ZSM-5 molecular sieve modified catalyst and its preparation method and application

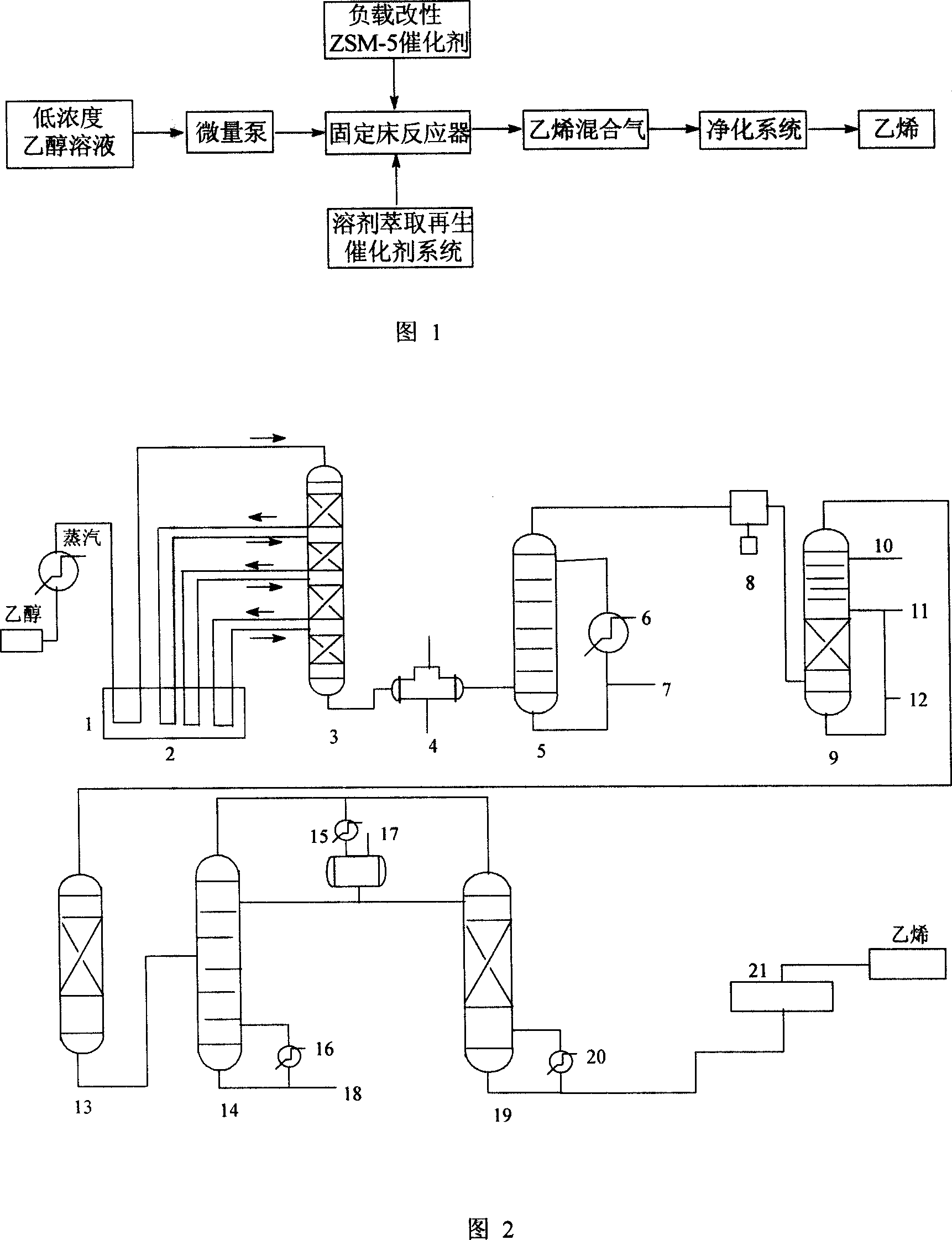

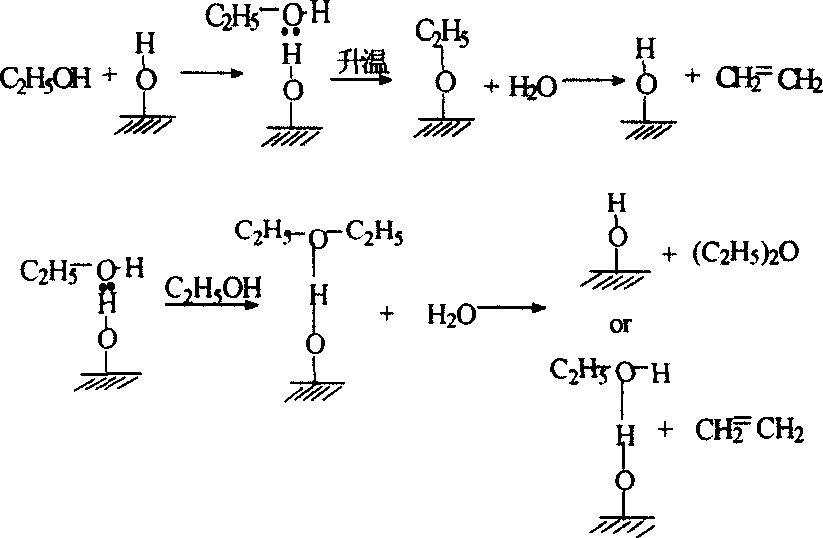

A ZSM-5, molecular sieve technology, used in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of difficulty in obtaining high-selectivity catalysts, high concentration of dilute ethanol solutions, and uneven molecular sieve crystal forms. The problem is that the catalytic activity does not decrease, the ethylene selectivity and yield are high, and the activity is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 750 grams of water glass, 71.6 grams of aluminum sulfate octadecahydrate are substrates (wherein SiO 2 / Al 2 o 3 =30,H 2 O / SiO 2 =34,Na 2 O / Al 2 o 3 =9), 32.9 grams of 98% concentrated sulfuric acid, add 1390 grams of water, stir in the stainless steel autoclave of 5 liters of volume after being stirred for 10 minutes, add 62.5 grams of ethylamine (65% weight concentration) again, rear sealing, 170 It was crystallized at ℃ for 60 hours, and then the crystallized product was filtered out, washed with water several times and then dried. It was identified as ZSM-5 molecular sieve by phase identification.

[0032] d(A) 11.4 10.3 3.9 3.8 3.7

[0033] I / I 0 strong strong strong strong strong

[0034] The silicon-aluminum ratio of the obtained molecular sieve is 29.6 in bulk and 17.0 in the surface, with a difference of 42.6%; the crystal size is 1-3 microns. The synthesized sodium form ZSM-5 was exchanged into ammonium form by conventional methods.

[0035] Ge...

Embodiment 2

[0037] 750 grams of water glass, 57.5 grams of aluminum sulfate octadecahydrate are matrix (wherein SiO 2 / Al 2 o 3 =50,H 2 O / SiO 2 =33, Na 2 O / Al 2 o 3 =12), 31 grams of 98% concentrated sulfuric acid, add 1375 grams of water and mix uniformly, then 7.5 grams of ZSM-5 crystal powder synthesized by the method of the present invention is added to the above-mentioned system, and after stirring for 10 minutes, transfer to a 5 liter volume container In the stainless steel autoclave, add 37.5 grams of ethylamine (65% by weight), then seal the can, crystallize at 170°C for 80 hours, then filter out the crystallized product, wash it with water for several times, and dry it. ZSM-5 molecular sieve. The synthesized sodium-form ZSM-5 was exchanged into ammonium form by conventional methods, and the silicon-aluminum ratio of bulk was 36.5, and the surface silicon-aluminum ratio was 24.7, with a difference of 32.3%; the crystal size was 2-5 microns.

[0038] Get 80 grams of ammoniu...

Embodiment 3

[0040] 750 grams of water glass and 98.3 grams of aluminum sulfate octadecahydrate are substrates (wherein SiO 2 / Al 2 o 3 =100,H 2 O / SiO 2 =34,Na 2 O / Al 2 o 3 =15), 34.9 grams of 98% concentrated sulfuric acid, add 1402 grams of water and mix uniformly, then 8.0 grams of ZSM-5 crystal powder synthesized by the method of the present invention is added to the above-mentioned system, and after stirring for 10 minutes, transfer to 5 liters of volume In the stainless steel autoclave, add 72.5 grams of ethylamine (65% weight concentration), then seal the can, crystallize at 170°C for 60 hours, then filter out the crystallized product, wash it with water for several times, and then dry it. It is a ZSM-5 molecular sieve, and the silicon-aluminum ratio of the obtained molecular sieve is 58.6 in bulk and 38.1 in the surface, with a difference of 35%; the crystal size is 3-6 microns. The synthesized sodium form ZSM-5 was exchanged into ammonium form by conventional methods.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com