Greasy of containing glycerin ester type conjugate linolic acid and protuction process thereof

A conjugated linoleic acid and glyceride-based technology, which is applied in the production of fatty acids and chemical modification of fatty acids, can solve problems such as low smoke point, no research reports, and poor flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

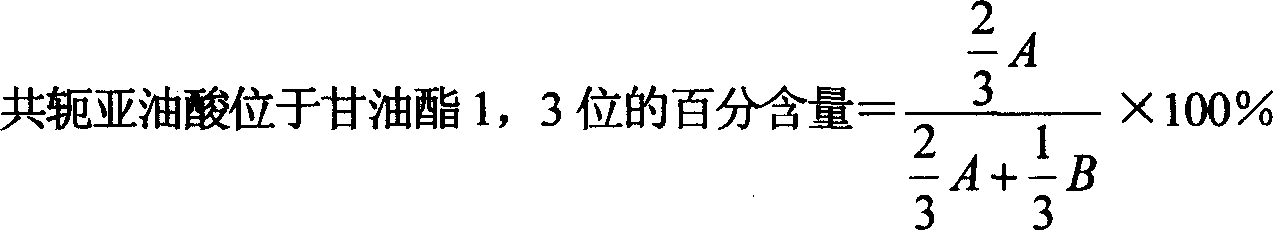

Method used

Image

Examples

Embodiment 1

[0026] Get the fatty acid ethyl ester that comprises 70% conjugated linoleic acid and soybean oil mixture 10kg and place in the reactor, control the weight ratio of conjugated linoleic acid ethyl ester (in pure matter) and soybean oil to be 1: 60, in two 5% immobilized lipase LipozymeTLIM (product of Novozymes Company) was added to the mixture, and stirred at 200 rpm and reacted at 35° C. for 3 hours. The reactant was molecularly distilled at 150°C to remove fatty acid ethyl ester and free fatty acid to obtain oil 1.

Embodiment 2

[0028] Get the fatty acid ethyl ester that comprises 70% conjugated linoleic acid and soybean oil mixture 10kg and place in the reactor, control the weight ratio of conjugated linoleic acid ethyl ester (in pure matter) and soybean oil to be 20: 60, combine two The mixture of the former passed through a packed bed reactor equipped with immobilized lipase Lipozyme TLIM, the reaction temperature was 70°C, and the residence time of the oil in the reactor was 0.5 hours. The reactant was molecularly distilled at 150°C to remove fatty acid ethyl ester and free fatty acid etc. to obtain oil 2.

Embodiment 3

[0030] Get the fatty acid ethyl ester that comprises 70% conjugated linoleic acid and rapeseed oil mixture 10kg and place in the reactor, control the weight ratio of conjugated linoleic acid ethyl ester (in pure matter) and soybean oil to be 6: 60, will The mixture of the two passed through a packed bed reactor equipped with immobilized lipase Lipozyme TLIM, the reaction temperature was 70°C, and the residence time of the oil in the reactor was 1 hour. The reactant is distilled under reduced pressure at 230°C, and high-purity nitrogen is constantly blown in during the distillation process to remove fatty acid ethyl ester and free fatty acid to obtain oil 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com