Method and equipment for cleaning photographic film

A technology for cleaning equipment and films, applied in cleaning methods and utensils, cleaning methods using gas flow, separation methods, etc., can solve the problems of increasing the amount and particle size of dust, uneven coating, short service life, etc. And the effect of convenient use, improved coating quality and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

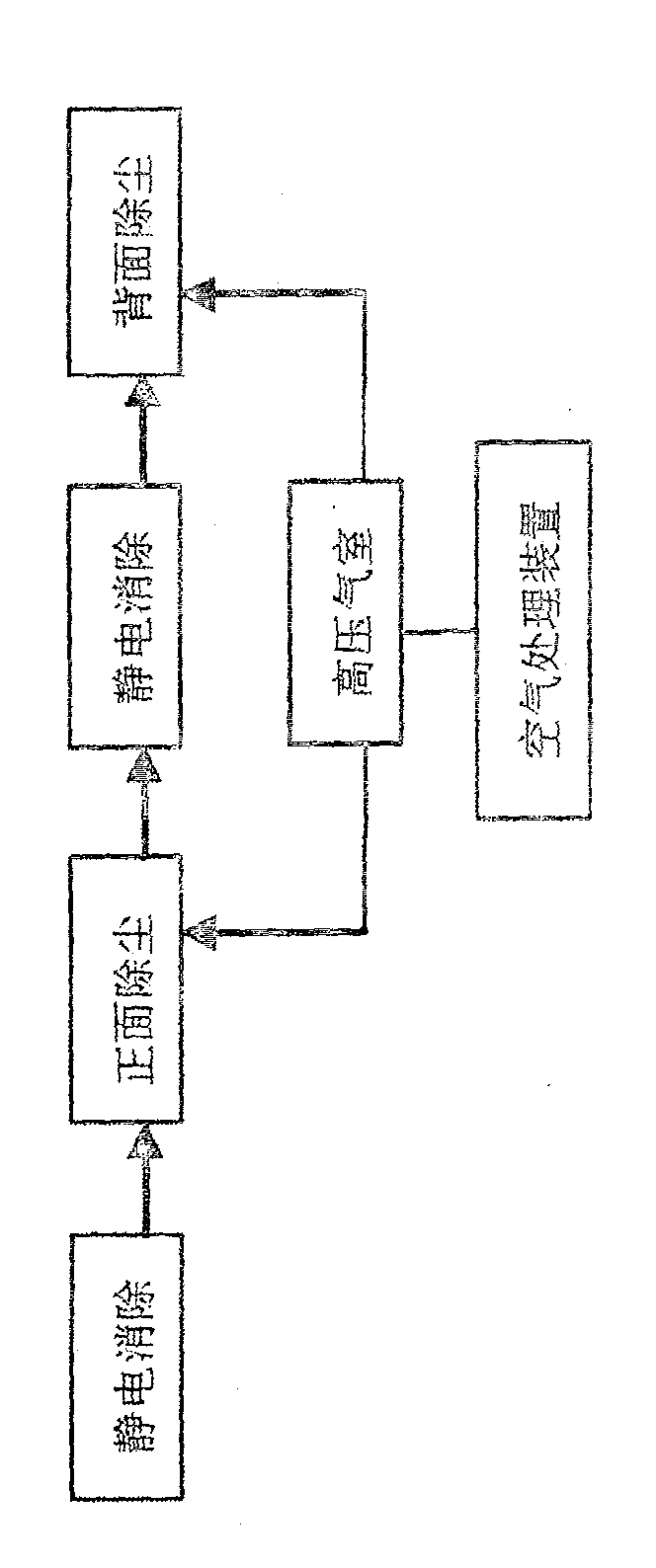

[0023] Such as figure 1 As shown, the film cleaning method in this preferred embodiment comprises the following steps:

[0024] (1) Eliminate static electricity on the front of the film base;

[0025] (2) Blow with high-pressure strong wind to eliminate the dust on the front of the film base, and filter the dusty air;

[0026] (3) Purify the filtered air to obtain clean air, which is then blown by strong wind again;

[0027] (4) Convert one side to eliminate static electricity on the back of the film base;

[0028] (5) Blow with high-pressure strong wind to eliminate the dust on the back of the film base, and filter the air with dust;

[0029] (6) Purify the filtered air to obtain clean air, which is then blown by strong wind again.

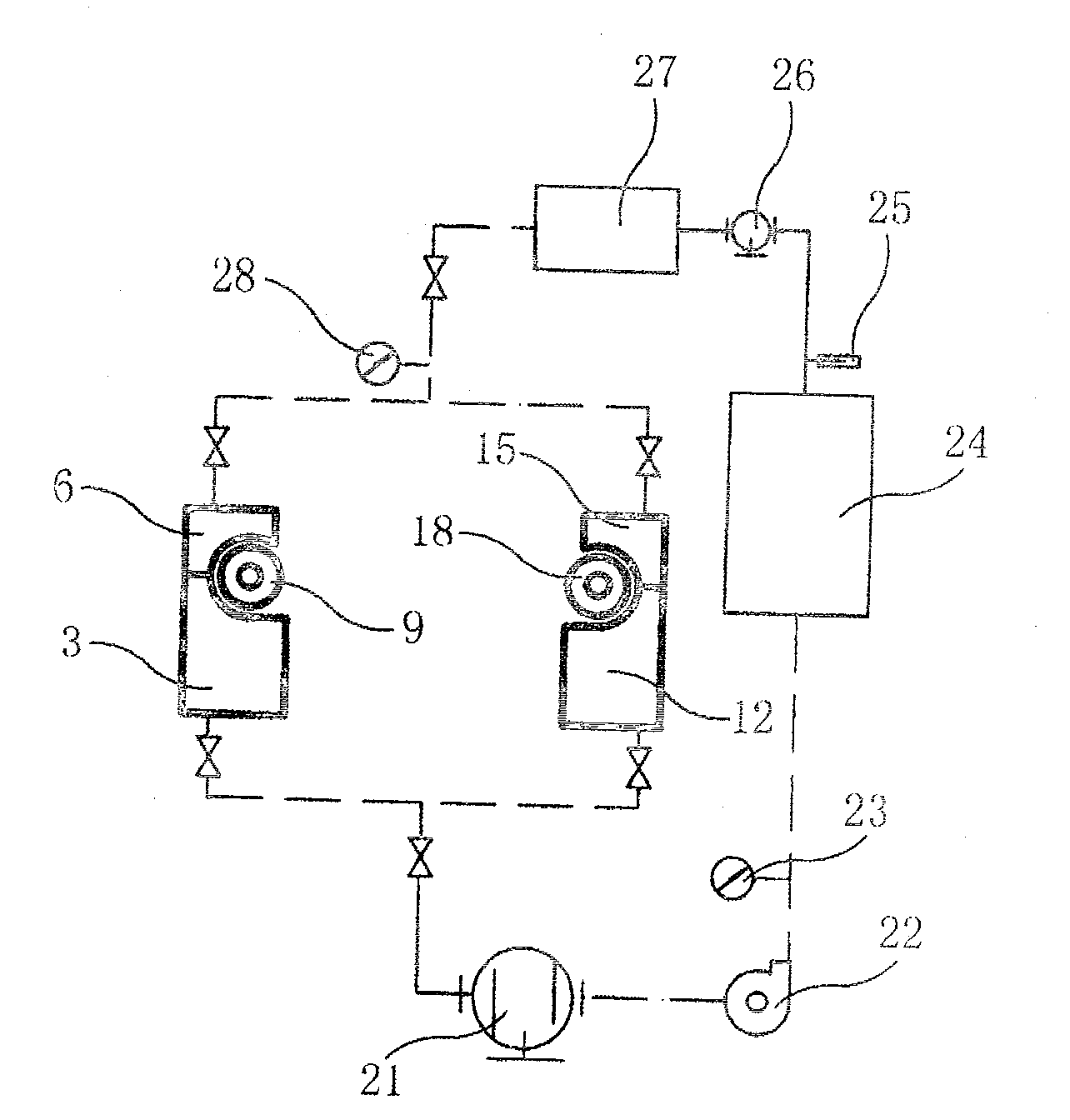

[0030] The wind pressure P of the high-pressure strong wind is 6000Pa, the air volume H is 5000m / h, the wind temperature is about 24°C, the rheumatism is 60%, and the air cleanliness is 5000 grades.

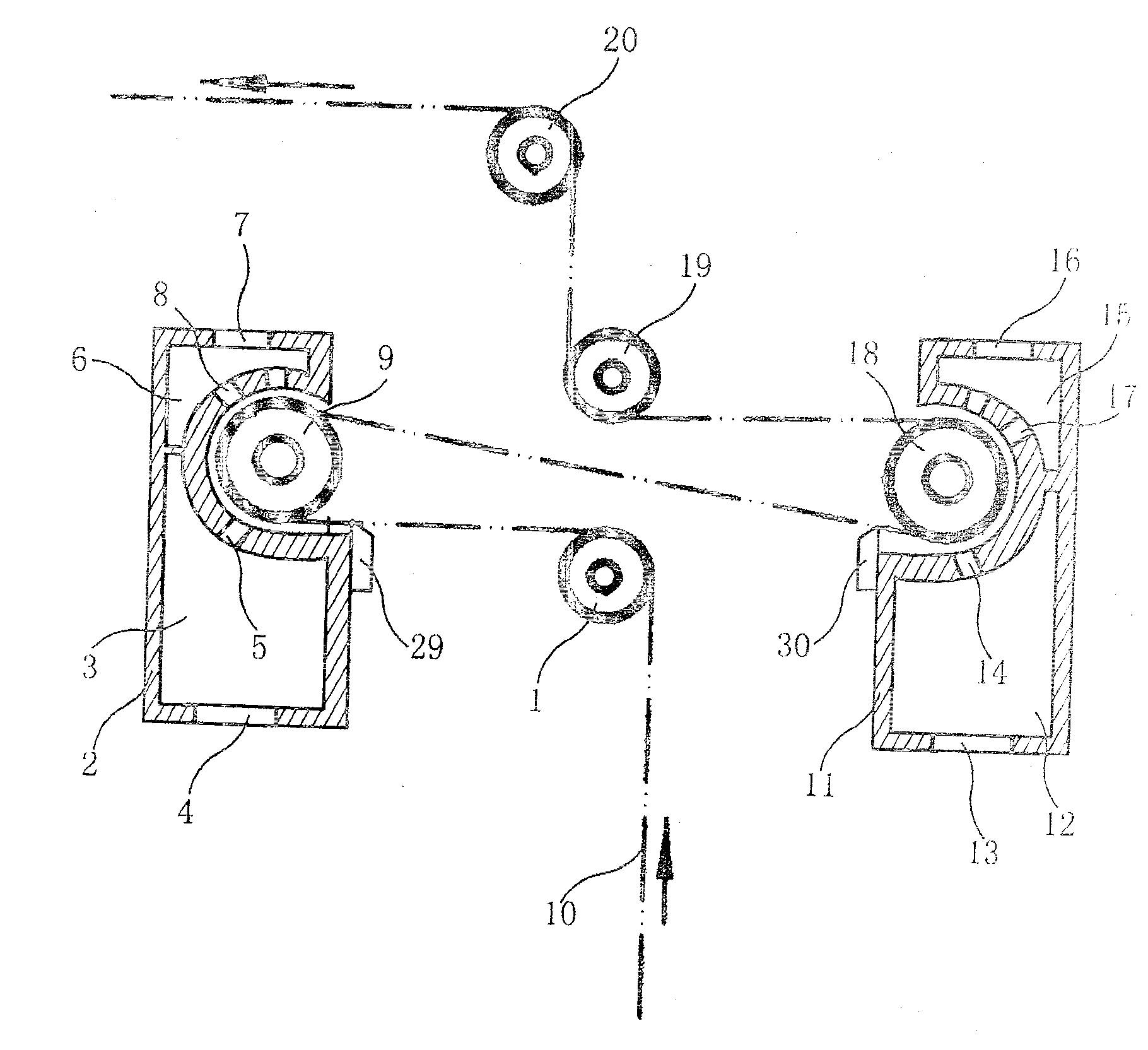

[0031] Such as figure 2 , 3 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com