Sandwich structure and integrated formed article using the same

A technology of sandwich structure and structure, applied in the direction of layered products, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of heavy metal materials, light weight may not meet the requirements, etc., and achieve excellent mechanical characteristics , Excellent batch productivity, economical production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1-2

[0211] 30% by weight of acid-modified polypropylene resin (Yumex 1010 manufactured by Sanyo Chemical Industry Co., Ltd., acid value about 52, melting point 142°C) and 70% by weight polypropylene resin (J229E manufactured by Mitsui Chemicals Co., Ltd., melting point 155°C) , using a twin-screw extruder (TEX-30α) produced by Japan Steel Works (Co., Ltd.) to melt and knead the discs obtained at 200 ° C, and process them into a size of 350 × 350 mm and a weight per unit area of 30 g / m 2 film (F-2).

[0212] It should be noted that the melt viscosity of the disc was measured under the conditions of 160° C., preheating for 8 minutes, and a load of 10 kgf using a capillary rheometer (capillary rheometer) CFT-500D manufactured by Shimadzu Corporation, and it was 185 Pa·s.

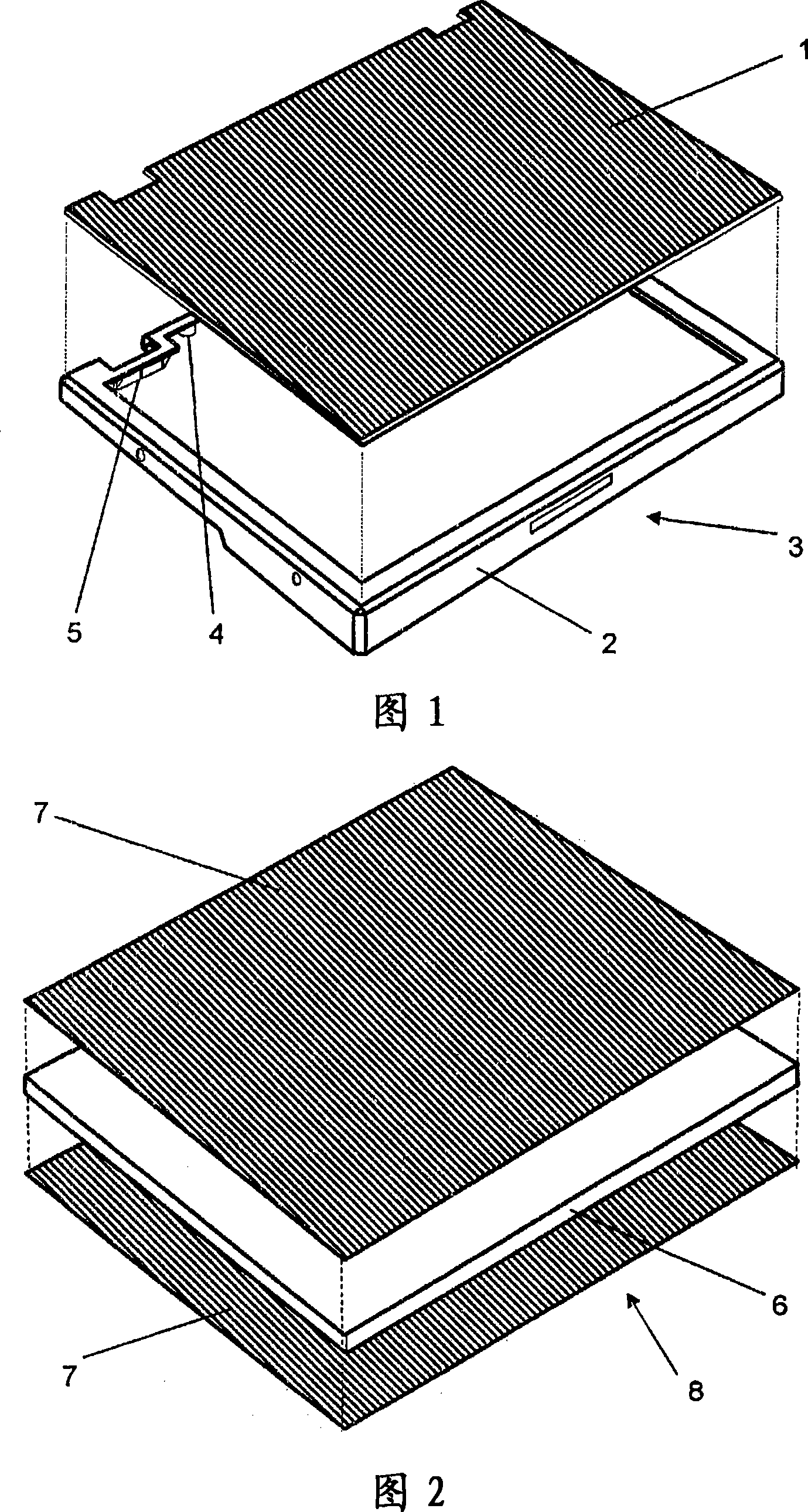

Embodiment 1

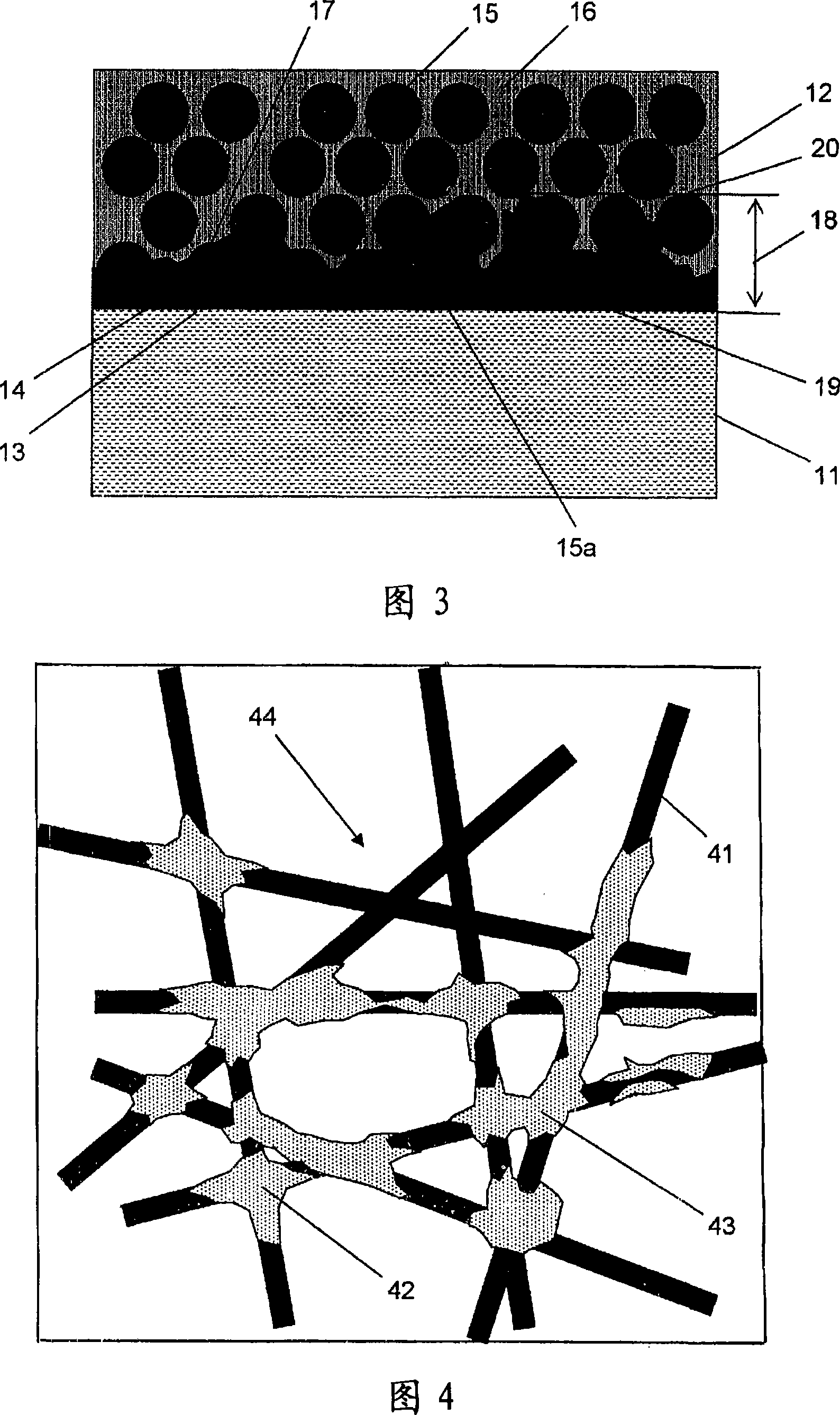

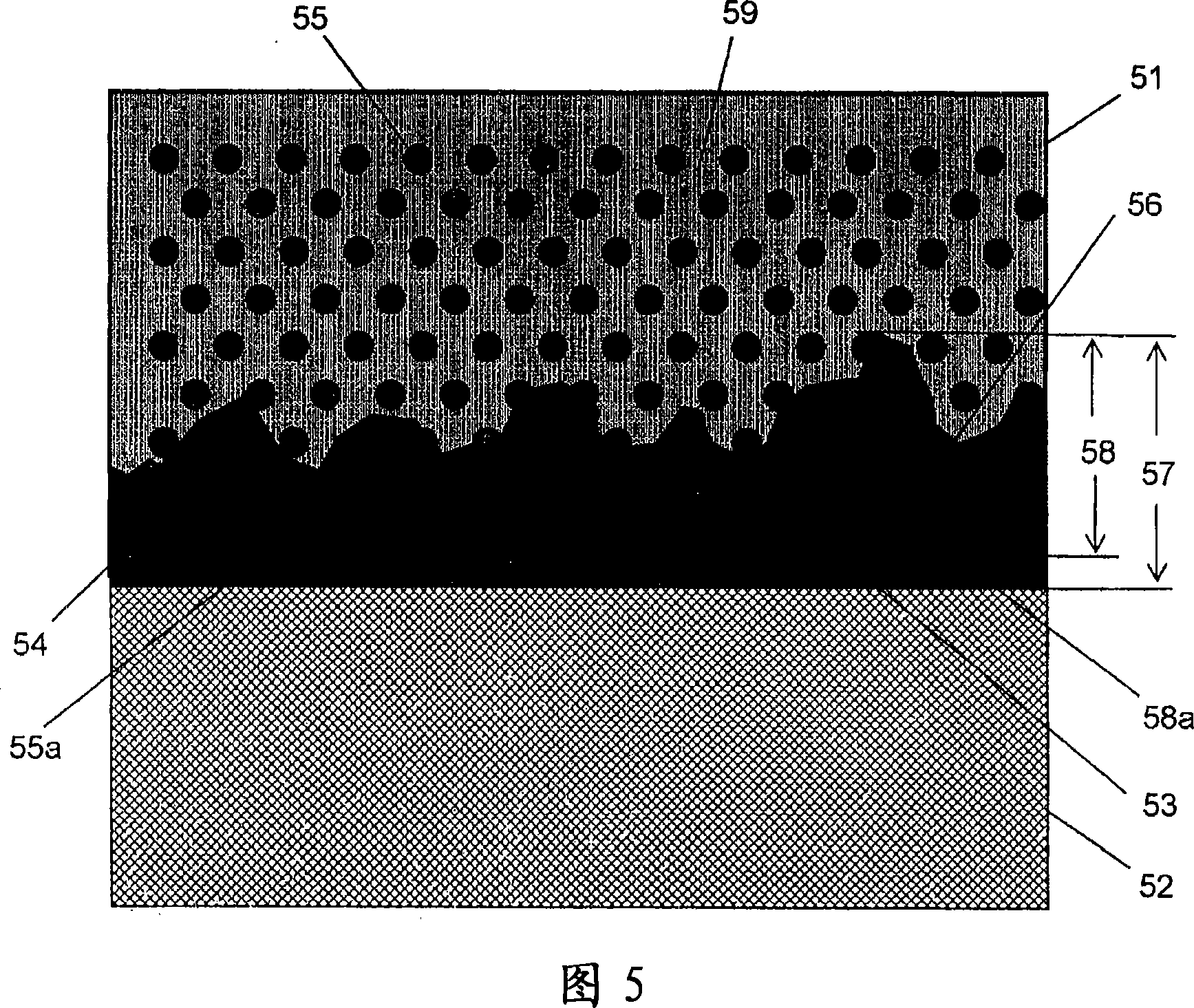

[0214] A prepreg formed by impregnating epoxy resin (thermosetting resin) into unidirectionally arranged carbon fiber groups (using Toray Co., Ltd. "TORAYCA (registered trademark)" prepreg P3052S-1 2, Toray ( Co., Ltd. "TORAYCA (registered trademark)" T700S, carbon fiber content: 67% by weight, fiber weight: 125g / m 2 ), cut out four prepreg sheets having a predetermined shape in a size of 350×350 mm. Using the above sheets, based on the fiber direction, stack them in the order of 0 degrees / 90 degrees / film (F-2) / core material / film (F-2) / 90 degrees / 0 degrees / film (F-1), Prepare the stack. As a core material, "EFCELL (registered trademark)" RC2010 (independently expanded polypropylene, thickness 1 mm, specific gravity 0.48) manufactured by Showa Denko Co., Ltd. was used.

[0215] Then, "Tedora (registered trademark)" film manufactured by Toray DuPont Co., Ltd. was arranged as a release film on the upper and lower sides of the laminate, placed on a flat plate for press molding m...

Embodiment 2

[0220] The aforementioned "EFCELL" RC2010 was cut into thin slices with a fixed thickness of 0.8 mm and used as the core material (I). The sandwich structure (III) was formed by curing the epoxy resin by applying a surface pressure of 1 MPa at 130° C. for 30 minutes. According to the same method as in Example 1, a sandwich structure (III) and an integrated molded body were prepared.

[0221] The sandwich structure serving as the top plate had a thickness of 1.3 mm and a flexural modulus of 35 GPa. The bonding strength between the core material (I) and the fiber-reinforced material (II) was 2 MPa, and it was confirmed that the joint interface above had the same impregnation structure as in Example 1, and the maximum impregnation length 18 was 15 μm.

[0222] The weight of the obtained integrated molded body was 136 g, and it was confirmed that it was a shell molded body excellent in lightness and rigidity. When the adhesive strength of the integral molded body was measured, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com