Filling wall framework heat preservation exterior block

A technology for insulating external walls and filling walls, which is applied to building components, buildings, building structures, etc. It can solve the problems of insufficient overall structural strength, easy cracks, and insufficient plastering strength of external walls, etc., and achieves a simple structure , Simple construction, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

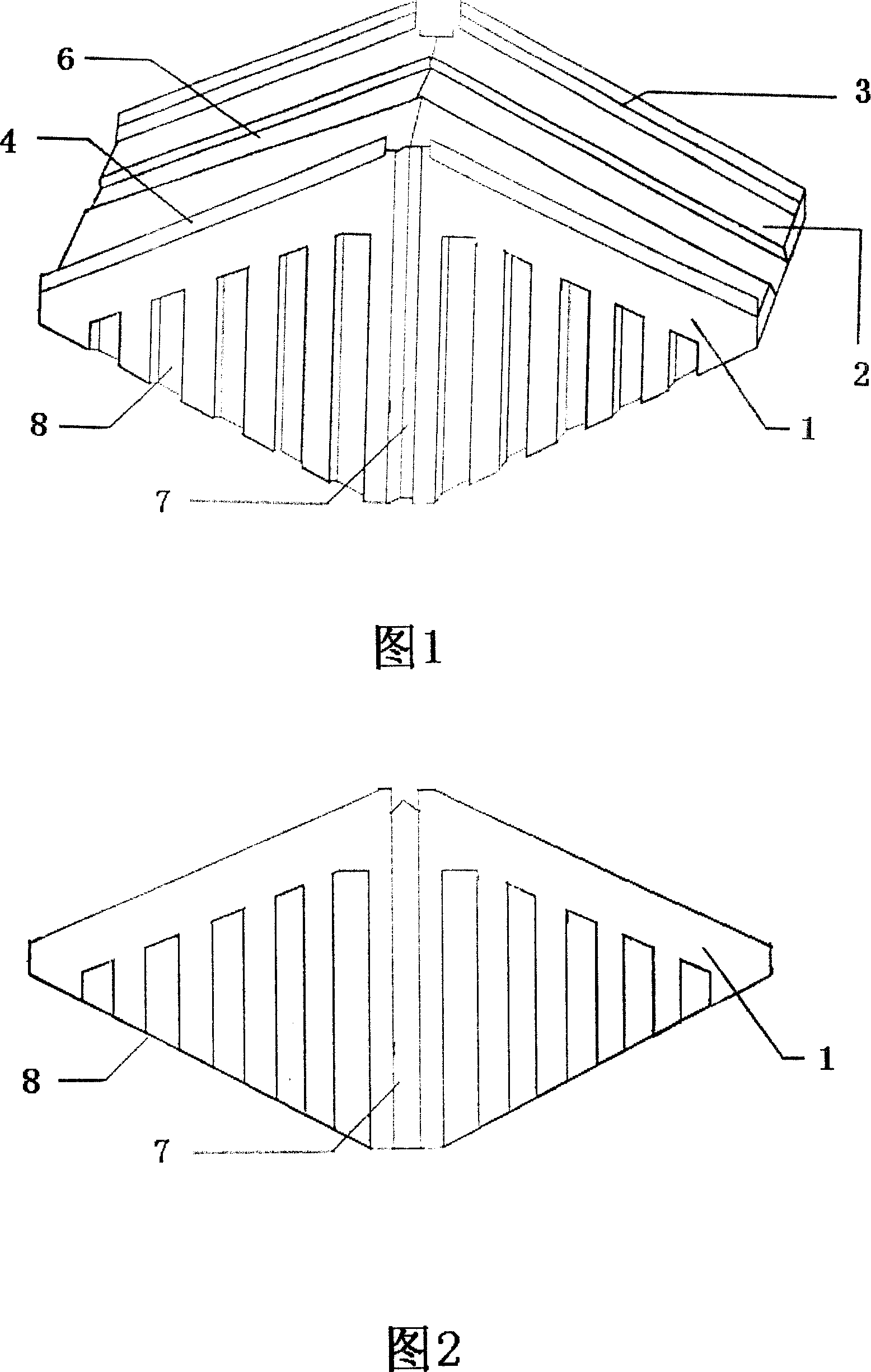

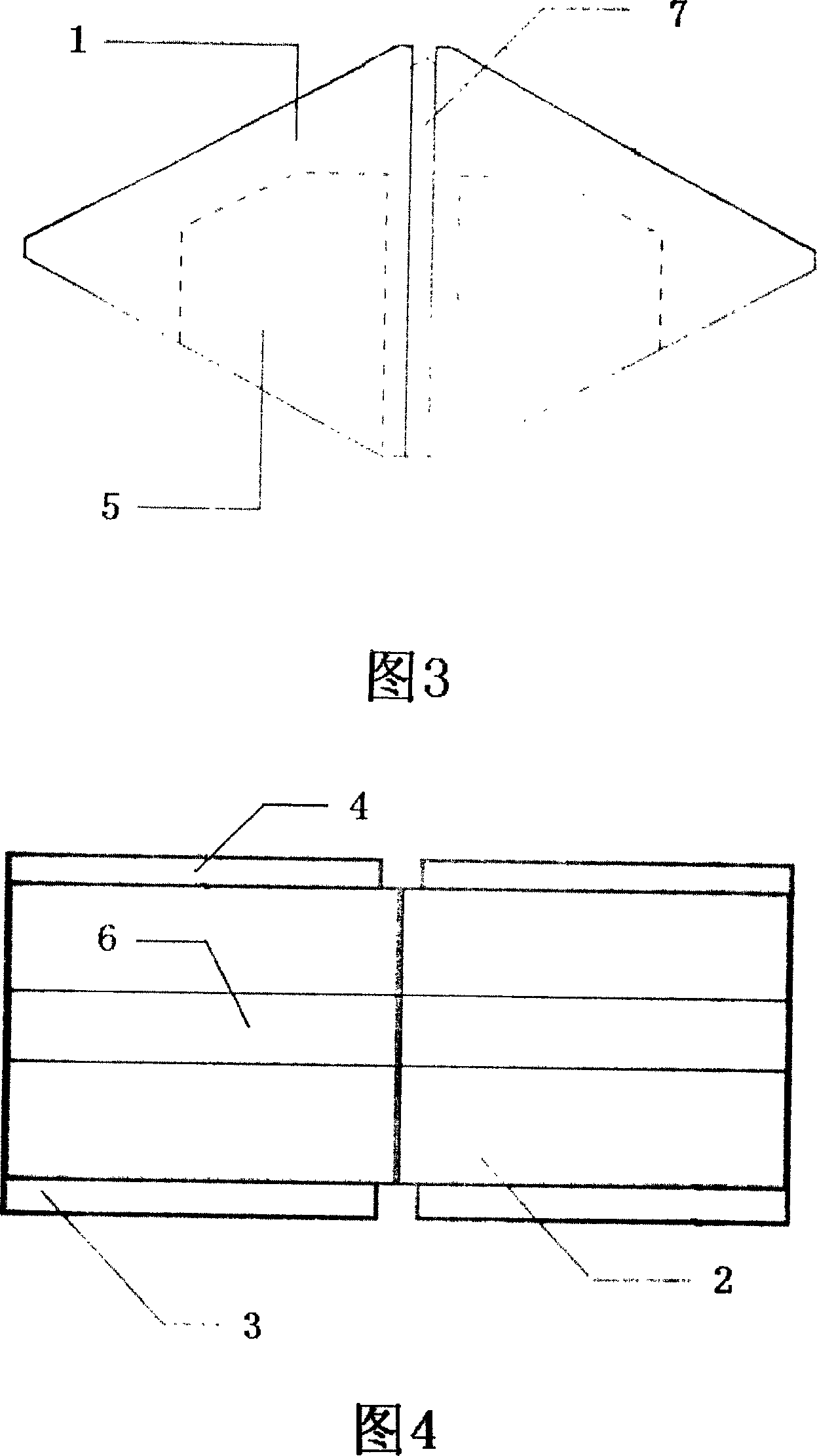

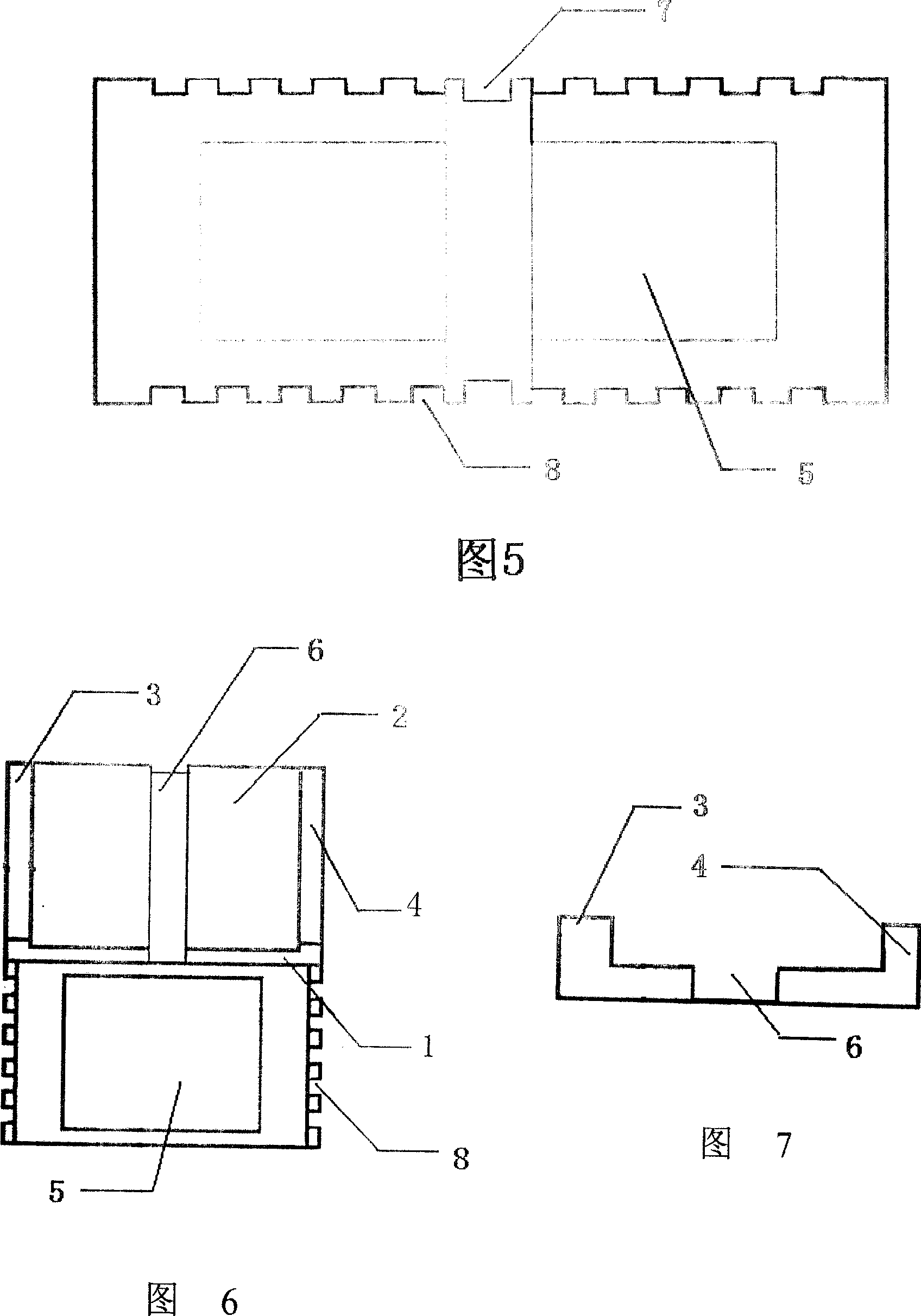

[0023] First of all, according to the needs of architectural design, polystyrene particles should be used to manufacture infill wall frame insulation external wall blocks of a certain size that meet the design requirements. Normally, the frame insulation outer wall block 1 is a diamond-shaped foam block, and the upper surface of the block 1 is provided with a groove 2 on the left and right adjacent slopes, and the two sides of the groove 2 are an outer frame 3 and an inner frame 4 . More than one masonry strengthening groove 6 is formed on the bottom surface of the groove 2 in the same direction as the groove 2, and a plastering strengthening groove 7 is vertically formed on the outer facade of the block 1 . In order to save materials and reduce costs, hollow grooves 5 are formed on the left and right adjacent slopes of the bottom surface of the block 1 . After the plastering reinforcement groove 7 is cross-condensed with the masonry surface on the upper surface, the plasterin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com