Core-shell structure zeolite multilevel ordered mesopore and micropore composite material and preparation method thereof

A composite material and shell structure technology, applied in the direction of crystalline aluminosilicate zeolites, chemical instruments and methods, molecular sieve catalysts, etc., to achieve the effect of product structure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

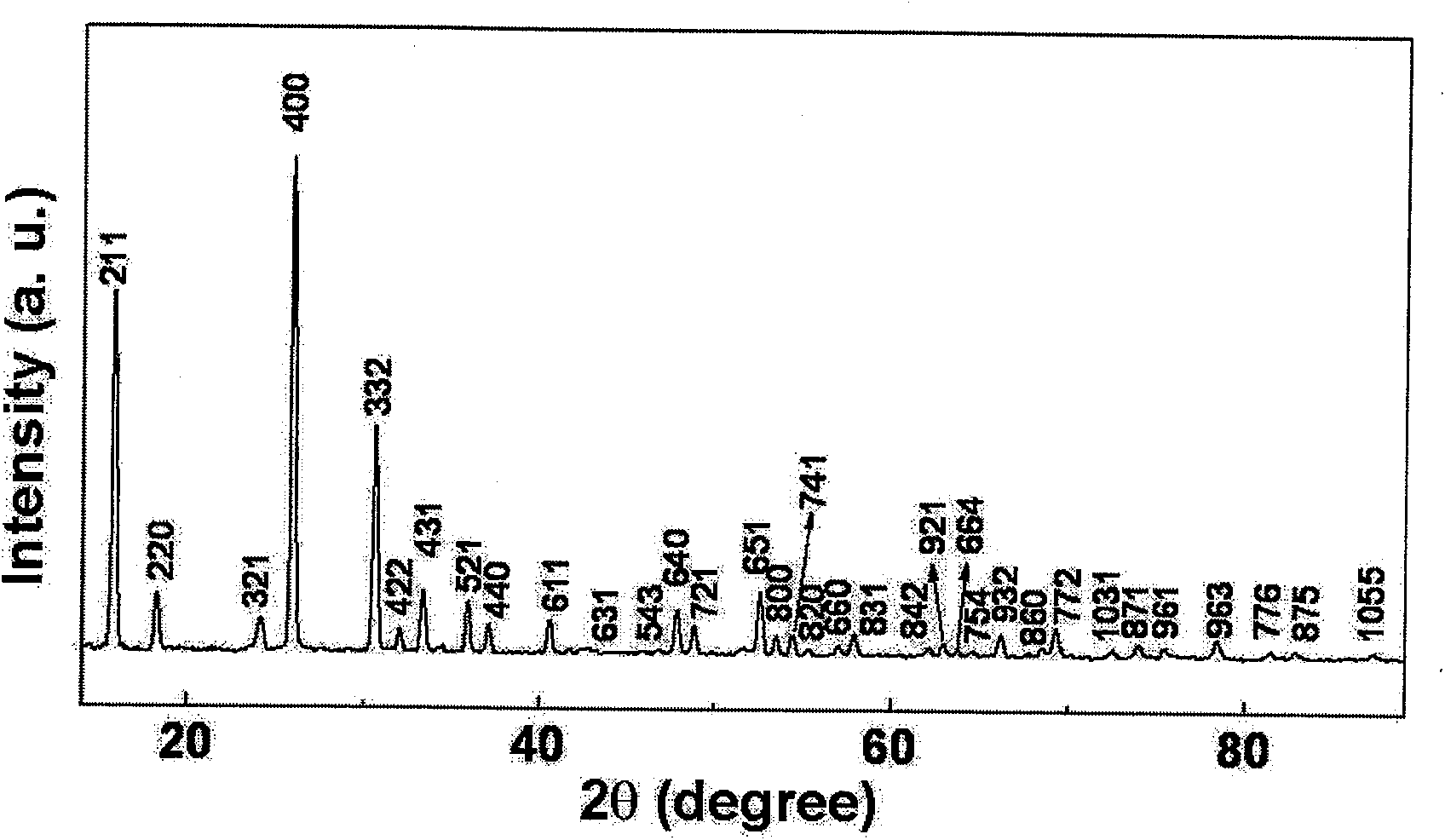

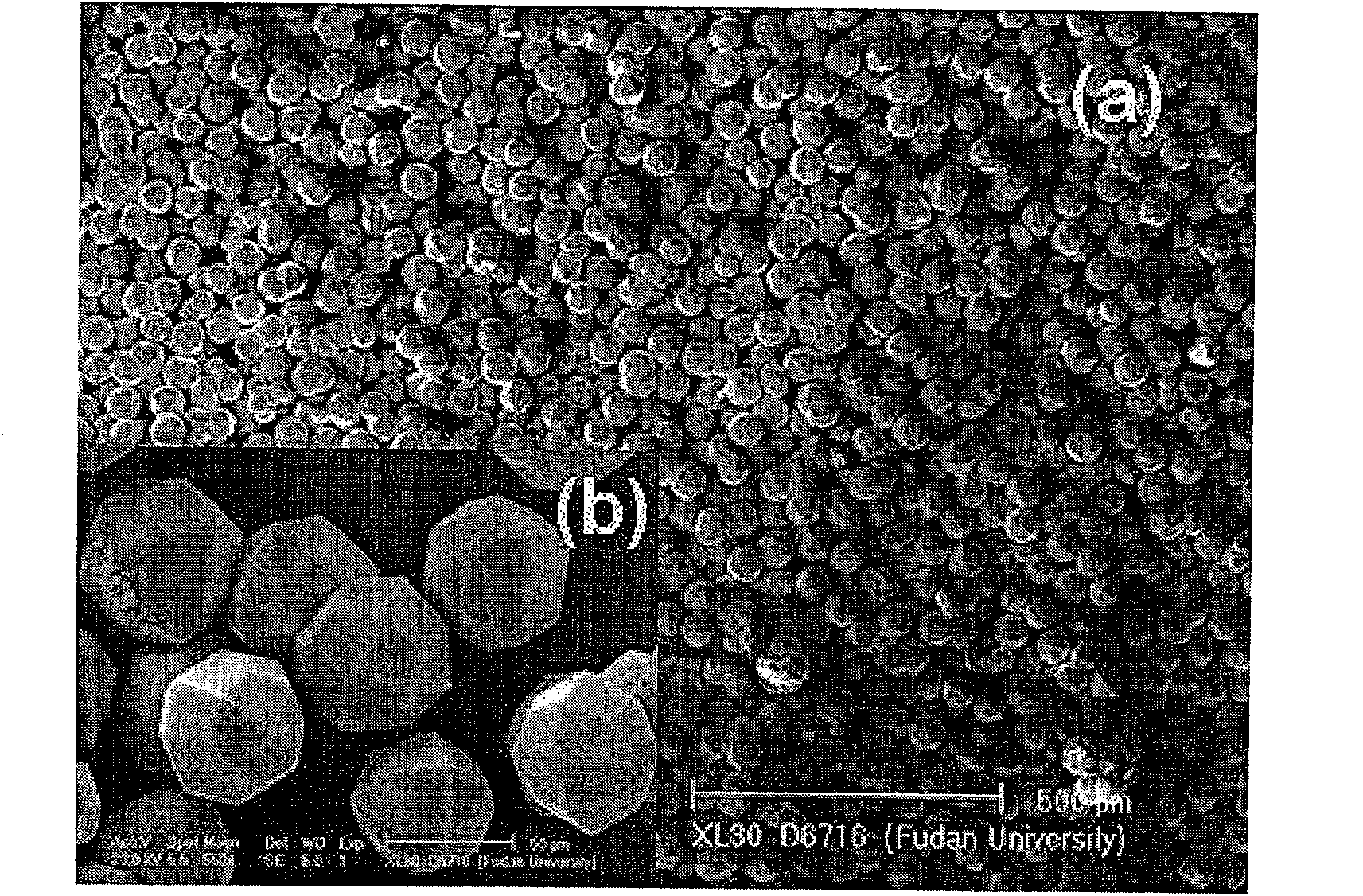

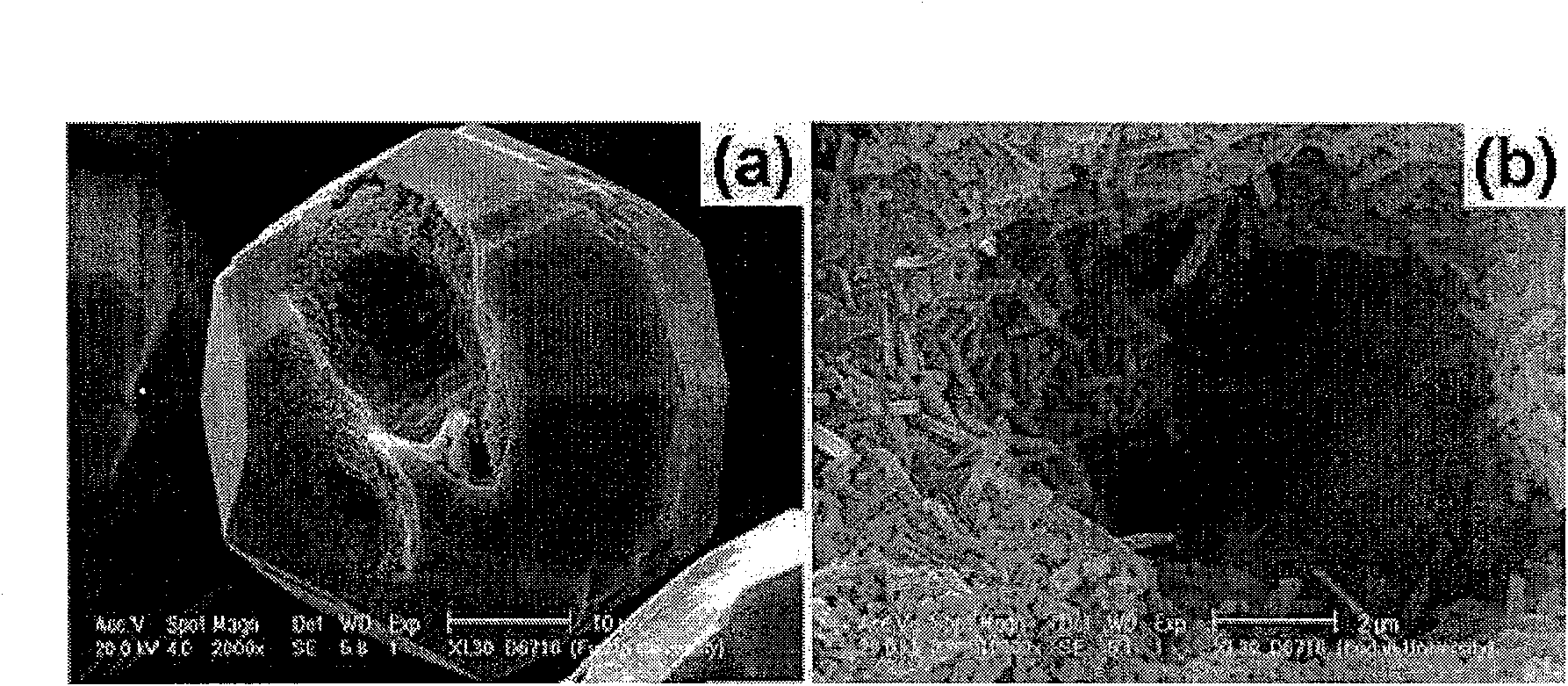

[0017] Example 1: Ni-Al alloy was gradually added to 90° C. sodium silicate aqueous solution and stirred for 2 hours to extract aluminum in the Ni-Al alloy. Then add ethylamine and concentrated sulfuric acid under vigorous stirring, and adjust the pH=9.6, the molar composition of the entire reaction solution is SiO 2 :Na 2 O:Ni:Al:C 2 h 5 NH 2 :H 2 SO 4 :H 2 O=1:1:0.22:0.48:1.26:0.63:19. After the reaction solution was evenly stirred, it was put into a reaction kettle, sealed, crystallized at 180°C for 8 days, suction filtered, washed with water until neutral, dried at room temperature, and then calcined at 550°C for 6 hours. The resulting product corresponds to Figure 1-4 characterization results.

Embodiment 2

[0018] Example 2: Gradually add Ni-Al alloy into sodium silicate aqueous solution at 100° C. and vigorously stir for 1 hour to extract aluminum in Ni-Al alloy. Then add ethylamine and concentrated sulfuric acid under vigorous stirring, and adjust the pH=10, the molar composition of the entire reaction solution is SiO 2 :Na 2 O:Ni:Al:C 2 h 5 NH 2 :H 2 SO 4 :4H 2 O=1:1:0.22:0.48:1.34:0.63:24. After the reaction solution was evenly stirred, it was put into a reaction kettle, sealed, crystallized at 200°C for 72 hours, filtered with suction, washed with water until neutral, dried at room temperature, and then calcined at 600°C for 3 hours. The resulting product corresponds to figure 1 , Figure 5 Characterization results of a.

Embodiment 3

[0019] Example 3: Ni-Al alloy was gradually added to 95° C. sodium silicate aqueous solution and vigorously stirred for 1.5 h to extract aluminum in the Ni-Al alloy. Then add ethylamine and concentrated sulfuric acid under vigorous stirring, and adjust the pH=9.8, the molar composition of the entire reaction solution is SiO 2 :Na 2 O:Ni:Al:C 2 h 5 NH 2 :H 2 SO 4 :H 2 O=1:1:0.22:0.48:1.30:0.63:22. After the reaction solution was evenly stirred, it was put into a reaction kettle, sealed, crystallized at 150°C for 14 days, filtered with suction, washed with water until neutral, dried at room temperature, and then calcined at 550°C for 6 hours. The resulting product corresponds to figure 1 , Figure 6 Characterization results of b.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com