Phase control annular ultrasound focusing method

A technology of ultrasonic focusing and phase control, which is applied in the direction of fluid using vibration, etc., which can solve the problems of poor focusing effect of ultrasonic energy, damage to non-working areas, and waste of sound energy in non-working areas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

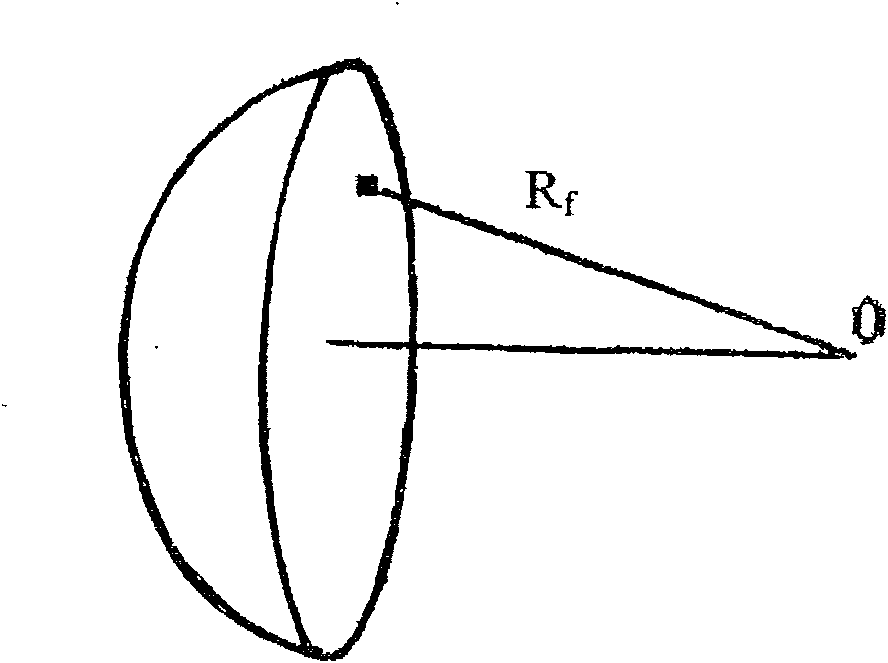

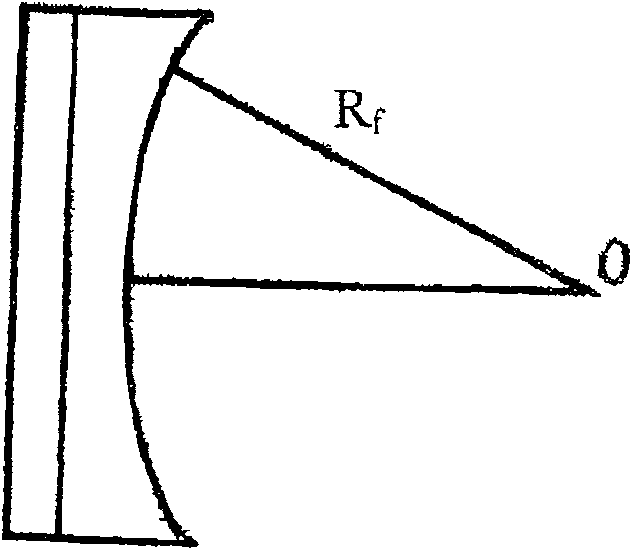

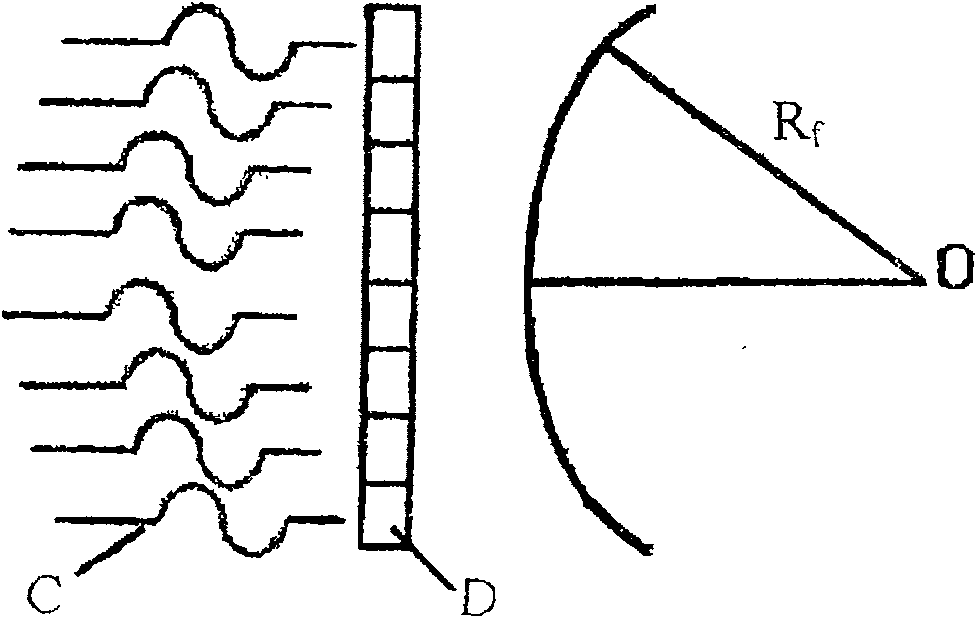

[0045] In order to further illustrate the content, technical characteristics and effects of the present invention, the following examples are given and described below in conjunction with the accompanying drawings: as Figure 11 The phase control annular ultrasonic focusing method of the present invention shown includes the following stages

[0046] S1: The stage of determining the position and size of the target according to the measurement; S2: Setting the ring position R according to the distance from the edge of the target to the ultrasonic transducer array h stage; S3: Determine the actual focus position (working position) R according to the size of the work target and the planned work position f And by the formula (3) namely R f =R h +2d+6.0(mm) is the stage of calculating the ring diameter d; S4: the stage of precisely adjusting and controlling the working position; S5: according to the formula (1), (2) that is

[0047] t 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com