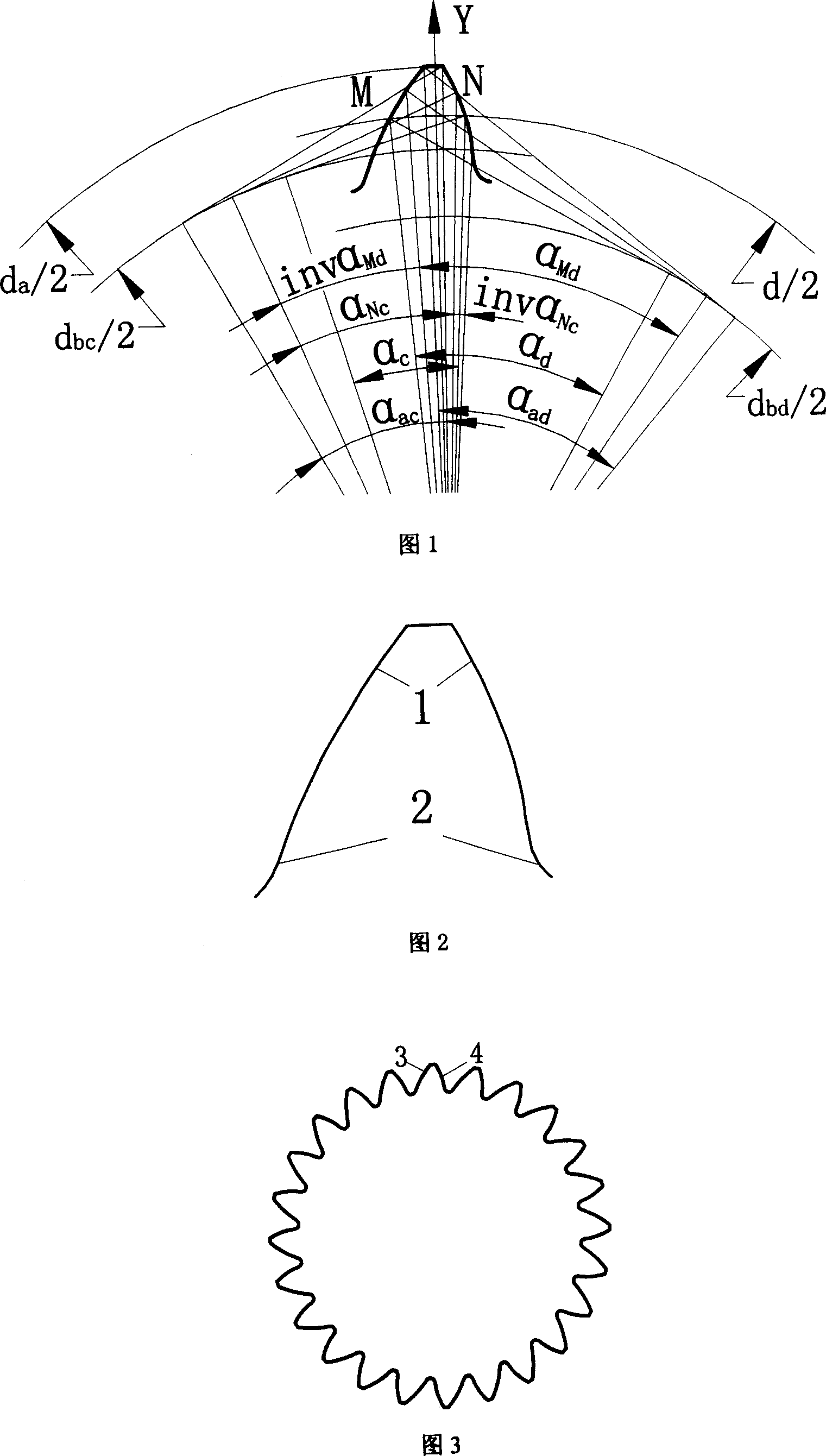

Processing method of asymmetric gear with two pressure angles

A processing method and double pressure angle technology, applied in the field of gears, can solve problems such as easy broken teeth and reduced coincidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] After loading the CAXA wire cutting software, input the involute equation and transition curve equation of the working tooth side and the non-working tooth side of the asymmetrical gear into the formula bar in the formula curve of the drawing tool bar, and the overall coordinate system adopts the Cartesian coordinate system. Angles are in radians. Enter the ranges of the four arguments into the From and To fields by calculation. The ranges of the four parameters are: α gd ≤α Md ≤α ad , α gc ≤α Nc ≤α ac , α d ≤α dx ≤π / 2,α c ≤α cx ≤π / 2, the precision is 0.02. After drawing these several curves in CAXA, the starting point of the involute of the working tooth side and the non-working tooth side does not coincide with the starting point of the transition curve, and the order of magnitude of the error value is 10 -5 ~10 -3 , the smaller the accuracy is, the smaller the error range is, here it is necessary to fuse the two starting points. Then input the equation o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com