Fiber enhanced composite material of shape memory, and application

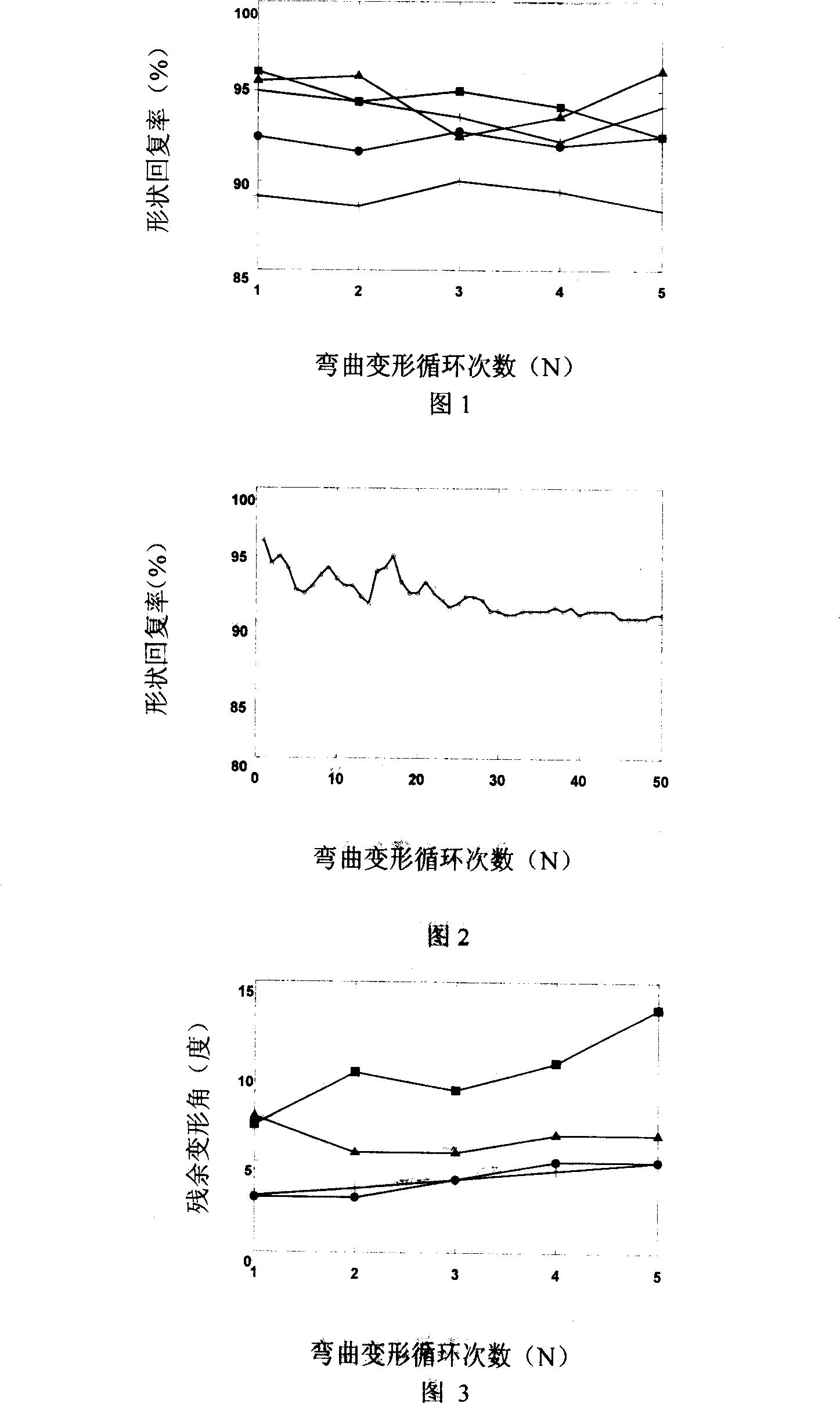

A fiber-reinforced, composite material technology, used in medical science, dolls, instruments, etc., can solve the problems of poor mechanical properties such as stiffness and strength, poor motion stability and reliability, and poor shape retention ability, and achieve good motion stability. , can recover the effect of large strain and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] Embodiment 1: The fiber-reinforced shape-memory composite material of this embodiment is composed of a shape-memory polymer material and a fiber-reinforced phase material; the volume percentage content of each component material of the fiber-reinforced shape-memory composite material is: shape-memory polymer material 20 ~95%, fiber reinforced phase material 5~80%.

specific Embodiment approach 2

[0026] Embodiment 2: The volume percentage content of each component material of the fiber-reinforced shape-memory composite material in this embodiment is: shape-memory polymer material 40-90%, fiber-reinforced phase material 10-60%.

specific Embodiment approach 3

[0027] Embodiment 3: The volume percentage content of each component material of the fiber-reinforced shape-memory composite material in this embodiment is: shape-memory polymer material 50-80%, fiber-reinforced phase material 20-50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com