Animal feed additives based on fermentation broth and production process thereof by granulation

A technology for animal feed and production method, which is applied to the molding or processing of animal feed, animal feed, animal feed, etc., can solve problems such as increasing difficulty, and achieve the effects of stabilizing the content of lysine, increasing the content, and improving the effect of moisture absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

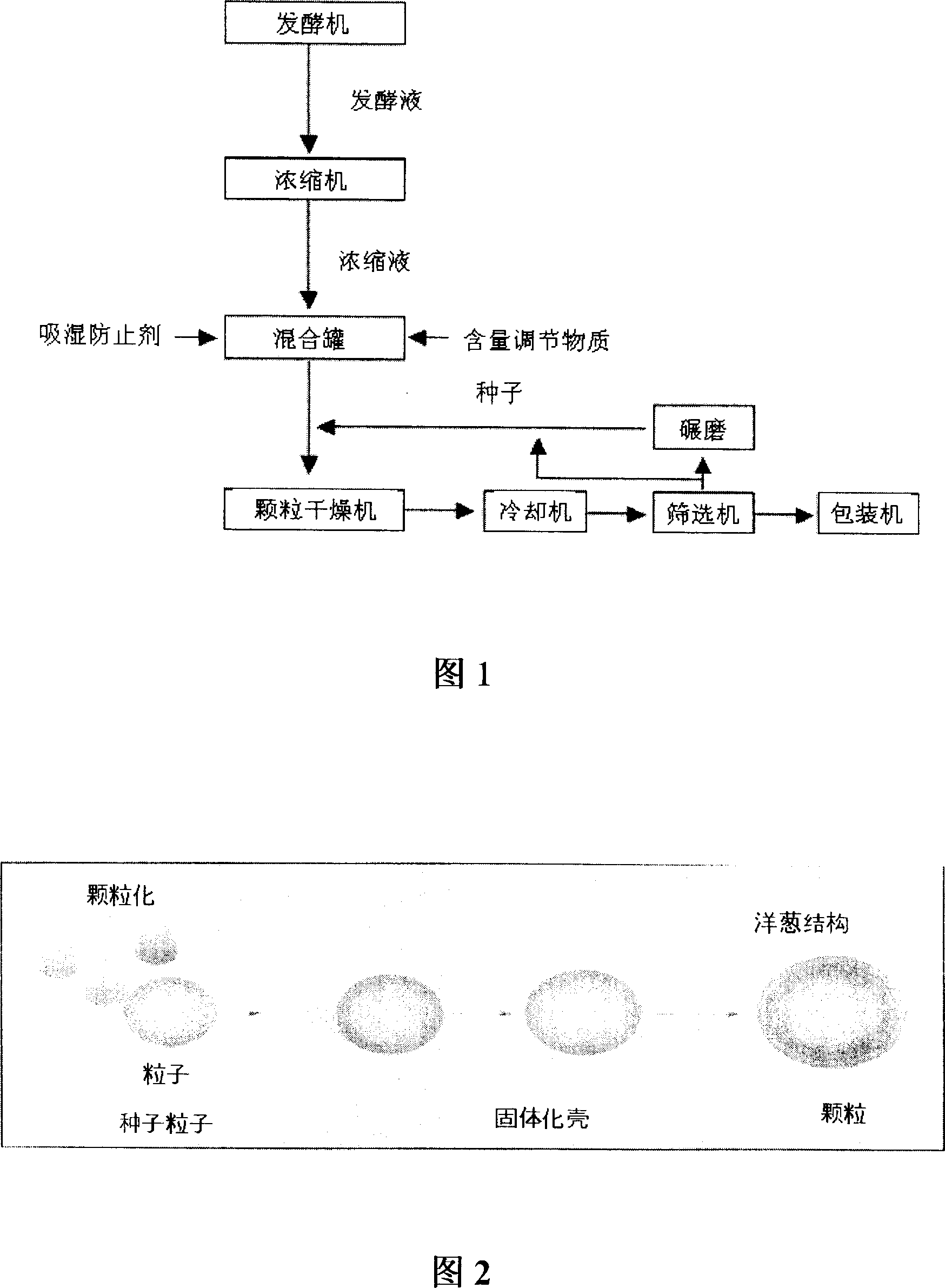

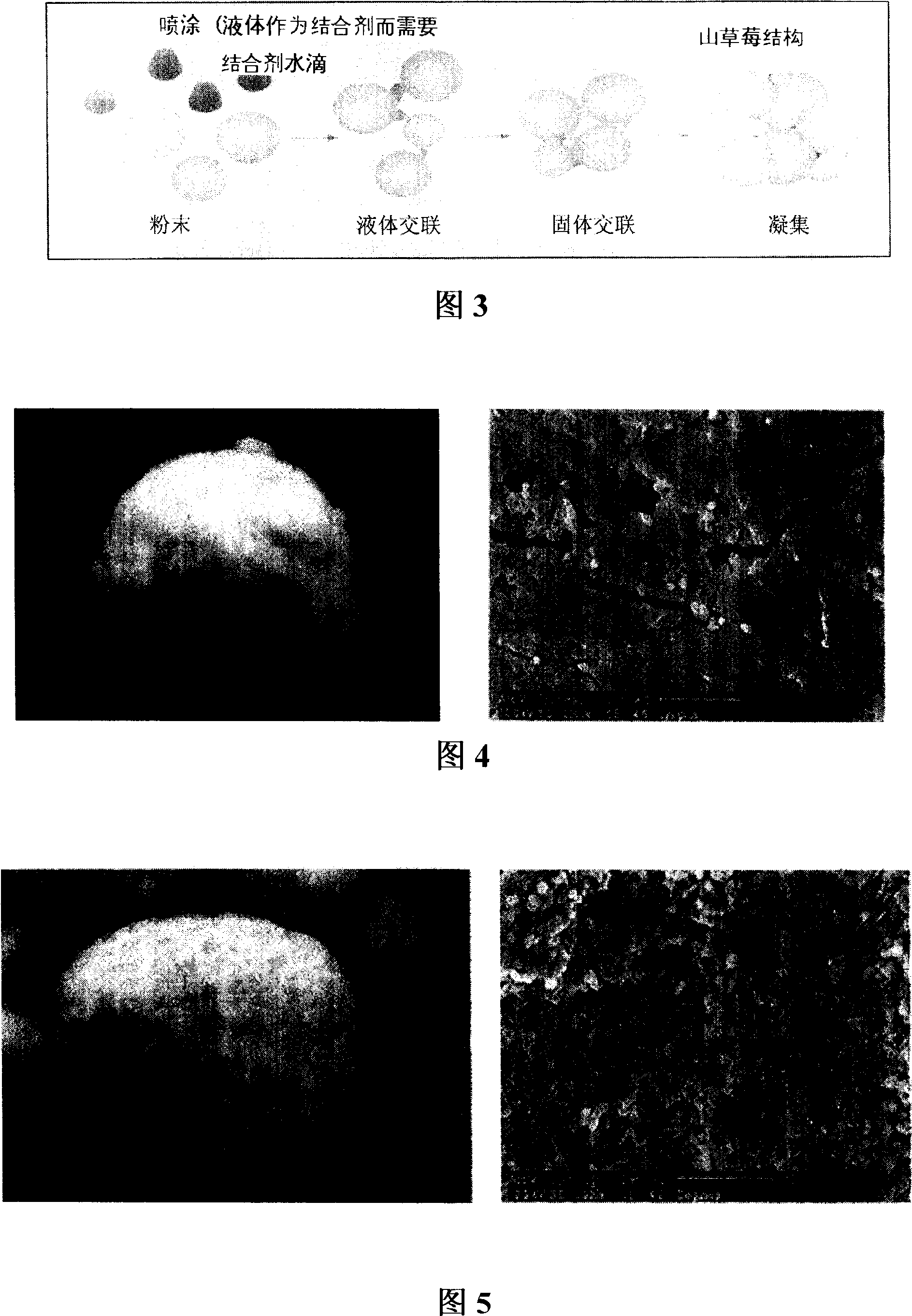

Method used

Image

Examples

Embodiment 1

[0066] [Example 1] directly form granule by fermented liquid

[0067] In this example, Corynebacterium glutamicum CJM107 (KCCM-10227) was prepared with 1 l of process water as a standard, and contained 50 g of raw sugar, 10 g of peptone, 10 g of yeast extract, 5 g of urea, and KH 2 PO 4 4g,K 2 HPO 4 8g, MgSO 4 ·7H 2 O 0.5g, biotin 100μg, thiamine HCl 1,000μg of the medium 18l, at the culture temperature of 35 ℃, culture medium pH 6 ~ 8 range for 98 hours to complete the lysine fermentation process. The lysine content in the fermentation broth was 18%.

[0068] After concentrating the filtrate of the fermented broth to a level of 55.2 wt% of the total solid content by concentrating under reduced pressure, the pH is adjusted to 3.5-3.6. The pH adjustment was performed with sulfuric acid, and after the pH adjustment, the concentrated solution was left in a 60° C. environment for 2.5 hours.

[0069] After the gDNA decomposition process, the concentrated liquid was injected...

Embodiment 2

[0071] [Example 2] Adding free lysine in the fermentation broth to adjust the content

[0072] The fermented liquid (with a lysine content of 14.5%) produced through the fermentation process under the same conditions as in Example 1 was concentrated to a total solid content of 51.5 wt%. 8 g of free lysine (manufactured by CJ Co., Ltd.) was added thereto, and after mixing in a mixing box, the same conditions as in Example 1 were used to prepare granules.

[0073] The finally obtained product has a lysine content of 68%, a protein content of 14%, a moisture content of 0.13%, and a surface density of 665.5kg / m 3 , Inorganic matter content 2.50%, 3% for particle size range of 0-500μm or less, 28% for particle size exceeding 500μm or less than 1000μm, 67% for particle size range of 1000μm-1300μm or less, and 2% for particle size exceeding 1300μm.

Embodiment 3

[0074] [Example 3] Add content regulator to adjust content in fermented liquid

[0075] The fermented liquid produced by fermentation under the same conditions as in Example 1 was used, and its lysine content was 20%, and the total solid content was 25.8%.

[0076] After the fermented liquid is concentrated, an excipient with a water content of 9.0% prepared by dissolving 0.22 kg of cornstarch in 0.5.L of water is added to the concentrated liquid as a content regulator, and mixed in a mixing box.

[0077] Concentrate the filtrate of the fermented broth to a solid content of 50.5 wt% by concentrating under reduced pressure, and then make granules under the same conditions as in Example 1.

[0078] In this example, the finally obtained product has a lysine content of 66%, a protein content of 14%, a moisture content of 0.24%, and a surface density of 682.5kg / m 3 , Inorganic matter content 1.88%, particle size range 0-500μm or less is 4%, more than 500μm and 1000μm is 29%, more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com