A method for preparing the small crystal grain NaY molecular screen

A molecular sieve and small-grain technology, which is applied in the directions of crystalline aluminosilicate zeolite, fajhedral crystalline aluminosilicate zeolite, etc., can solve the problems of easy volatilization, environmental pollution, low framework silicon and aluminum, etc., and achieves low cost and simple operation. Convenient, flexible modulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Directing agent preparation: get 100ml water glass (Changling Refinery Chemical Plant Catalyst Factory product, specific gravity 1.26, SiO 2 content 250g / L, modulus 3.25) into a beaker, add 54ml sodium metaaluminate solution (Changling Refinery Chemical Plant catalyst factory product, specific gravity 1.33, Al 2 o 3 Content 41g / L, Na 2 O content 297g / L), after mixing evenly, aging at room temperature for 24 hours, the desired directing agent can be obtained.

[0033] Preparation of silica-alumina gel: 220g of directing agent, 215ml of aluminum sulfate solution (product of Changling Oil Refinery and Chemical Plant Catalyst Factory, specific gravity 1.28, Al 2 o 3 Content 89.7g / L) and 170ml low sodium metaaluminate solution (Changling Oil Refinery Chemical Plant Catalyst Factory product, specific gravity 1.23, Al 2 o 3 Content 102g / L, Na 2 Add O content 155.1g / L) and 280ml of deionized water into 640ml of water glass (same specifications as above), and continue to s...

Embodiment 2

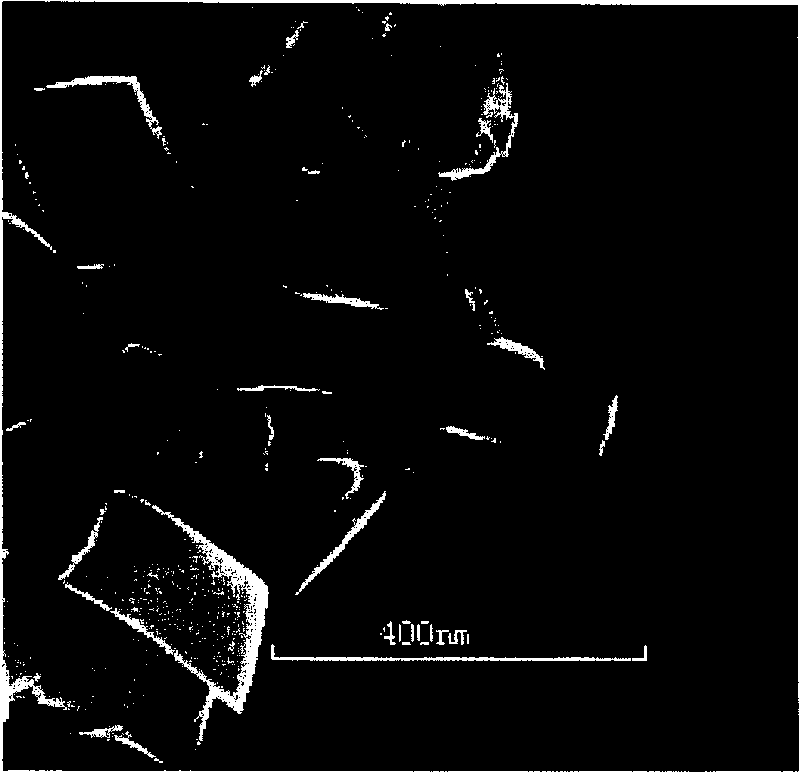

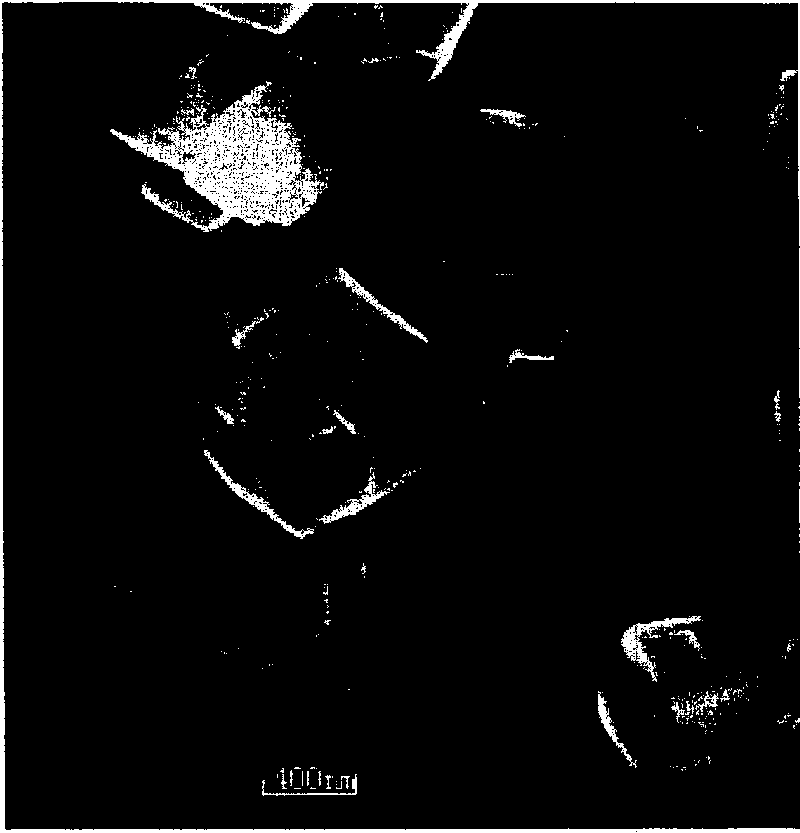

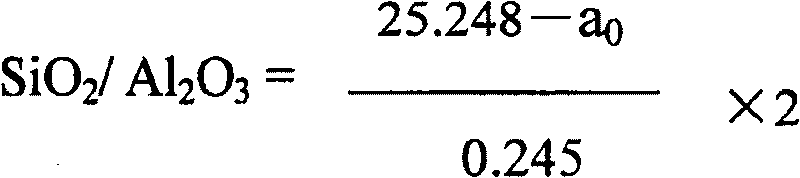

[0047] The preparation of the directing agent and the silica-alumina gel are the same as in Example 1. Aging 1000g of silica-alumina gel at 60°C for 30h, then adding 100g of diatomaceous earth to the gel, stirring vigorously for 3h, then statically crystallizing at 100°C for 30h, the product was filtered, washed, and dried to obtain NaY molecular sieve. The product is characterized by XRD, BET and SEM techniques, the results show that the crystallinity of NaY molecular sieve is 86.4%, SiO 2 / Al 2 o 3 is 5.33, and the total specific surface area measured by BET method is 670m 2 / g, the grain size is 100-300nm. The above-mentioned molecular sieves are exchanged for REY (RE 2 o 3 %w=15%), and after 800°C, 17h, 100% steam aging, the crystallization retention was 47.9% (compared with before hydrothermal aging).

Embodiment 3

[0049] The preparation of the directing agent and the silica-alumina gel are the same as in Example 1. Aging 1000g of silica-alumina gel at 65°C for 25h, then adding 300g of α-gibbsite to the gel, stirring vigorously for 3h, then statically crystallizing at 100°C for 30h. The product is filtered, washed and dried to obtain NaY molecular sieve. The product is characterized by XRD, BET and SEM technology, the results show that the crystallinity of NaY molecular sieve is 78%, SiO 2 / Al 2 o 3 is 5.23; the specific surface area is 595m 2 / g, the grain size is 200-300nm. The above-mentioned molecular sieves are exchanged for REY (RE 2 o 3 %W=15%), and after 800°C, 17h, 100% steam aging, the crystallization retention was 48.7% (compared with before hydrothermal aging).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com