Polygonal crankshaft of metering pump

A metering pump and polygon technology, applied in crankshafts, pumps, liquid variable capacity machinery, etc., can solve the problems of lower crankshaft accuracy, more time consumption, and processing difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

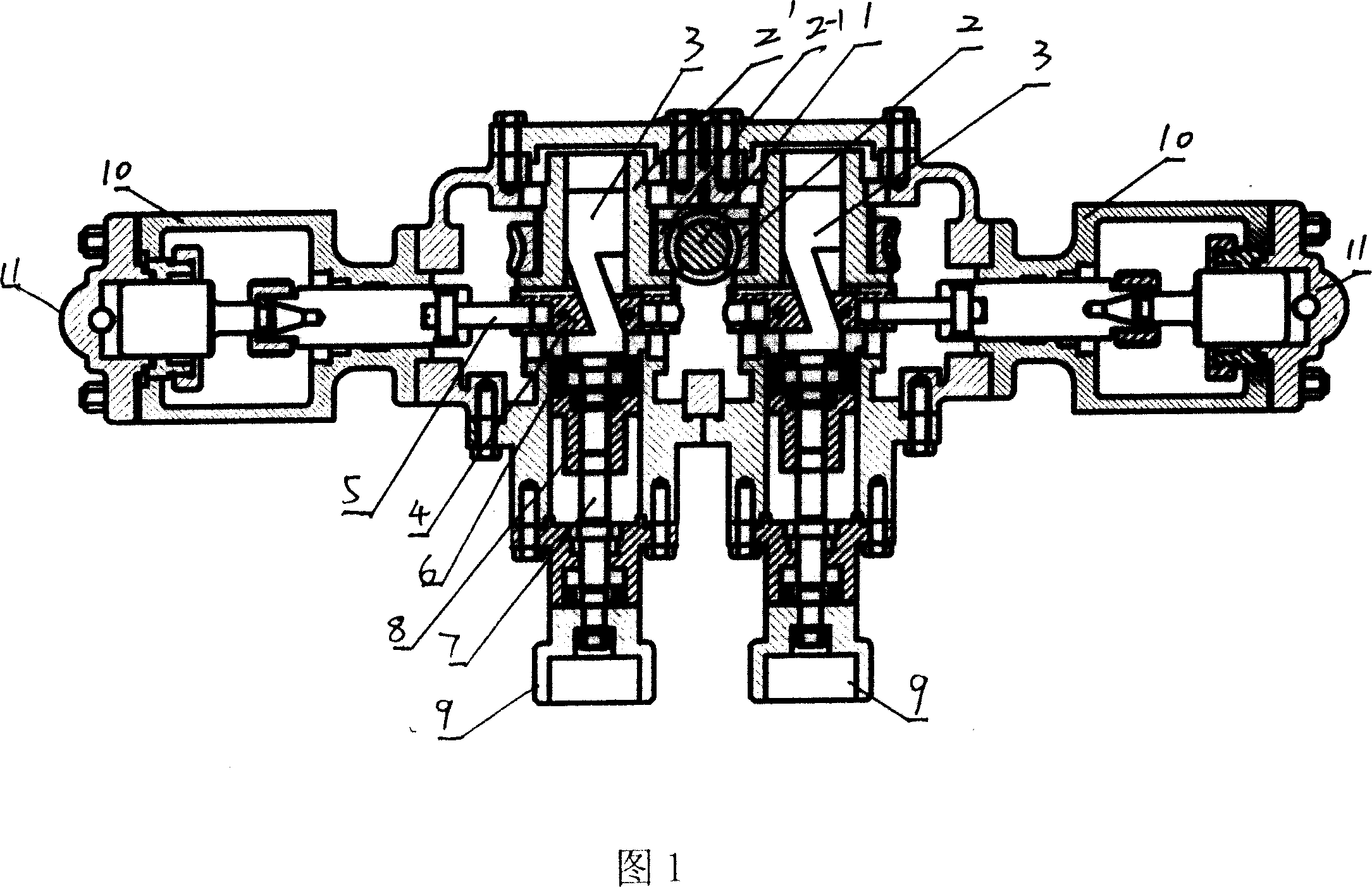

[0013] As shown in Figure 1, the metering pump is equipped with two worm gears 2, 2-1 and worm gear sleeves 2' on both sides of the worm 1. The worm gears are respectively connected to the Z-shaped crankshaft 3, and the Z-shaped crankshaft is matched with the inclined block 4. Connect, and then connect the connecting rod 5, the connecting rod is connected to the pump fluid end connector 10, the pump fluid end connector is connected to the pump head 11; the lower end of the Z-shaped crankshaft is connected to the bearing seat 6, the bearing seat is connected to the adjusting nut 8, and the adjusting nut is connected to the wire Rod 7, screw mandrel connection adjustment handwheel 9.

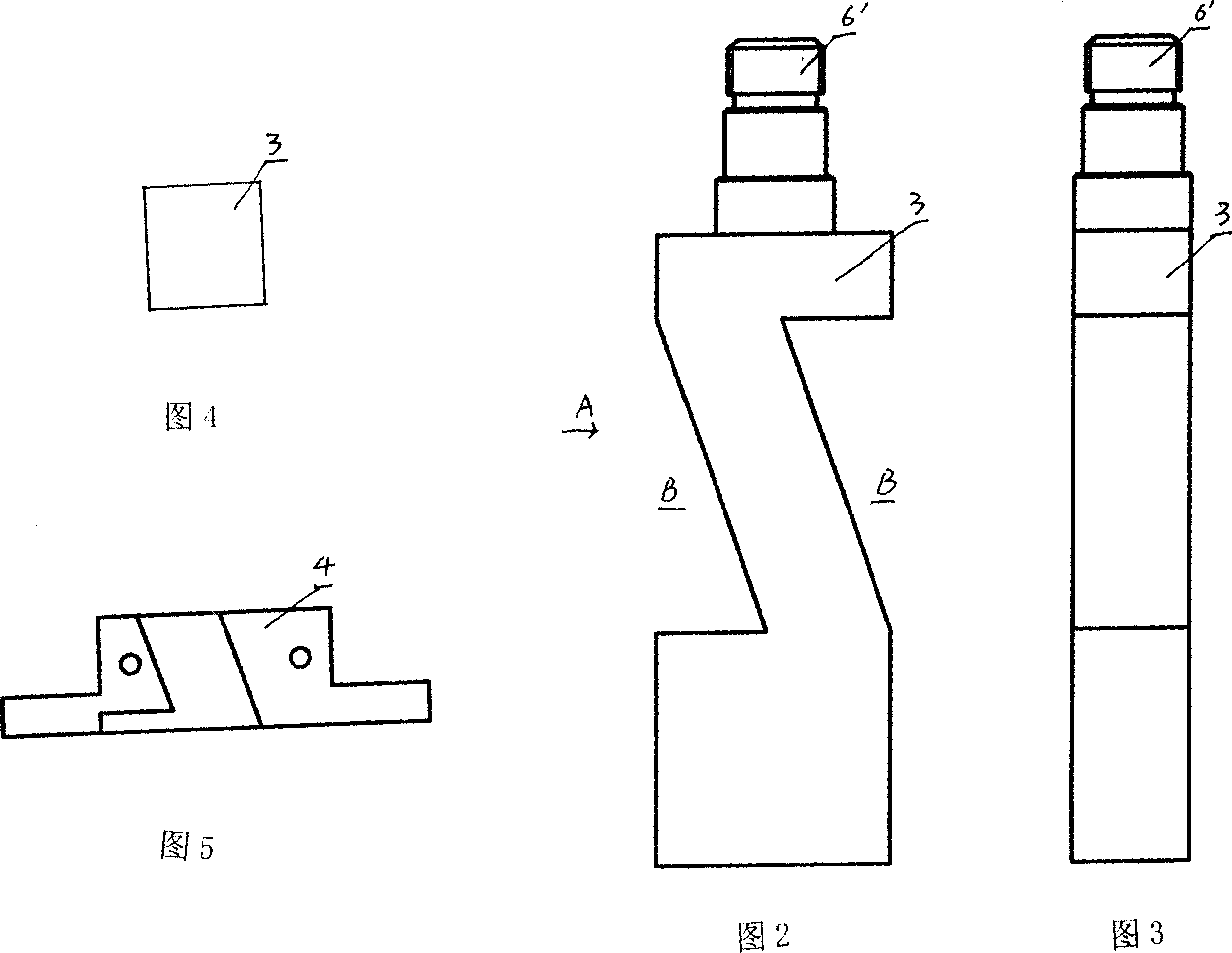

[0014] As shown in Fig. 2, Fig. 3 and Fig. 4, it is the Z-type crankshaft 3 of the metering pump, the Z-type crankshaft is connected with the bearing gear 6', and the cross section of the Z-type crankshaft is a square.

[0015] As shown in FIG. 5 , it is a slanting block 4 that is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com