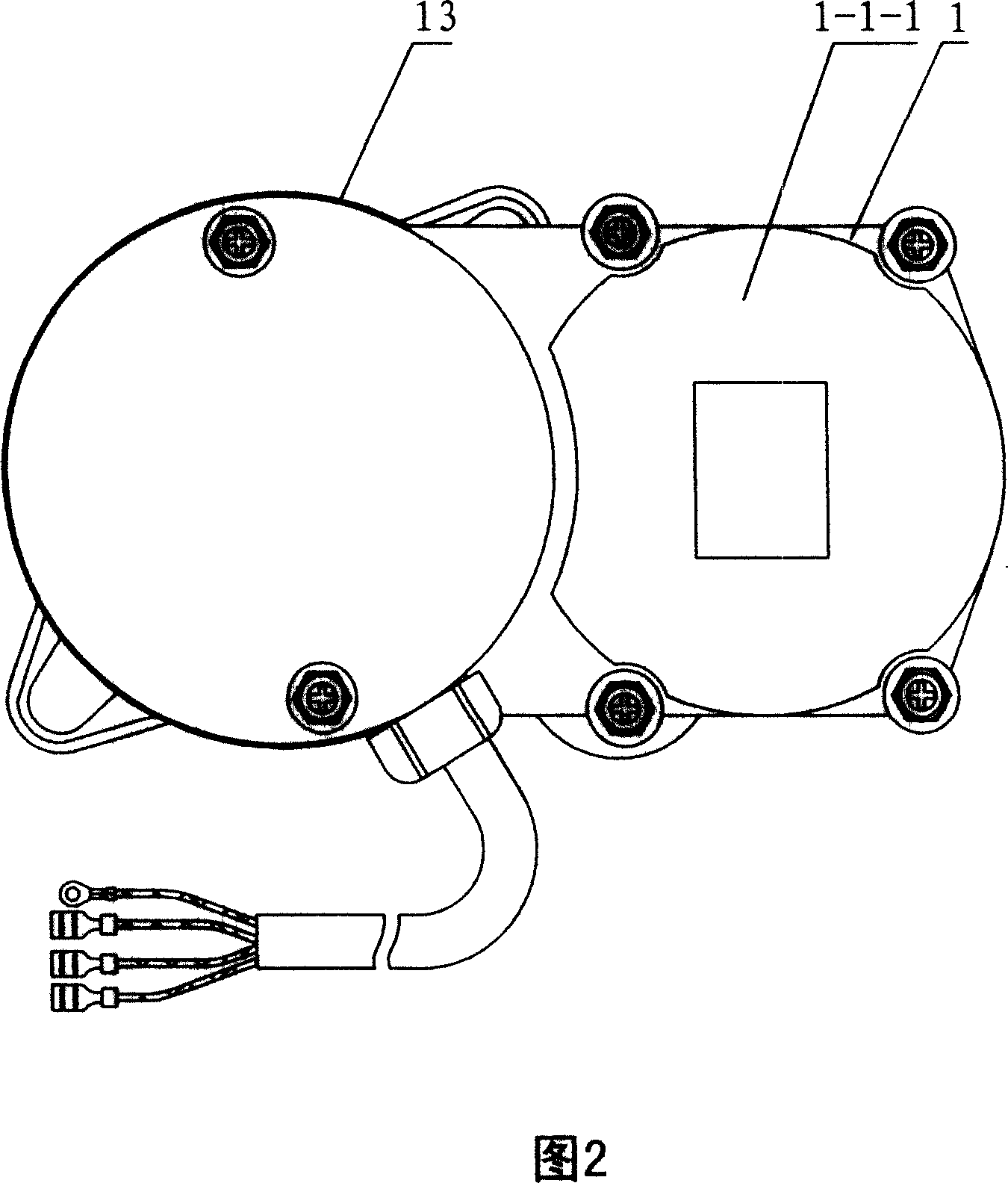

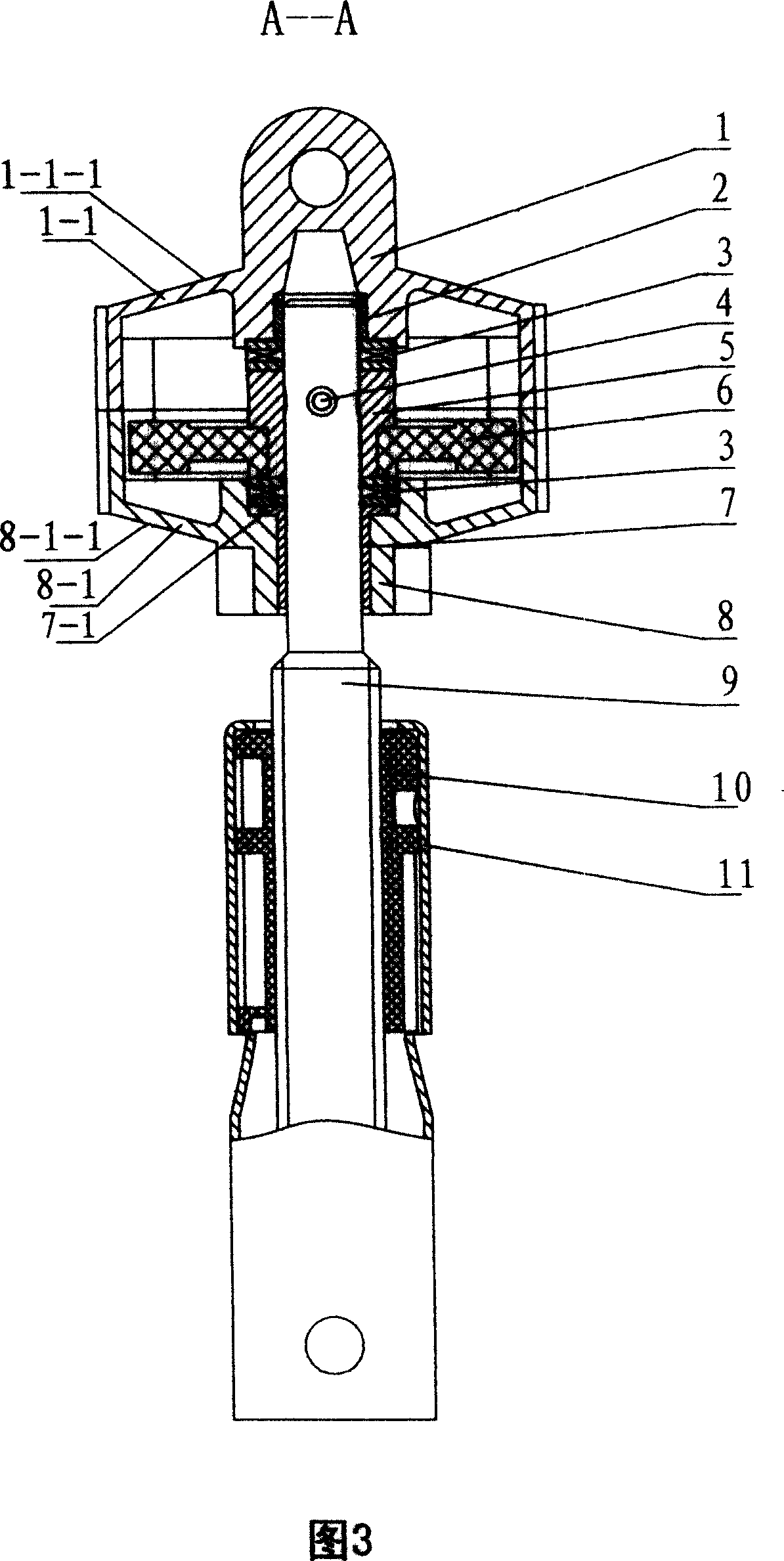

[0019] As shown in Figures 1, 2, and 3, a screw lift of the present invention, a screw lift, includes an upper casing 1, a lower casing 8, a motor 13, a deceleration assembly, bearings 2, 3, 7, and a screw rod 9 and the nut 10, the upper casing 1 and the lower casing 8 are fixedly connected, the motor 13 is connected with the screw rod 9 through the reduction assembly, the screw rod 9 is engaged with the nut 10, and the bearing housing 1 of the upper casing 1 and the lower casing 8- 2. The outer wall surfaces 1-1-1 and 8-1-1 of the housing 1-1 and 8-1 around 8-2 are conically convex. The conical convex outer wall surface 1-1-1, 8-1-1 is a conical convex surface; of course, the conical convex outer wall surface 1-1-1, 8-1-1 can also be a conical convex surface with There are ribs.

[0020] As shown in Figures 1, 3, 9, 10, and 11, in order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com