Fluid filled vibration damping device and method of producing the same

A vibration-damping device and fluid-sealing technology, applied in shock absorbers, power units, jet propulsion devices, etc., can solve problems such as damage to sealing rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

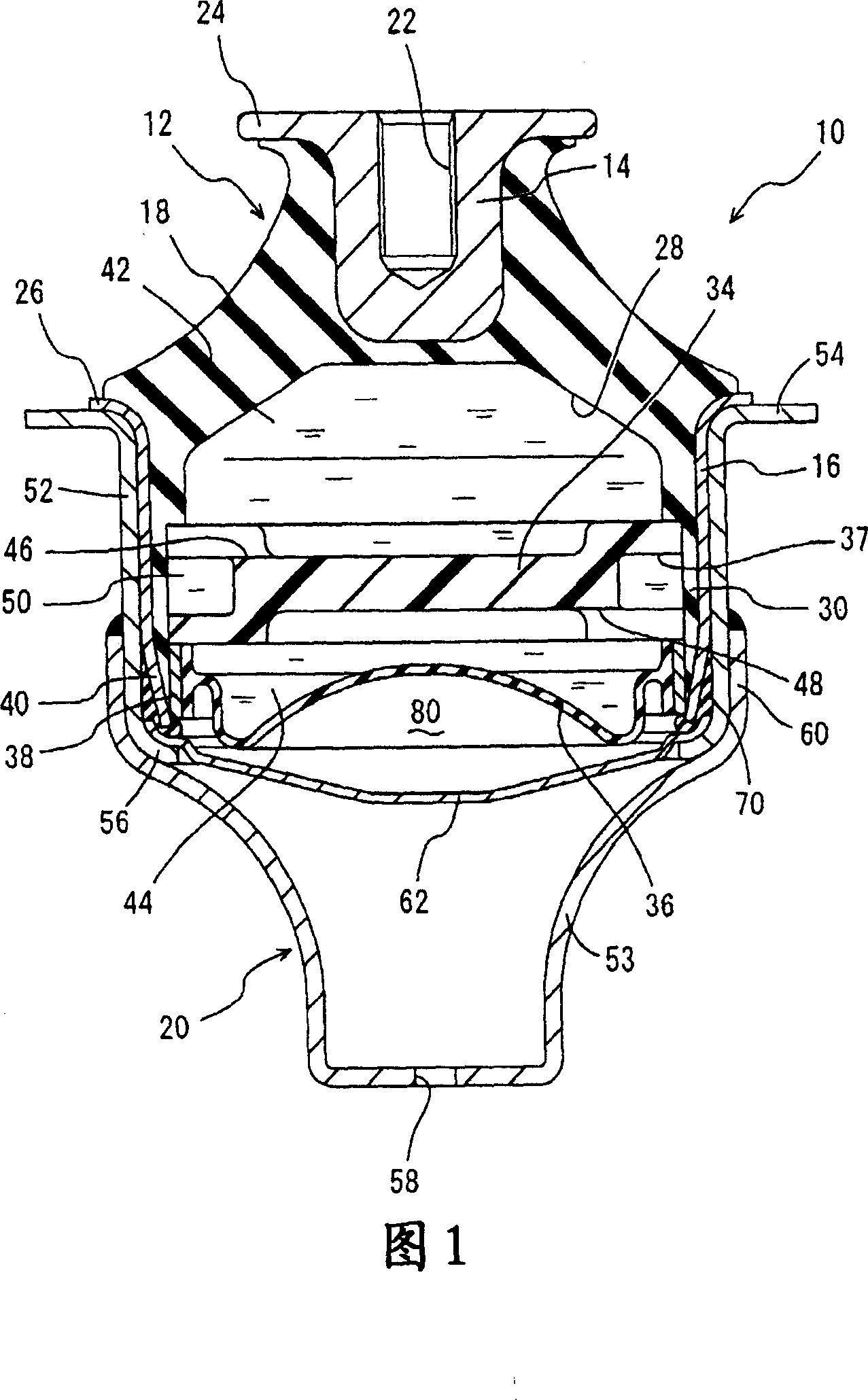

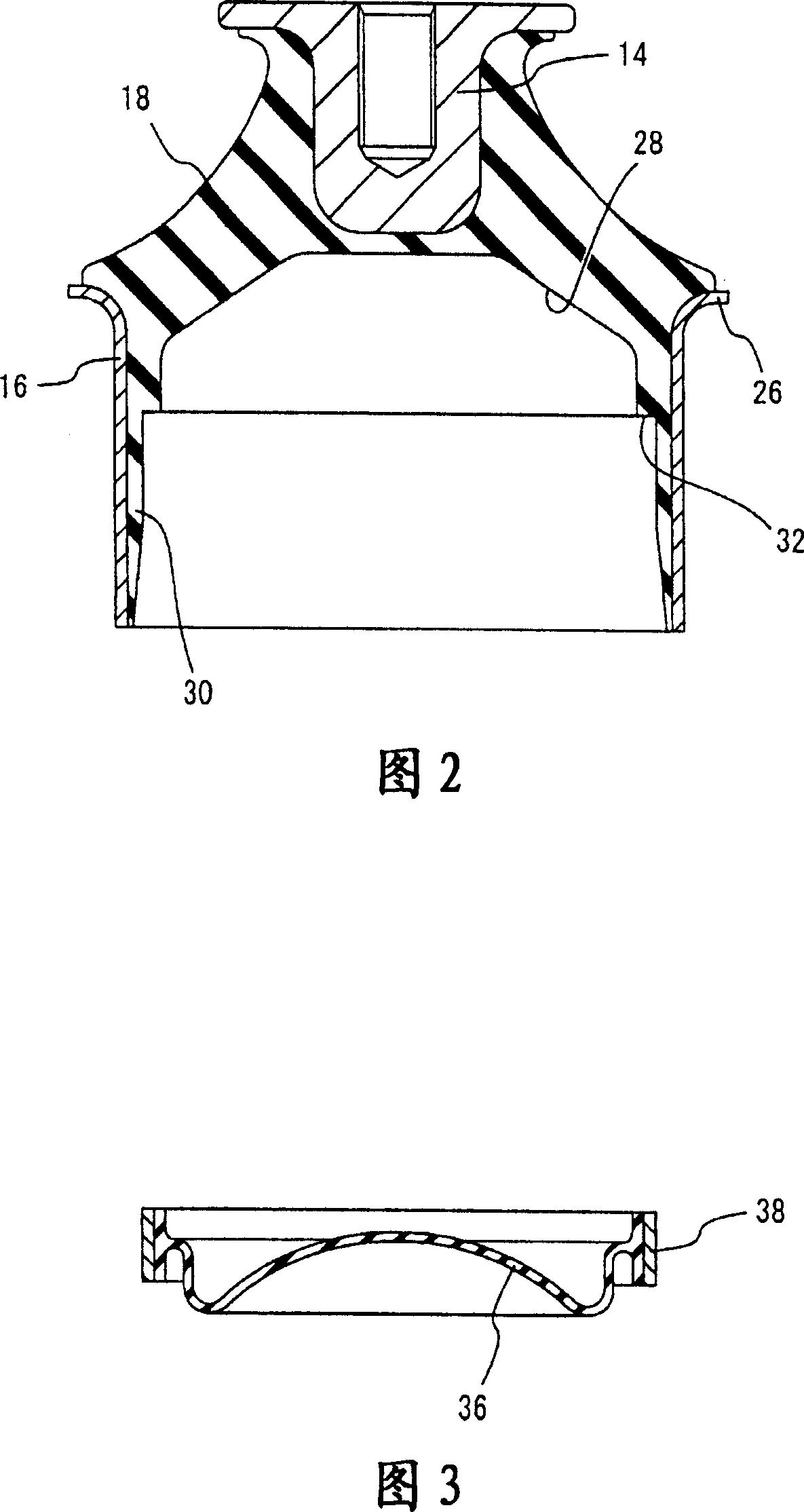

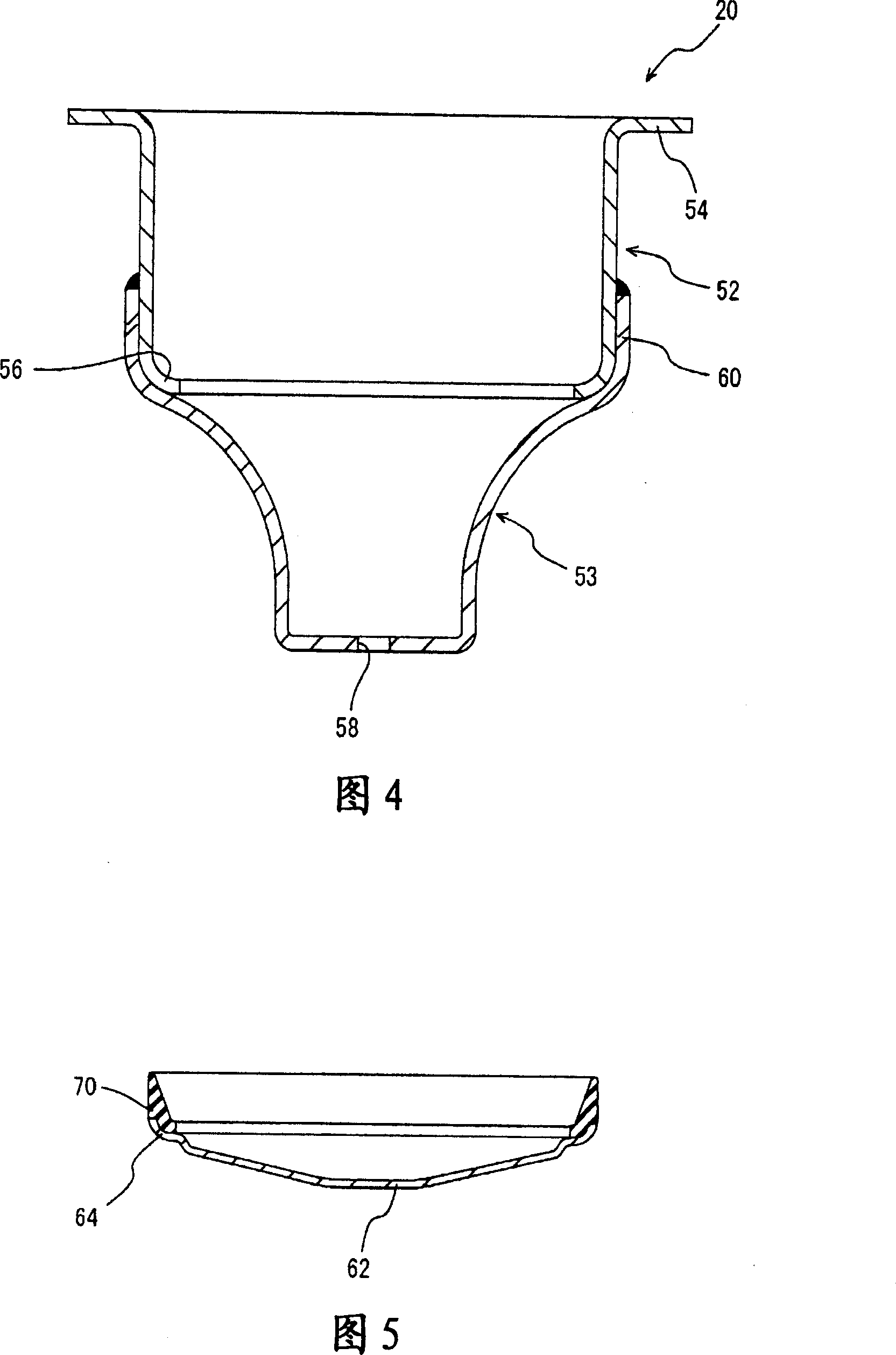

[0057] Referring first to FIG. 1, there is shown an automobile engine mount 10 belonging to a fluid-enclosed vibration damping device according to a first embodiment of the present invention. This engine mount 10 consists of a first metal mount 14 and a second metal mount 16 , which are elastically connected by a main rubber-elastic body 18 . Although not shown in the drawings, the first mount 14 is attached to the power unit assembly side, and the second mount 16 is attached to the vehicle body side of the vehicle through a bracket 20 as a holding member, so that the power unit assembly It is supported on the vehicle body in a vibration-damping manner. In the following description, the vertical direction refers in principle to the vertical direction in FIG. 1 , which represents the substantially vertical direction of the mounted mounting, ie the input direction of the main vibration load.

[0058] More specifically, the first mount 14 is a vertically extending block having a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com