Hot rolling martensite steel plate with tensile strength higher than 1000Mpa and its production method

A technology of tensile strength and manufacturing method, which is applied in the field of hot-rolled ultra-high-strength martensitic steel plate and its manufacturing, can solve the problems of low steel plate strength level, increased process cost, high cost, etc., and achieves simple and easy hot-rolled process, The effect of low alloy cost and economical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The following are specific descriptions of Examples 1-11 of the present invention.

[0058] The concrete chemical composition (Wt%) of example 1-11 sees Table 1:

[0059] Table 1

[0060] make up

[0061] The concrete process parameter of example 1-11 is shown in Table 2:

[0062] Table 2

[0063]

[0064]

[0065] The mechanical properties of examples 1-11 are shown in Table 3.

[0066] table 3

[0067]

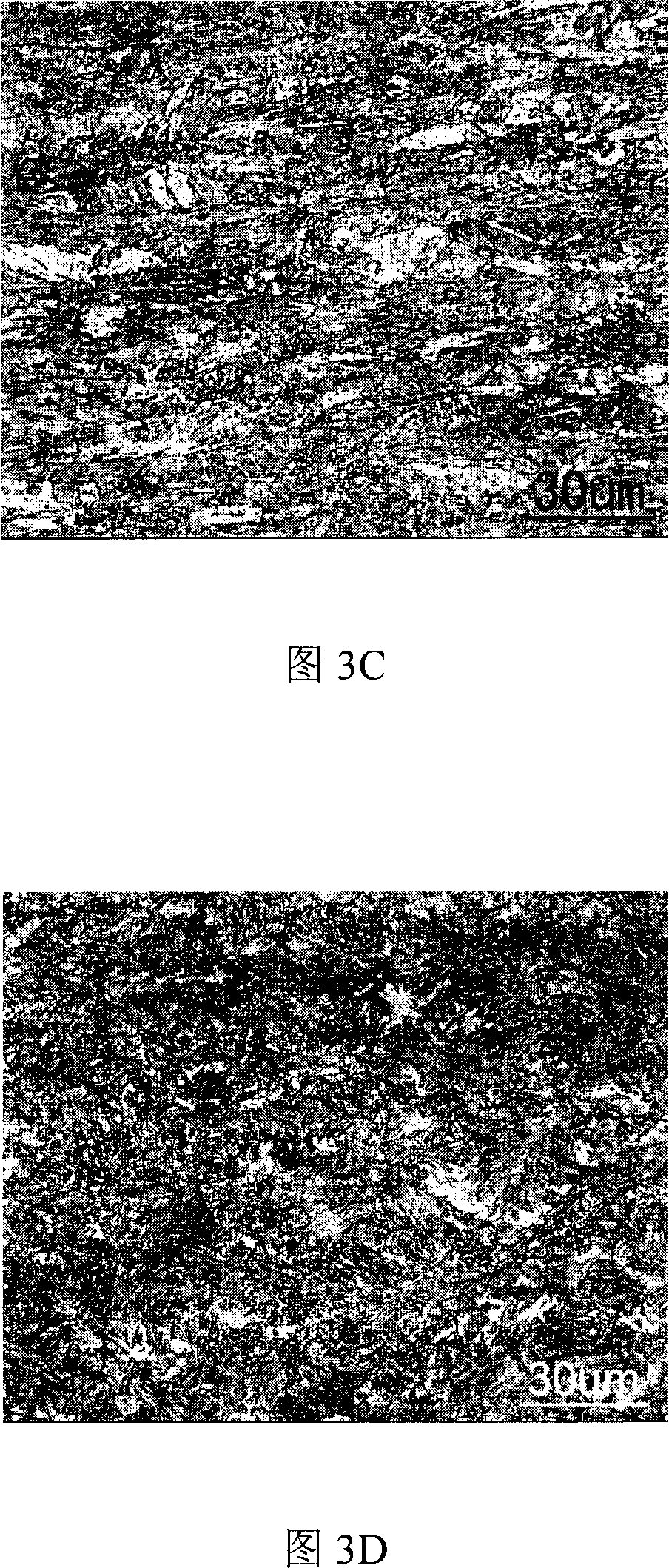

[0068] It can be seen from Table 3 that the longitudinal yield strength of 11 examples is greater than 750MPa, the tensile strength is between 1000MPa and 1100MPa, and the elongation is A 80 Greater than or equal to 7%, the vertical and horizontal cold bending d=4t (bend center diameter=4×steel plate thickness) are all qualified, reaching the requirement of tensile strength 1000MPa hot-rolled ultra-high-strength martensitic steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com