Pressure detection device for hydraulic press

A detection device and hydraulic press technology, which is applied in the direction of fluid pressure measurement by changing ohmic resistance, can solve the problem of high pressure, and can only be used for hydraulic press detection and adjustment in fixed places such as production plants, and cannot meet the requirements of accurate hydraulic press detection and pressure accuracy. Adjustment, bulky cost and other issues, to achieve the effect of meeting precise requirements, facilitating debugging, and reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

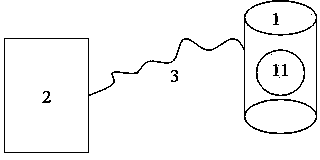

[0020] A hydraulic pressure detection device, such as figure 1 As shown, it includes a voltage changing device 1 , a display controller 2 and a cable 3 , the voltage changing device 1 and the display controller are arranged separately, and the two are connected by a cable 3 . The pressure change device is used to detect the pressure value endured in real time, convert the pressure value into an electrical signal, and transmit it to the display controller. The display controller is used to display the received electrical signal and convert it into a numerical value for display. Of course, the display controller can be calibrated before using the present invention to ensure the accuracy of measurement.

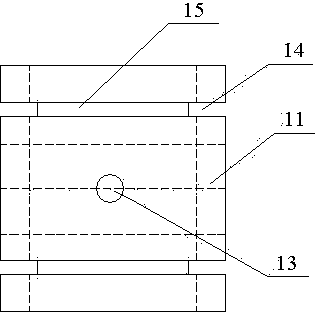

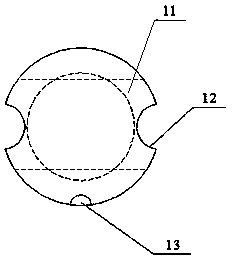

[0021] The voltage change device 1 includes an elastic strain beam, a bridge circuit and connection terminals. The elastic strain be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com