Experienced driving method for plasma display screen

A plasma and driving method technology, applied in static indicators, cold cathode tubes, instruments, etc., can solve the problems of ignition and low screen forming rate, and achieve the effects of reducing ignition voltage, reducing production costs, and stabilizing working characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] Such as Figure 1-7 shown.

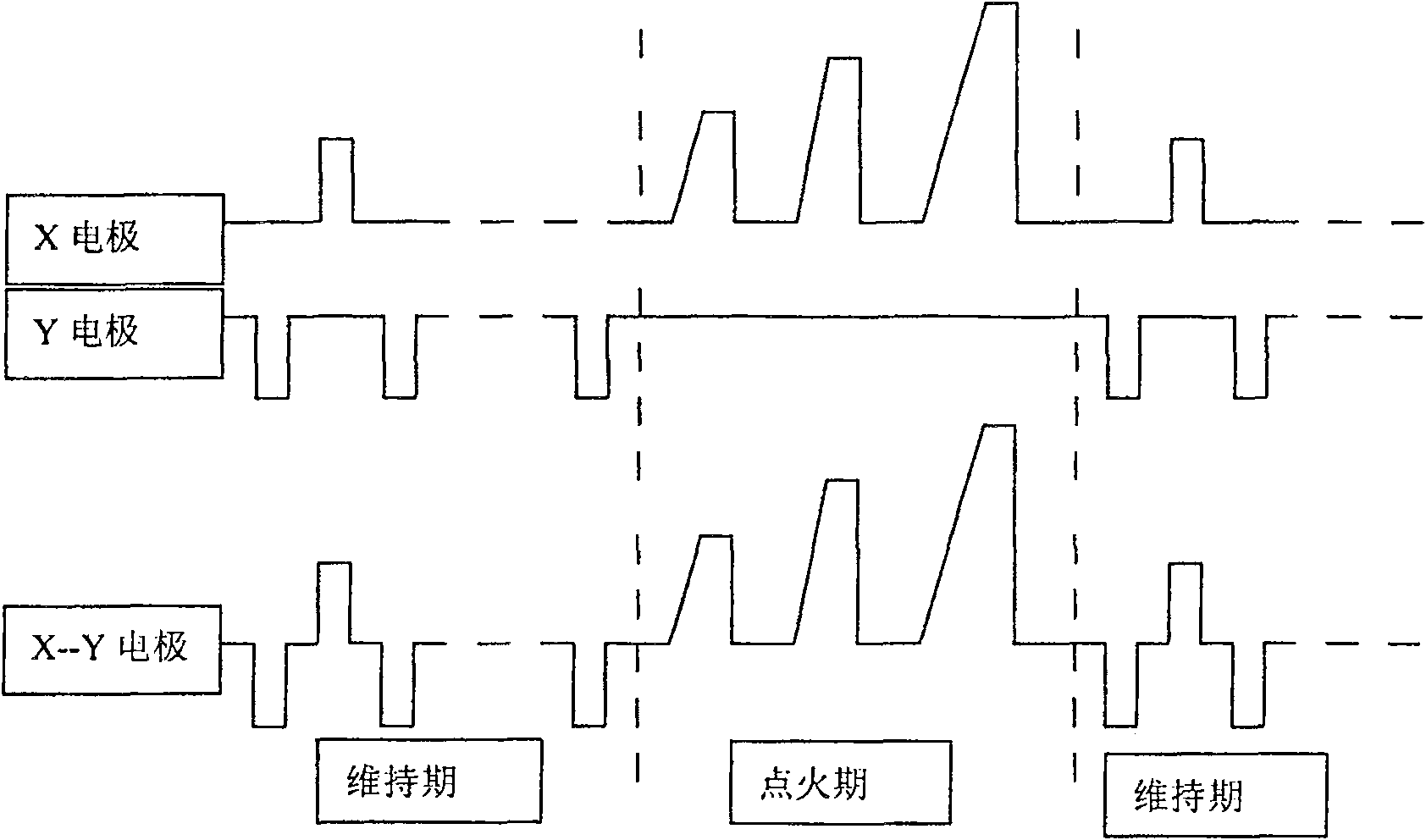

[0027] A burn-in drive method for a plasma display panel, which is different from the existing burn-in method in that when the plasma display screen is burnt-in, at least three connections with different amplitudes and different widths are applied during the ignition period. Pulse voltage, so that the pulse voltage applied to the display screen for the first time gradually increases to reduce the high-voltage impact on the display screen.

[0028] The waveform of the specific applied voltage can be adopted Figure 1 to Figure 7 The waveform shown, where:

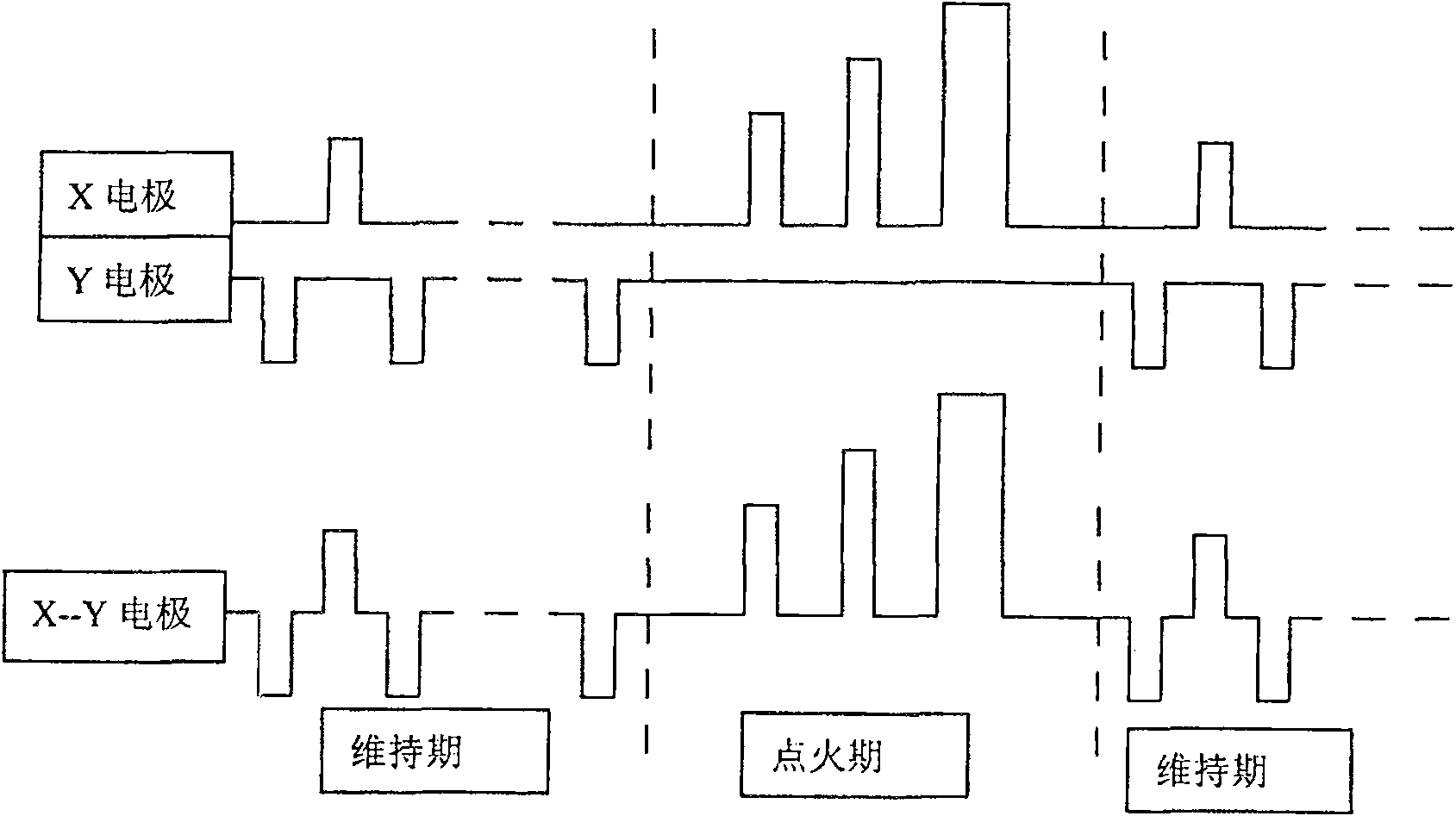

[0029] figure 1 It is one of the new aging driving waveforms of the plasma display screen. During the ignition period, there are three ignition pulse rectangular wave signals with different amplitudes and different widths.

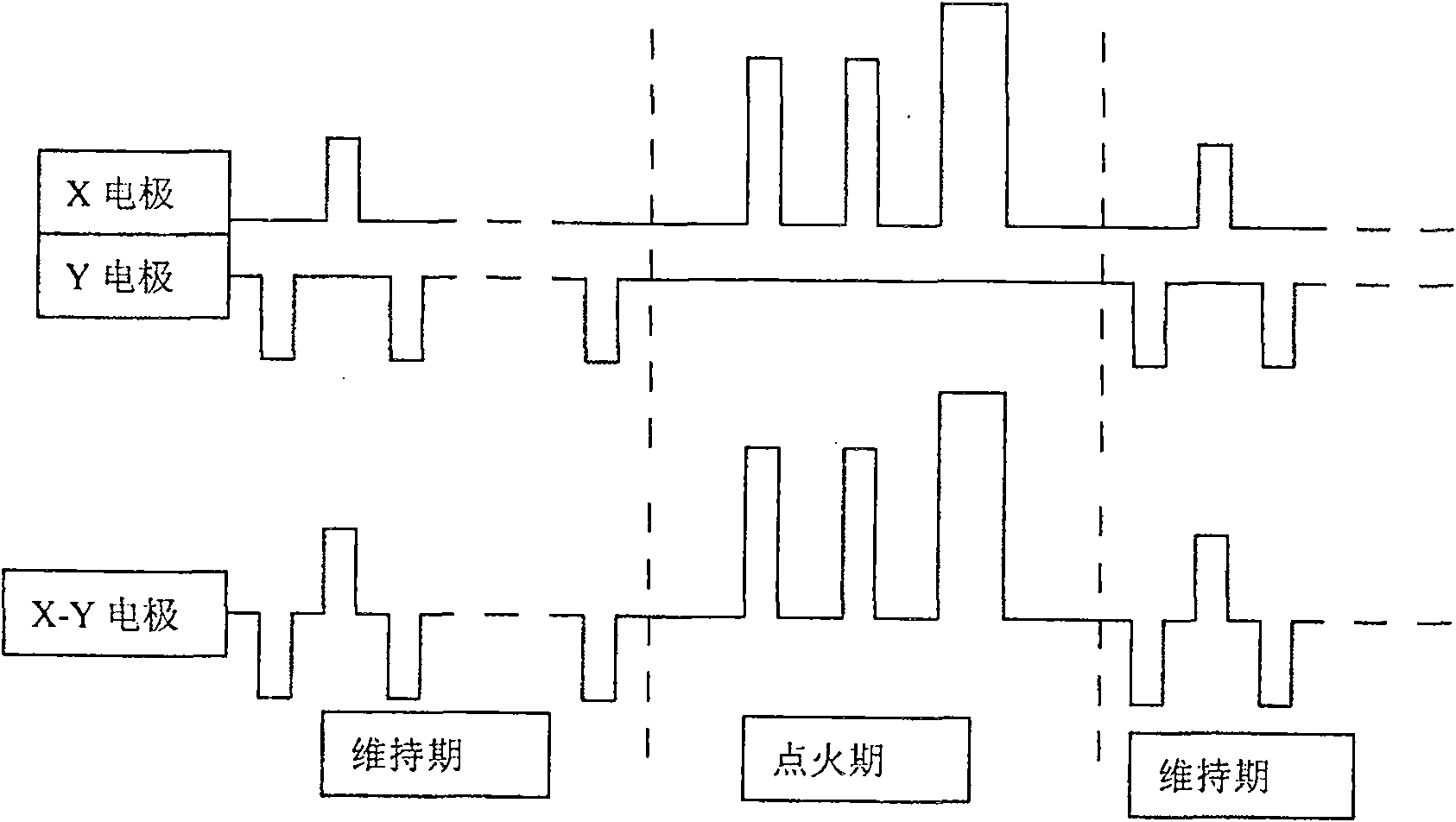

[0030] figure 2 It is the second a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com