Preparation method of high retention heavy calcium carbonate

A technology of heavy calcium carbonate and heavy calcium carbonate powder, applied in the direction of calcium carbonate/strontium/barium, inorganic compound addition, etc., can solve the problems of difficulty in increasing production cost, low retention rate, high abrasion of heavy calcium carbonate, and achieves Conducive to environmental protection, improve retention rate, reduce the effect of wood pulp consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

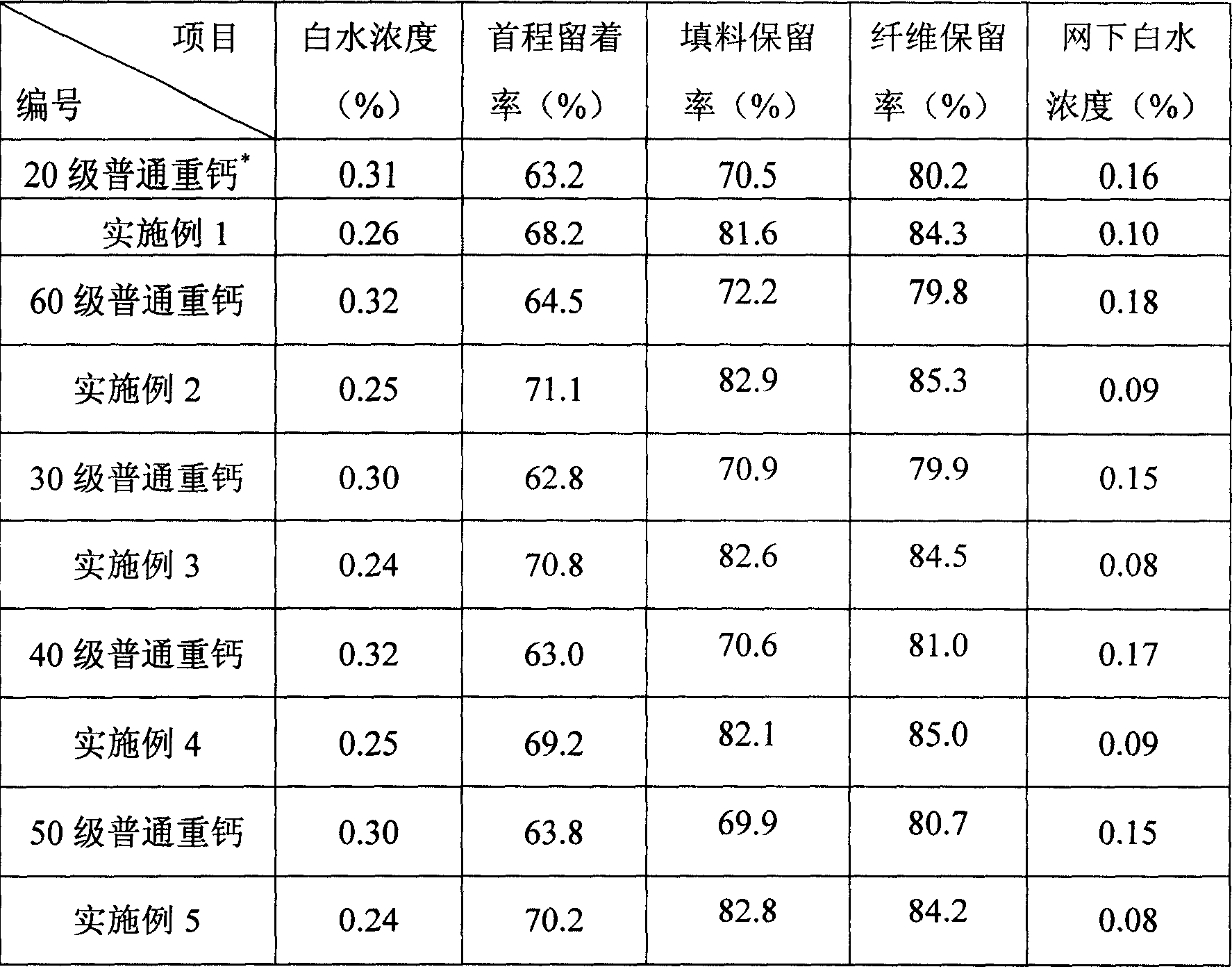

Examples

Embodiment 1

[0017] Add 4 tons of 100 mesh heavy calcium carbonate powder to 7.4 tons of deionized water, stir to make a slurry, and add 8kg of sodium polyacrylate dispersant to the slurry, and stir. Slurry is sent into a 300 liters of peeling machines with pump then, heavy calcium carbonate is ground with peeling machine, makes heavy calcium carbonate slurry, wherein is less than 2 μm content 20%.

[0018] Add 8kg dodecyl dimethyl benzyl ammonium chloride then in making heavy calcium carbonate slurry, stir 2 hours, then add 20kg hexadecyl dimethyl benzyl in heavy calcium carbonate slurry ammonium chloride, and stirred for 1.5 hours to obtain a high-retention heavy calcium slurry, which can be directly used as paper-making filler.

Embodiment 2

[0020] Add 4 tons of 400-mesh heavy calcium carbonate powder to 3 tons of deionized water, stir to make a slurry, and add 20kg of sodium polyacrylate dispersant to the slurry, and fully stir to make the slurry obtain good fluidity. Then the slurry is sent into a 300-liter sand mill with a pump, and the heavy calcium carbonate is ground with the sand mill to obtain a heavy calcium carbonate slurry, wherein the content of less than 2 μm is 60%. Then add 40kg dodecyl dimethyl benzyl ammonium bromide in the heavy calcium carbonate slurry, stir 1 hour, then add 80kg octadecyl dimethyl benzyl in the heavy calcium carbonate slurry ammonium chloride, and stirred for 2 hours to obtain a high-retention heavy calcium slurry, which was filtered to make 5.6 tons of filter cakes with a solid content of 70%, which can be directly used as papermaking fillers.

Embodiment 3

[0022] Add 4 tons of 600-mesh heavy calcium carbonate powder to 1.3 tons of deionized water, stir to make a slurry, and add 80kg of sodium polyacrylate dispersant to the slurry, and fully stir to make the slurry obtain good fluidity. Slurry is sent into an 80 liters of peeling machine with pump then, heavy calcium carbonate is ground with peeling machine, makes heavy calcium carbonate slurry, wherein is less than 2 μm content 30%. Add 80kg dodecyl dimethyl benzyl ammonium chloride then in the heavy calcium carbonate slurry, stir 1.5 hours, then add 200kg octadecyl dimethyl benzyl in the heavy calcium carbonate slurry Ammonium chloride was stirred for 2.5 hours to obtain a high-retention heavy calcium slurry. The slurry is filtered to make 6.9 tons of filter cake with a solid content of 60%, dried at 105°C for 3 hours, and then pulverized by a hammer mill to obtain 4.1 tons of high-retained heavy calcium powder, which can be used as papermaking filler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com