SAW pressure sensor and method for fabricating the sensor part

A pressure sensor and sensor technology, used in the measurement of fluid pressure, fluid pressure measurement using acoustic methods, instruments, etc., can solve the problems of complex structure, unsuitable for accurate measurement and large-scale industrial production, low sensor measurement sensitivity, etc. The effect of large measurement range, simple structure and manufacturing process, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

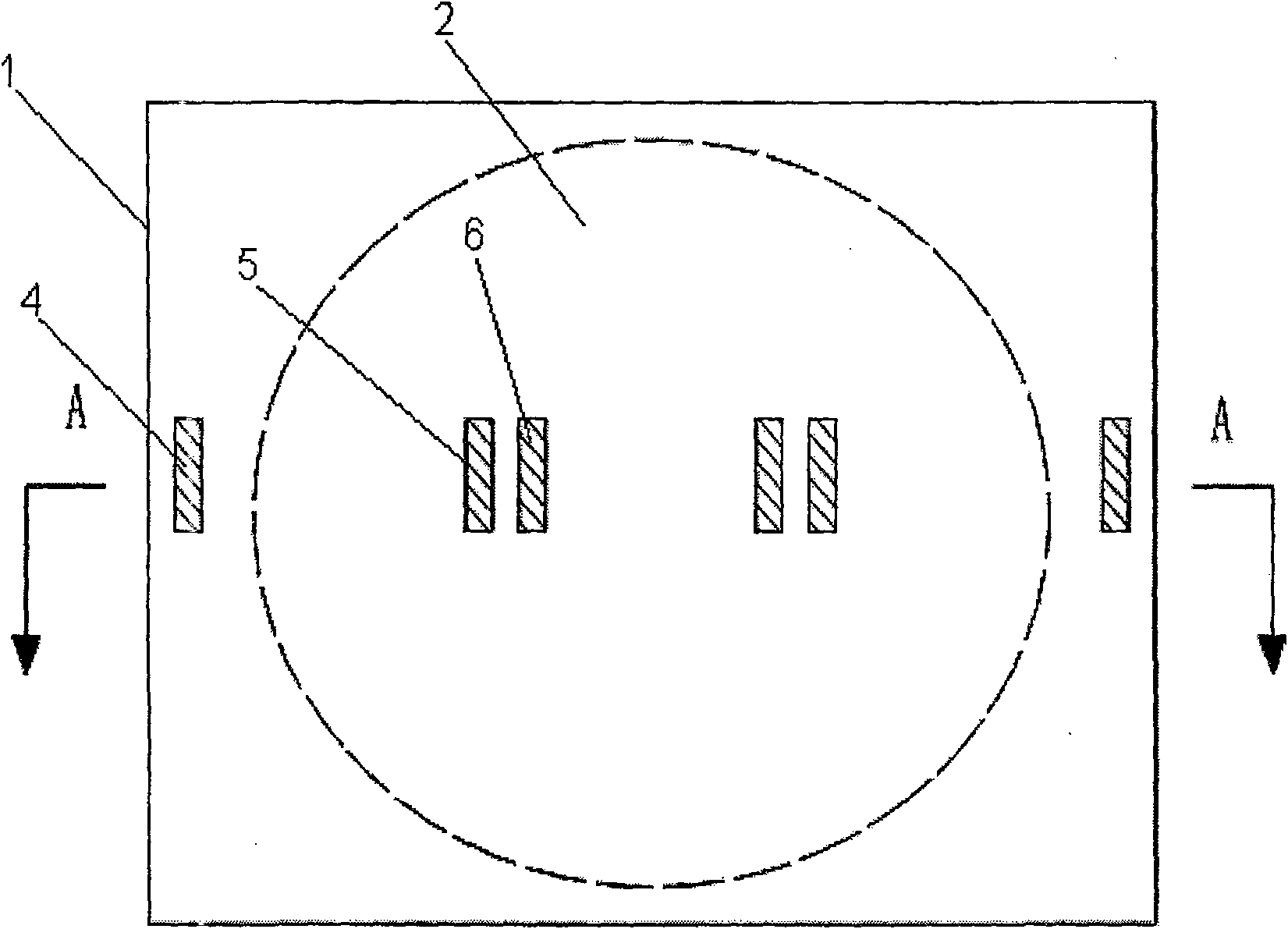

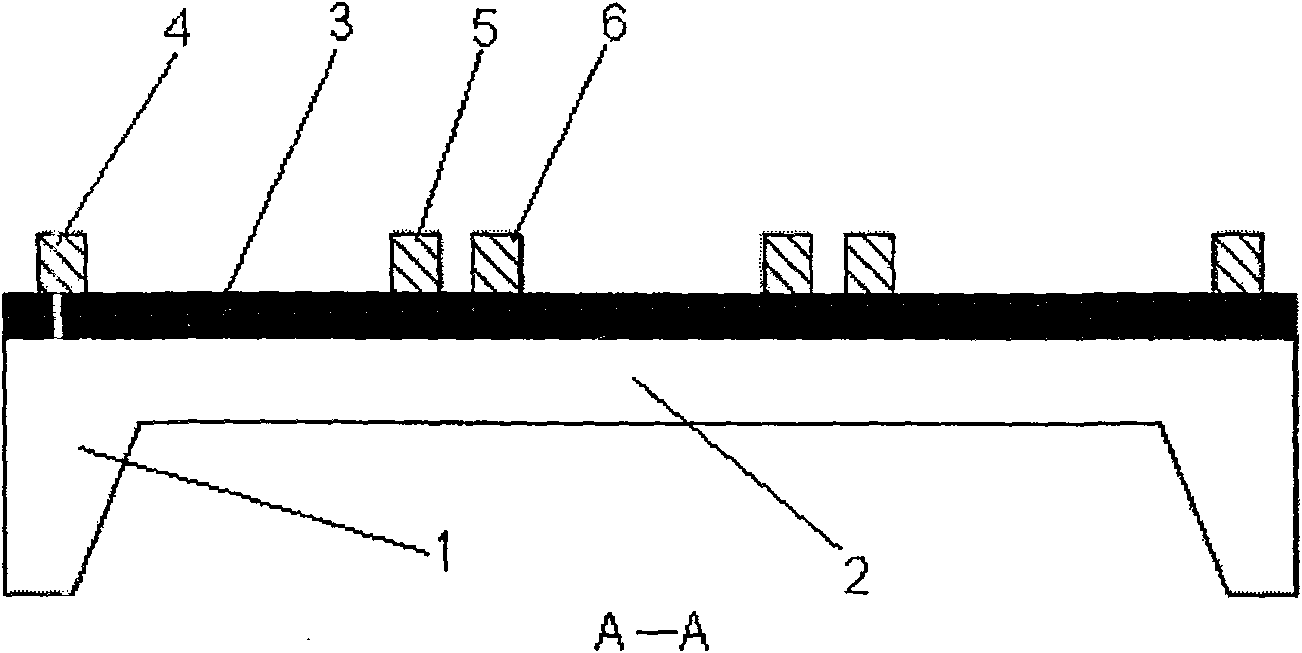

[0019] Such as figure 1 , figure 2 As shown, the present invention includes two parts: a sensor and a wireless readout circuit.

[0020] Such as figure 1 , image 3 As shown, the sensor part of the present invention includes a substrate 1 made of silicon material, and a circular cavity, namely a silicon cup, is etched out in the middle of the back of the substrate 1 . The thinned part on the substrate 1 forms a circular membrane 2 like this, and the thickness of the circular membrane 2 is at most 1 / 4 of the substrate 1 thickness, and this circular membrane 2 is the high deformation region of the substrate 1, and the substrate 1 and the rest are fixed ends. The front side of the substrate 1 is covered with a piezoelectric material film 3, and two groups of SAW elements are symmetrically arranged on the piezoelectric material film 3, and each grou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com