Polar coordinates numerical control highly effective milling and gear hobbing composition machine tool

A compound machine tool, polar coordinate technology, applied in the direction of gear cutting machine, gear teeth, mechanical equipment, etc., can solve the problems of single machining function of machine tool teeth, low machining efficiency, high manufacturing cost, save equipment investment, improve machining efficiency, The effect of saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

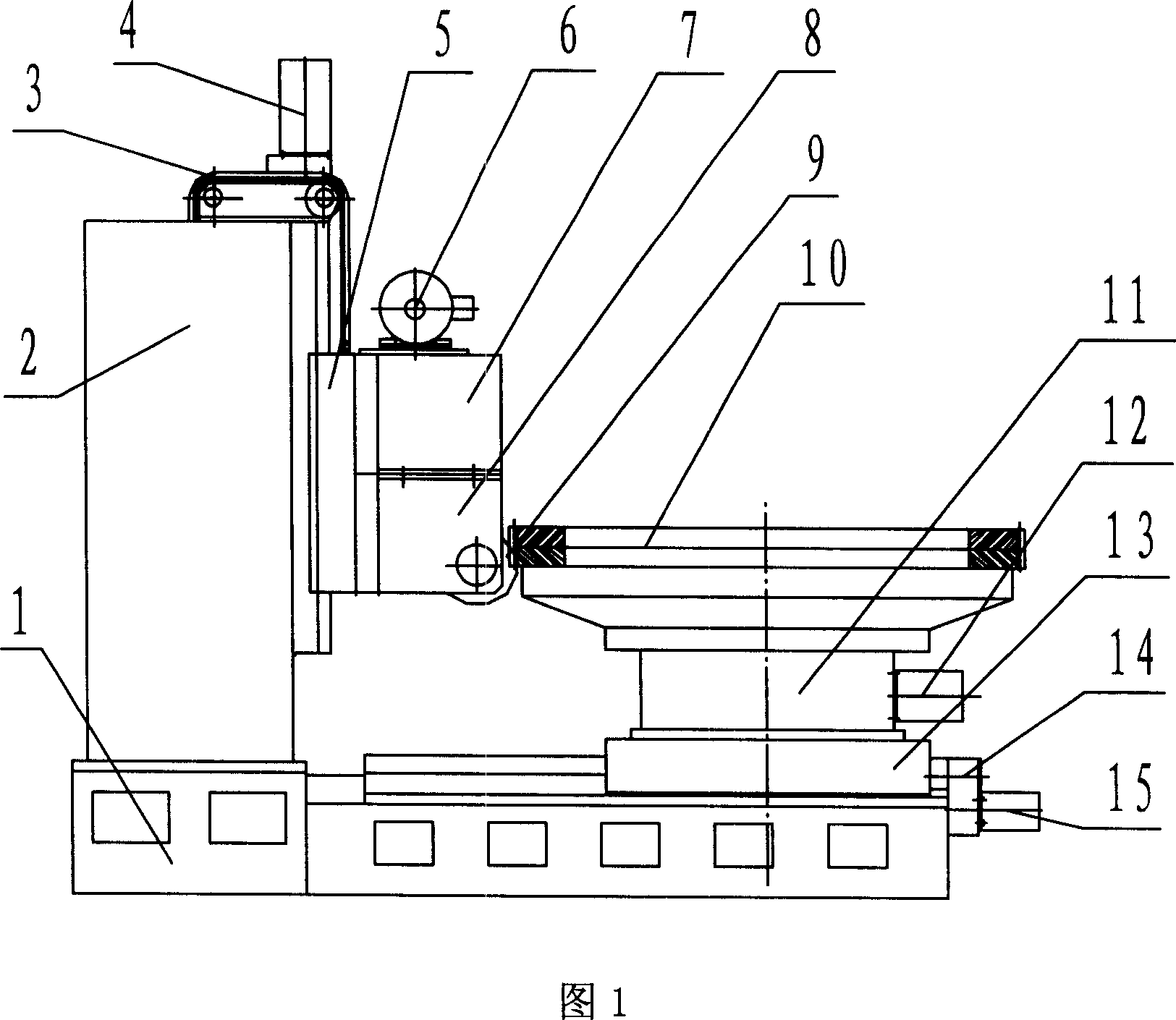

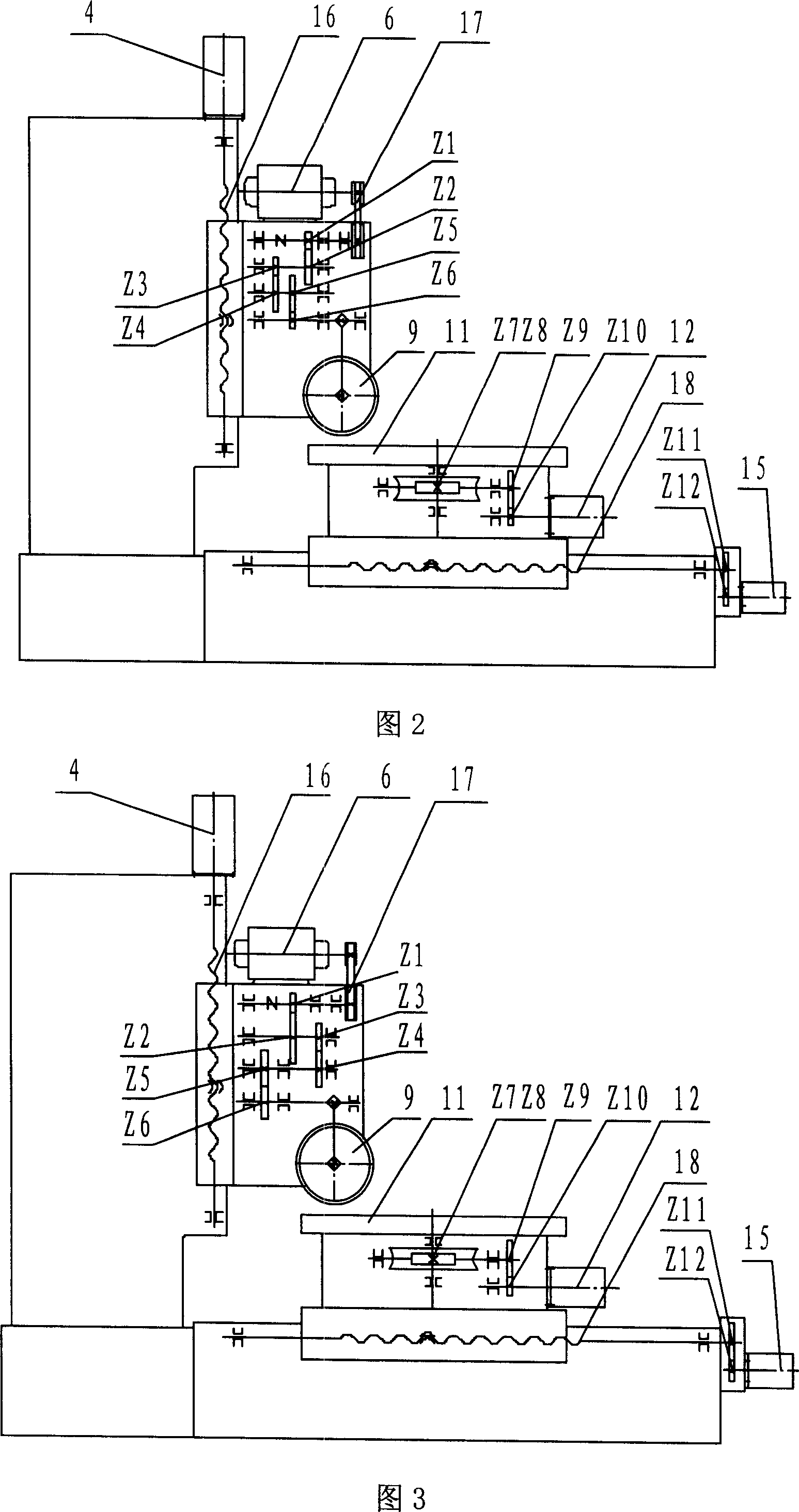

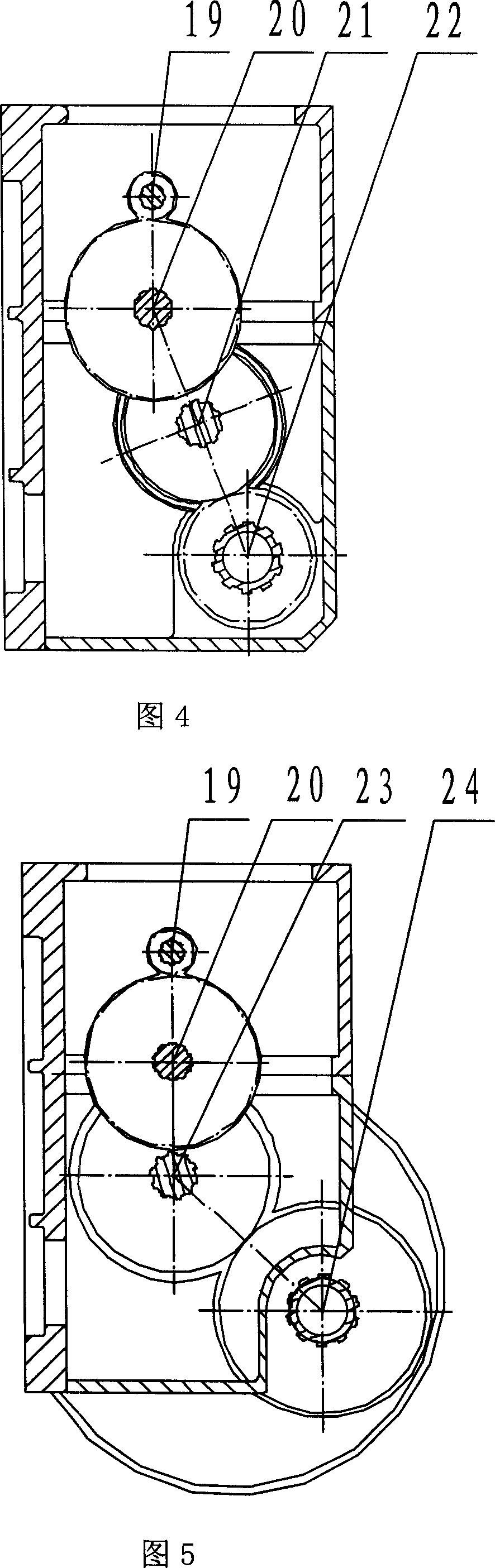

[0026] Below in conjunction with accompanying drawing, technical content of the present invention is described:

[0027]As shown in the figure, a polar coordinate CNC high-efficiency milling and gear hobbing compound machine tool of the present invention includes a bed, a column, a horizontal feed carriage, a vertical feed carriage, a rotary table and a high-efficiency milling and gear hobbing spindle The box module, the column is installed on the bed, the rotary table is fixed on the horizontal feed carriage, and the high-efficiency milling and gear hobbing headstock module is placed on the vertical feed carriage, adopting the design concept of polar coordinates, the center of the rotary table It constitutes the pole point of the workpiece processed by the polar coordinate CNC high-efficiency milling and gear hobbing machine tool. And constitute the pole diameter of the workpiece processed by the polar coordinate CNC high-efficiency milling and gear hobbing compound machine t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com