Lumber slicer

A chip splitter and log technology, applied in the manufacture of thin wood chips, wood processing equipment, manufacturing tools, etc., can solve the problems of unprocessable logs, poor working environment, etc., achieve wood saving, high production efficiency, and reduce labor The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

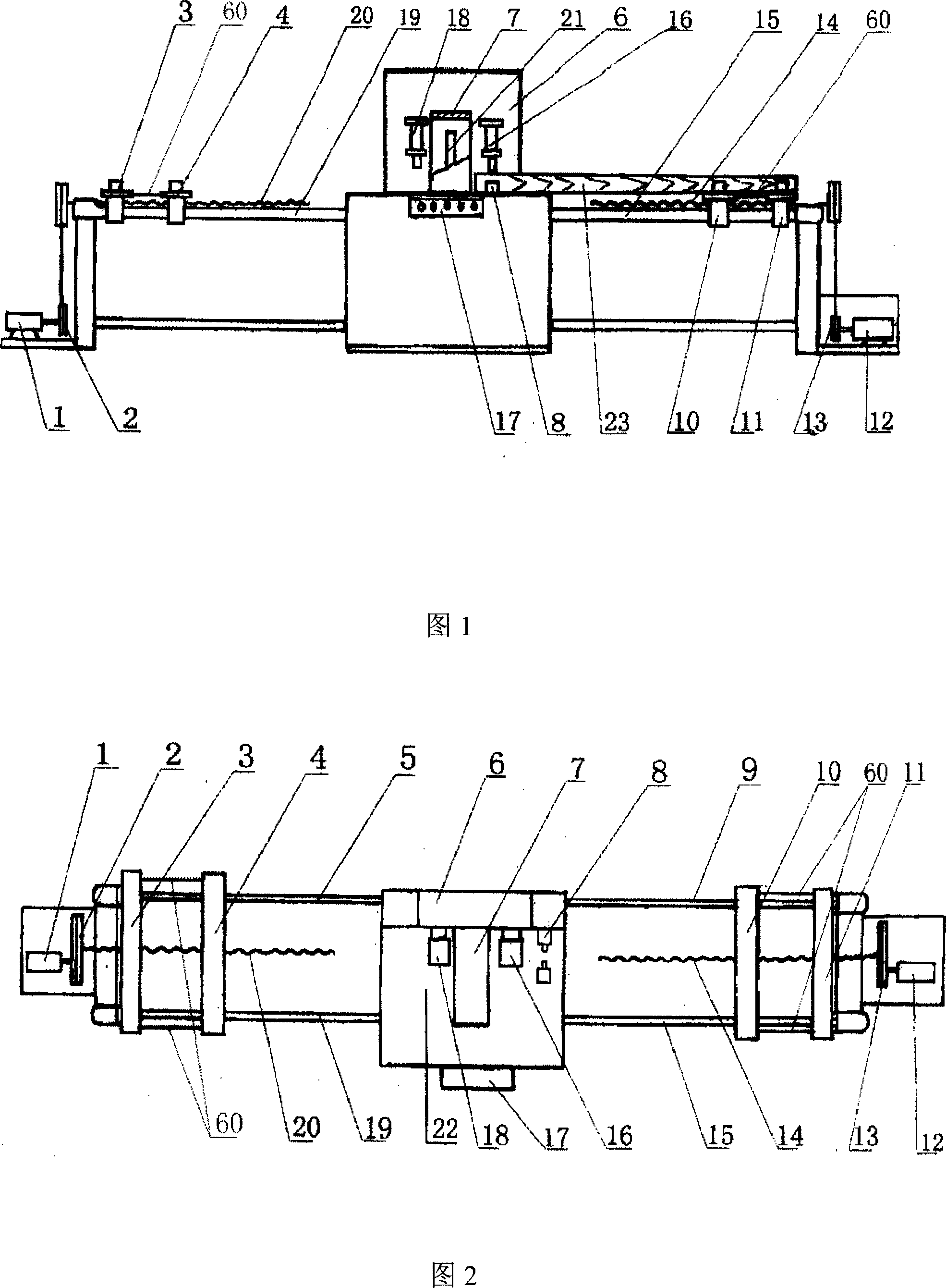

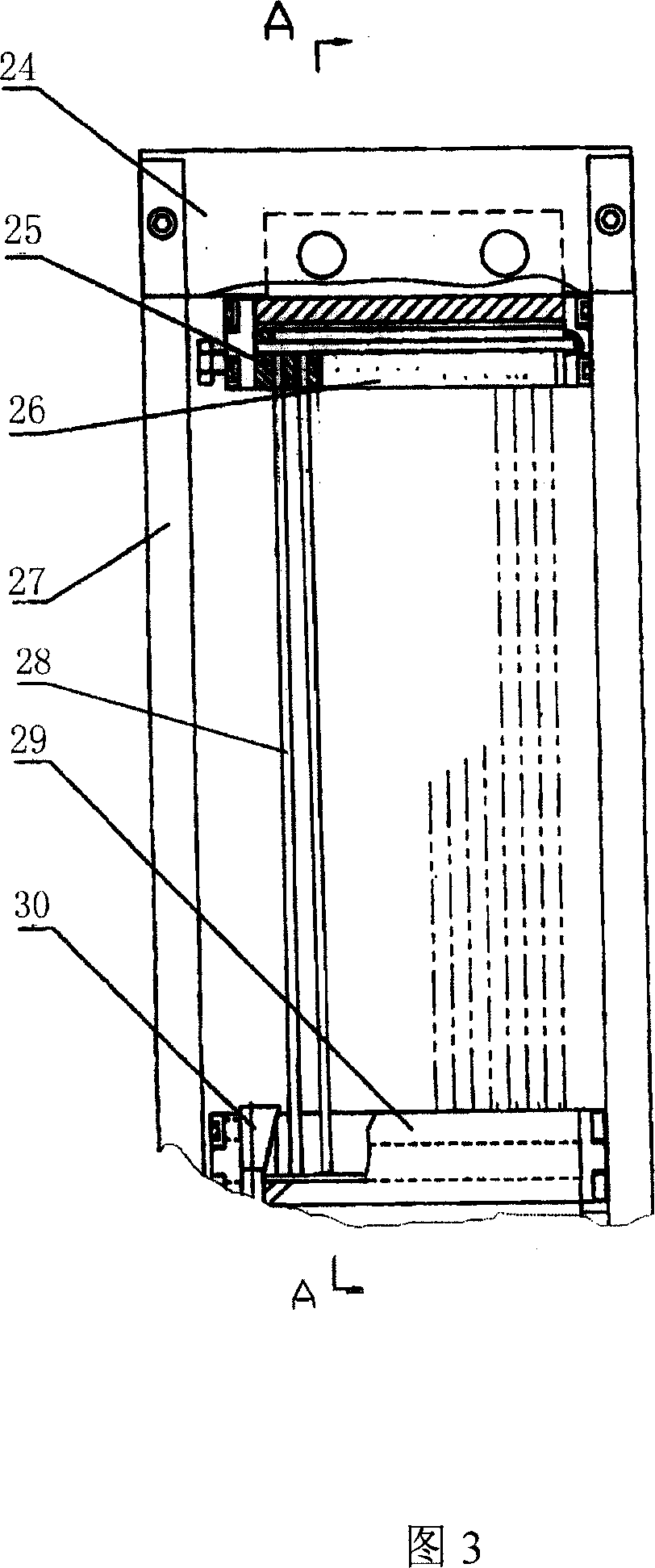

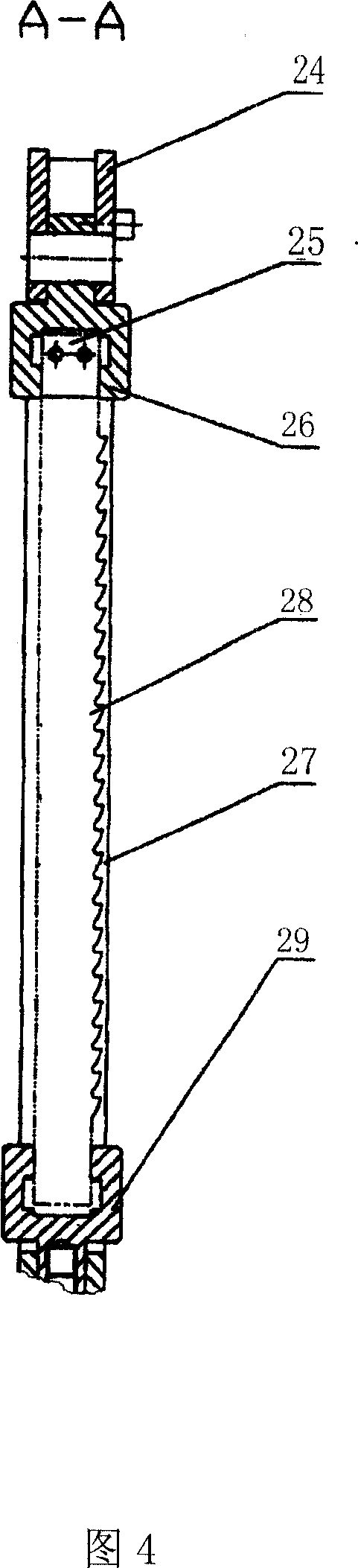

[0026] As shown in Fig. 1 and Fig. 2, the round log frame sawing machine that can directly process the round wood into slices includes a frame saw in the middle of the working platform 22 of the frame, the power mechanism, and the working platform 22 of the frame 6. The opening through which the mechanism 21 passes, there is a wood support mechanism 18 above the two sides of the frame saw mechanism 21, and the two sides of the working platform 22 are fixedly connected with a feed mechanism that pushes the log to the frame saw at a uniform speed and a feed mechanism that pushes the log to the frame saw at a uniform speed. Pull off the catch mechanism of the frame saw. There is a log centering mechanism 8 in front of the feeding of the frame saw mechanism 21, and the frame 6 above the working platform 22 has a rectangular frame 7, and the frame saw mechanism 21 reciprocates up and down in the rectangular frame 7, and the log 23 The axis is perpendicular to the frame saw mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com