Catalyst of load type bimetallic cyaniding complex, preparation method and application

A double metal cyanide and complex technology, applied in the field of preparation of supported double metal cyanide complex catalysts, can solve the problem of low catalytic activity, achieve the effect of increased catalyst activity and be conducive to industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

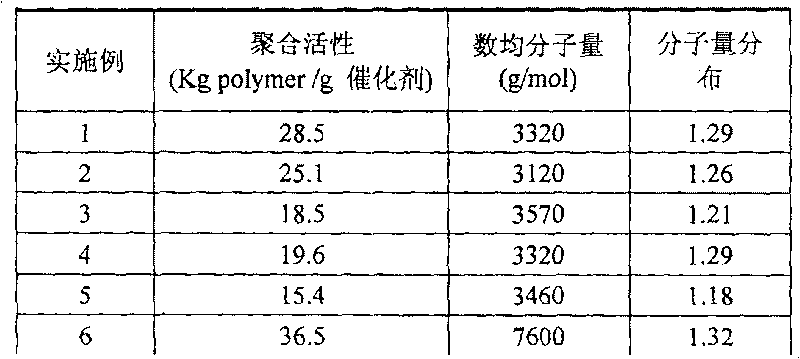

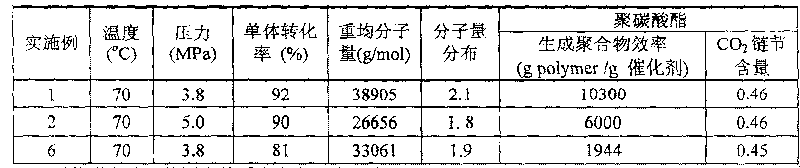

Examples

Embodiment 1

[0028] 9g ZnCl 2 Dissolve in a mixed solution of deionized water (40mL) and tert-butanol (20mL), and stir until uniform and transparent. 0.76g K 3 [Co(CN) 6 ] was dissolved in 7 mL deionized water, and the K 3 [Co(CN) 6 ] Aqueous solution is dripped into above-mentioned ZnCl within 10 minutes 2 / water / tert-butanol solution, while adding 3.5 g of ethyl orthosilicate, and stirred at 30°C for 24 hours. Then suction filter, wash the filter cake three times with 200 mL of the mixed solution of water and tert-butanol, and then use pure tert-butanol to slurry at 30 ° C for 12 hours, after suction filtration, place it in a 60 ° C vacuum oven and dry to constant weight to obtain White solid 2.19g.

Embodiment 2

[0030] 10g ZnCl 2 Dissolve in a mixed solution of deionized water (40mL) and tert-butanol (25mL), and stir until uniform and transparent. 0.76g K 3 [Co(CN) 6 ] was dissolved in 7 mL deionized water, and K 3 [Co(CN) 6 ] aqueous solution in 10 minutes drop / into the above ZnCl 2 / water / tert-butanol solution, while adding 4.5 g of ethyl titanate, and stirred at 30°C for 24 hours. Then suction filter, wash the filter cake three times with 200 mL of the mixed solution of water and tert-butanol, and then use pure tert-butanol to slurry at 30 ° C for 12 hours, after suction filtration, place it in a 60 ° C vacuum oven and dry to constant weight to obtain White solid 2.56g.

Embodiment 3

[0032] 15g ZnCl 2 Dissolve in a mixed solution of deionized water (40mL) and tert-butanol (30mL), and stir until uniform and transparent. 1.0g K 2 Ni(CN) 4 Dissolve in 10mL deionized water, at 30°C this K 2 Ni(CN) 4 The aqueous solution was added dropwise to the above ZnCl within 10 minutes 2 / water / tert-butanol solution, while adding 5.0 g of ethyl orthosilicate, and stirred at 30°C for 24 hours. Then suction filter, wash the filter cake three times with 200 mL of the mixed solution of water and tert-butanol, and then use pure tert-butanol to slurry at 30 ° C for 12 hours, after suction filtration, place it in a 60 ° C vacuum oven and dry to constant weight to obtain SiO 2 The supported Ni-Zn bimetallic catalyst is 3.39g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com