Double-group static-indeterminant mesh-beam exciting-vibration Plate type combination bearing beam oversize vibration screen

一种超静定、承重梁的技术,应用在滤筛、固体分离、格栅等方向,能够解决影响振动筛可靠性寿命和作业工艺效果、振动筛筛体横截面宽度难以加大、增加建设成本和生产管理成本等问题,达到广泛实用性、参振重量减轻、刚度大的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

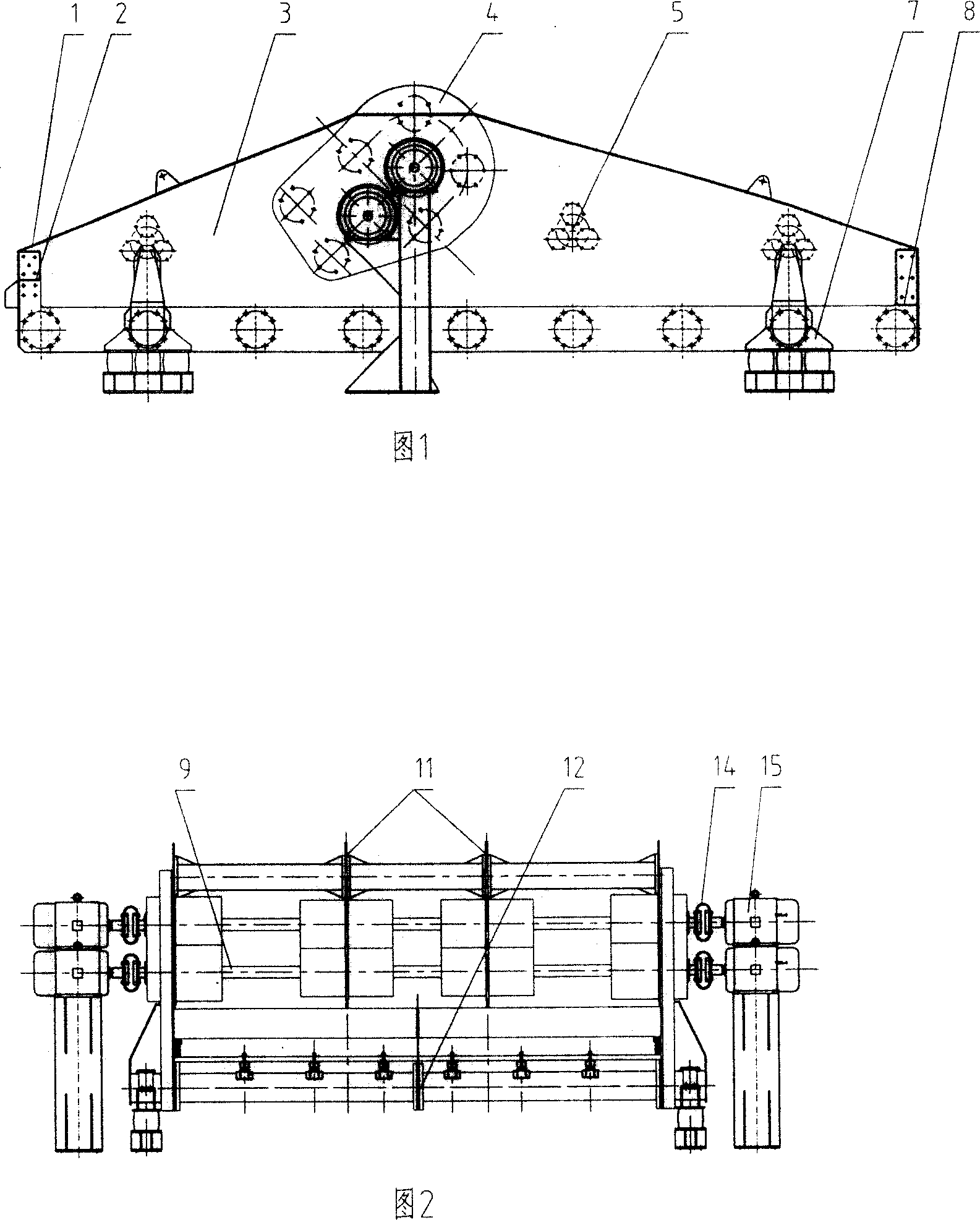

[0012] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

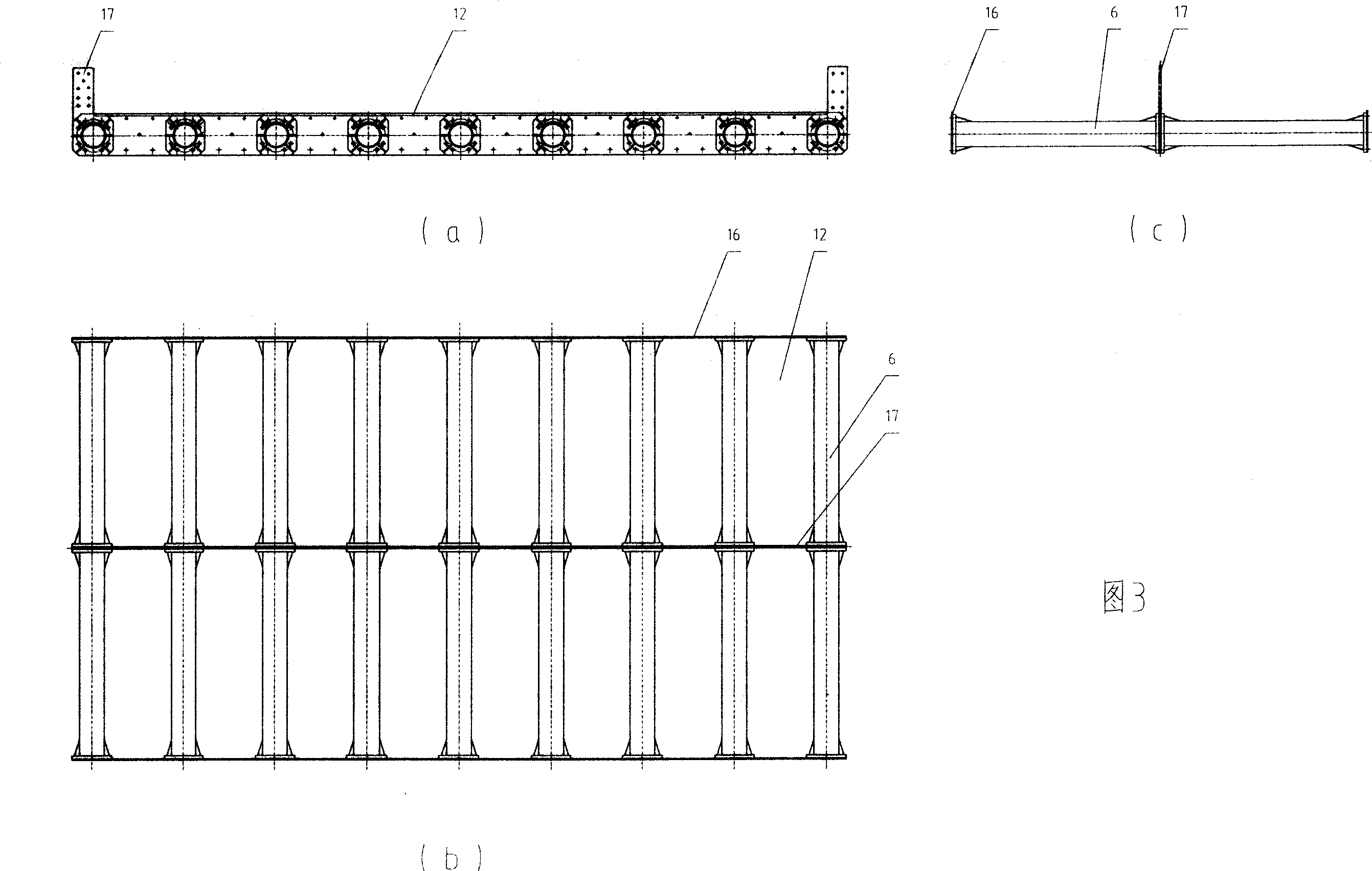

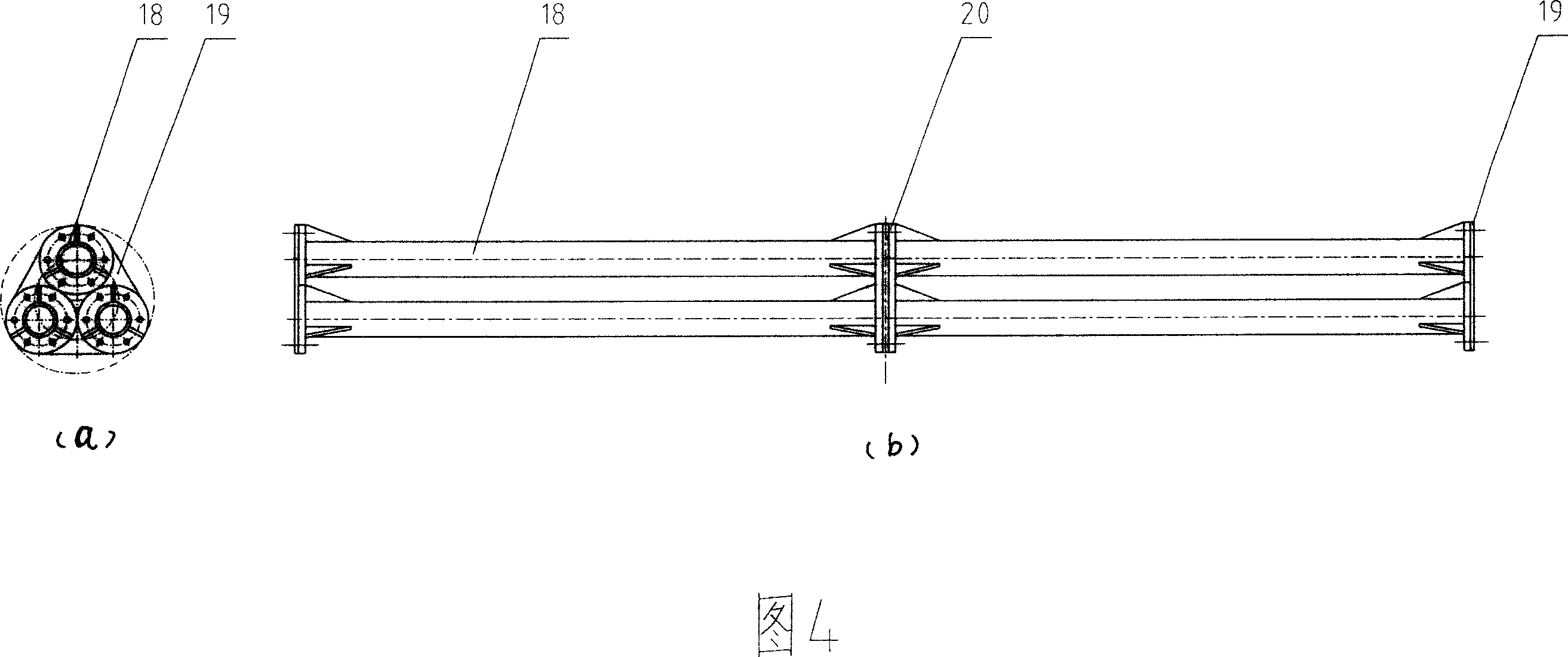

[0013] As shown in Fig. 1 and Fig. 2, the super-large vibrating screen with double sets of ultra-statically determinate mesh beams to excite plate-type combined load-bearing beams is mainly composed of a screen box 1, an elastic support body 7, a super-statically definite combined load-bearing beam 12, a motor 15, and a tire-type flexible coupling. Shaft joint 14 and ultra-static net beam device are formed, and the discharge end and feed end of screen box 1 are provided with rectangular closed beams 2 and 8 . The elastic supporting body 7 supported under the screen box 1 is composed of a spring upper seat, a rubber spring and a spring base; the super-static combined load-bearing beam 12 is arranged under the screen plate 13 in the screen box 1, and is a planar rigid body of a plate type, as shown in the figure 3 (a, b, c), it consists of statically indeterm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com