Composite cathode high-power plasma generator and arc striking method

A composite cathode and plasma technology, applied in the field of plasma, can solve the problems that restrict the industrial application of high-power plasma generators, affect the discharge stability of plasma heating efficiency, and the gas flow cannot be increased indefinitely, so as to reduce the number of external water circuits. It has the effect of connecting with the gas path, reducing the pipeline arrangement, and having good discharge stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

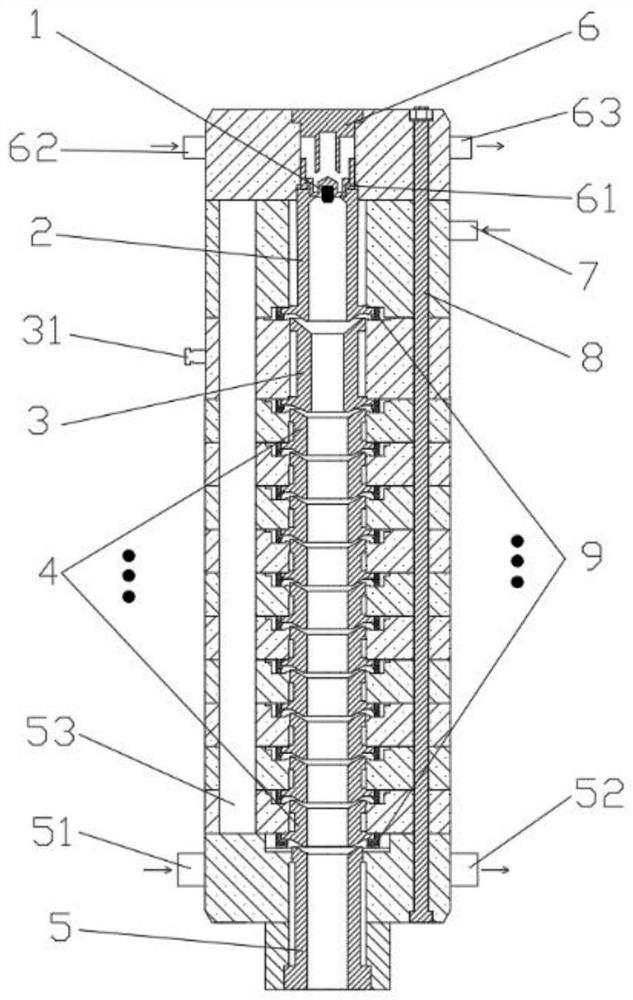

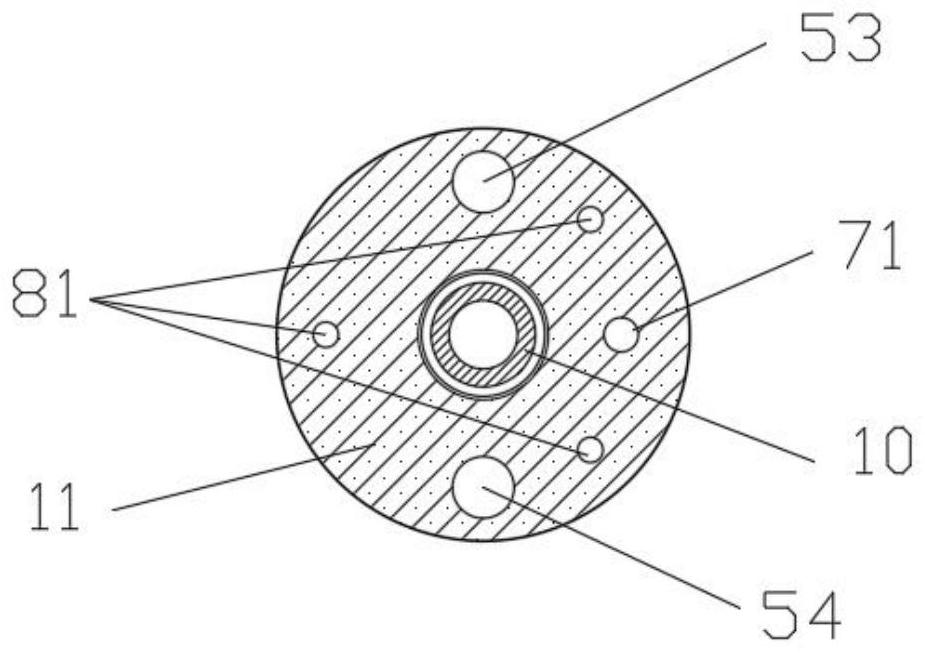

[0038] like figure 1As shown in the figure, a composite cathode high-power plasma generator of the present invention includes a composite cathode, an arc-striking electrode 3, an inter-electrode insert 4, and an anode 5. The composite cathode is composed of an end-face cathode 1 and a ring target cathode. The target cathode is composed of the cathode ring 2 and the internal target working medium. The end-face cathode 1 is located at the uppermost end, and is fixed by the cathode support cooling unit 6. The arc-striking electrode 3 is connected to the cathode ring 2, and then connected to the bottom one by one. The inter-electrode inserts 4 are finally connected to the anode 5. The end-face cathode 1, the cathode ring 2, the arc-striking electrode 3, the inter-electrode insert 4, and the outer ring of the anode 5 are all fixed by an independent insulating ring 11, forming a modular structure. The circumferentially distributed pressing rods 8 are coaxially tightly insulated and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com