Substrate recognition method and element mounting system

A technology of installation system and identification method, which is applied in the direction of electrical components, electrical components, etc., can solve problems such as hindering installation processing, shortening production rhythm, and increasing the processing burden of installation machines, so as to achieve the effect of smooth production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described below with reference to the drawings.

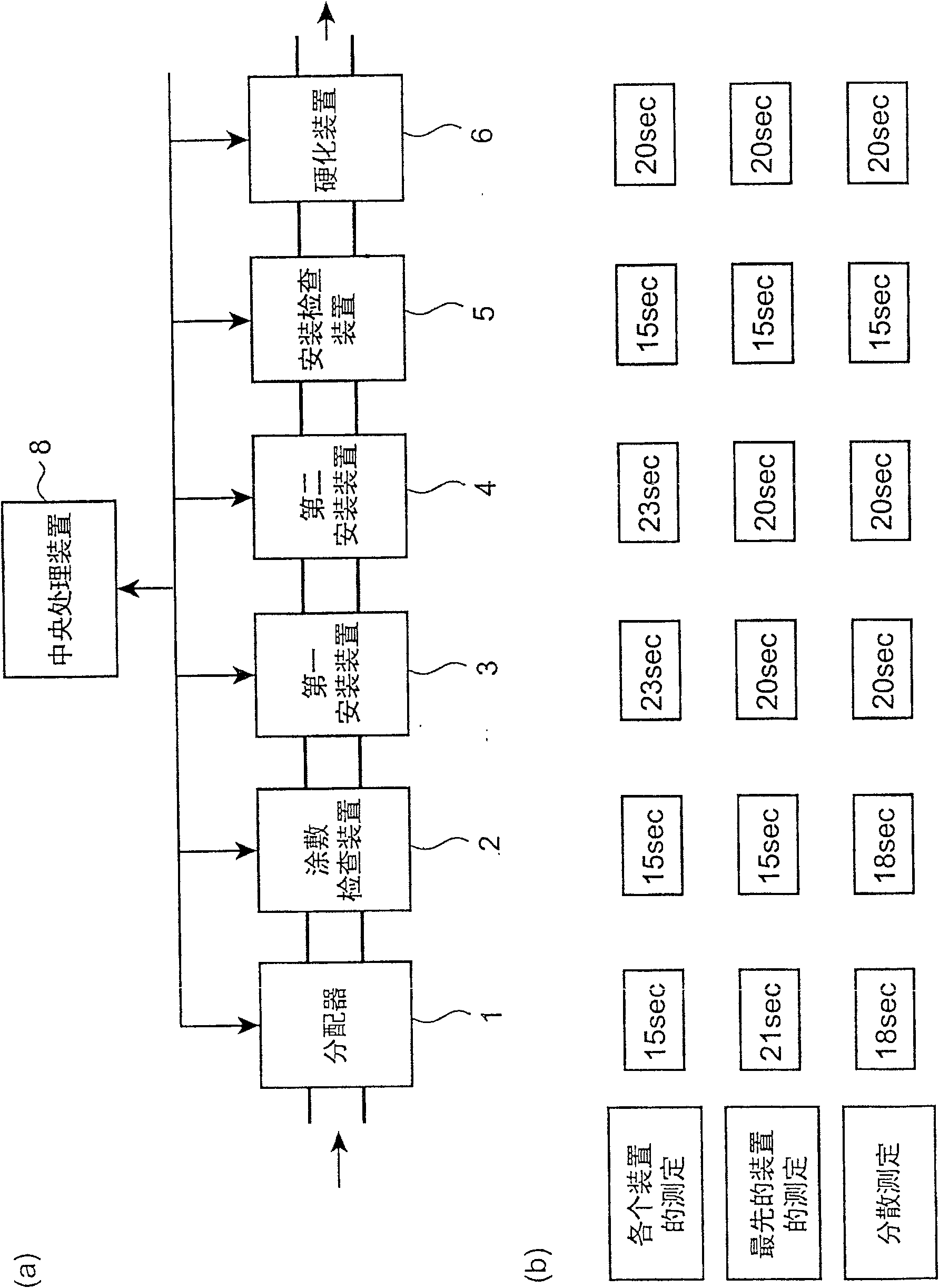

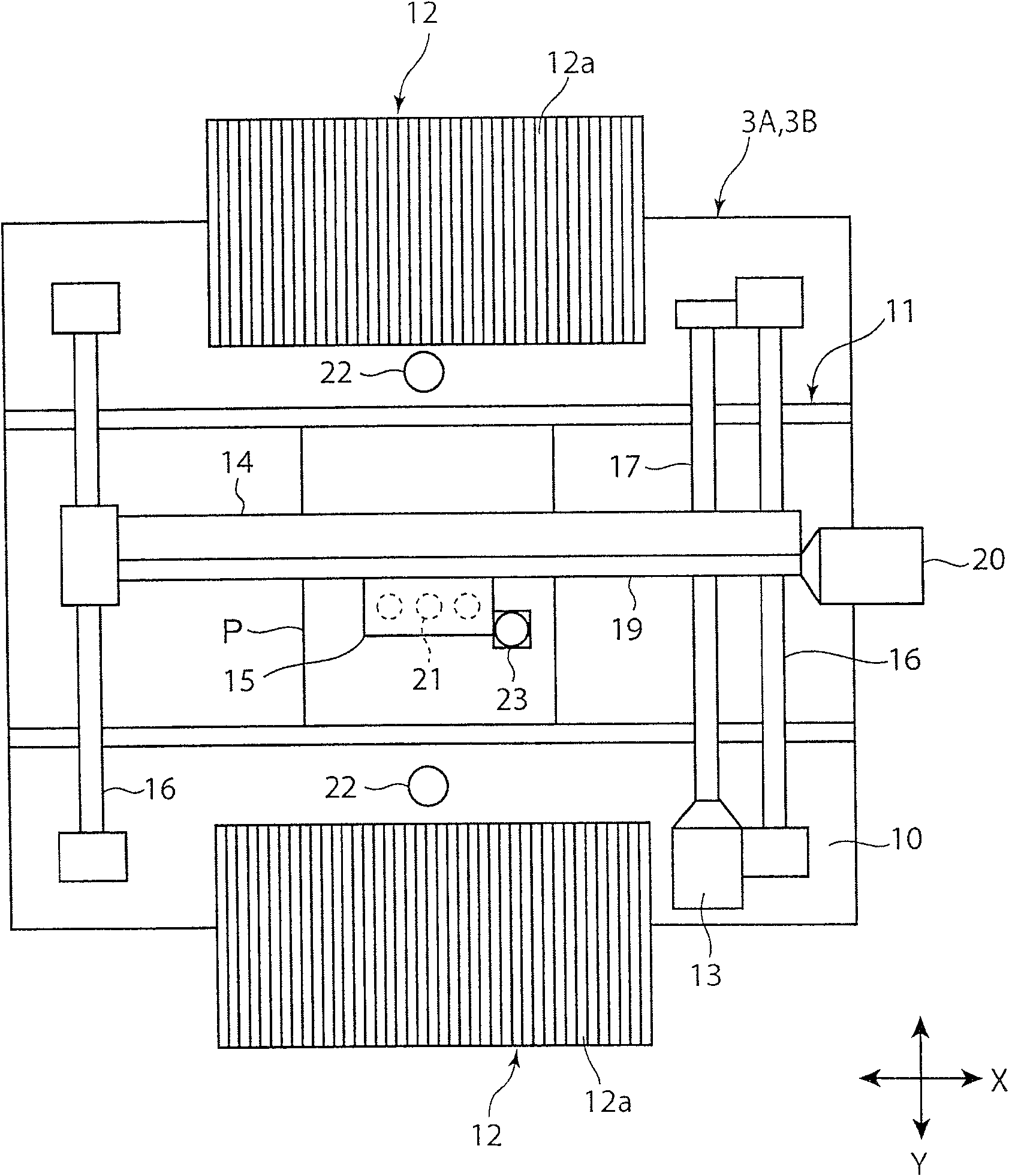

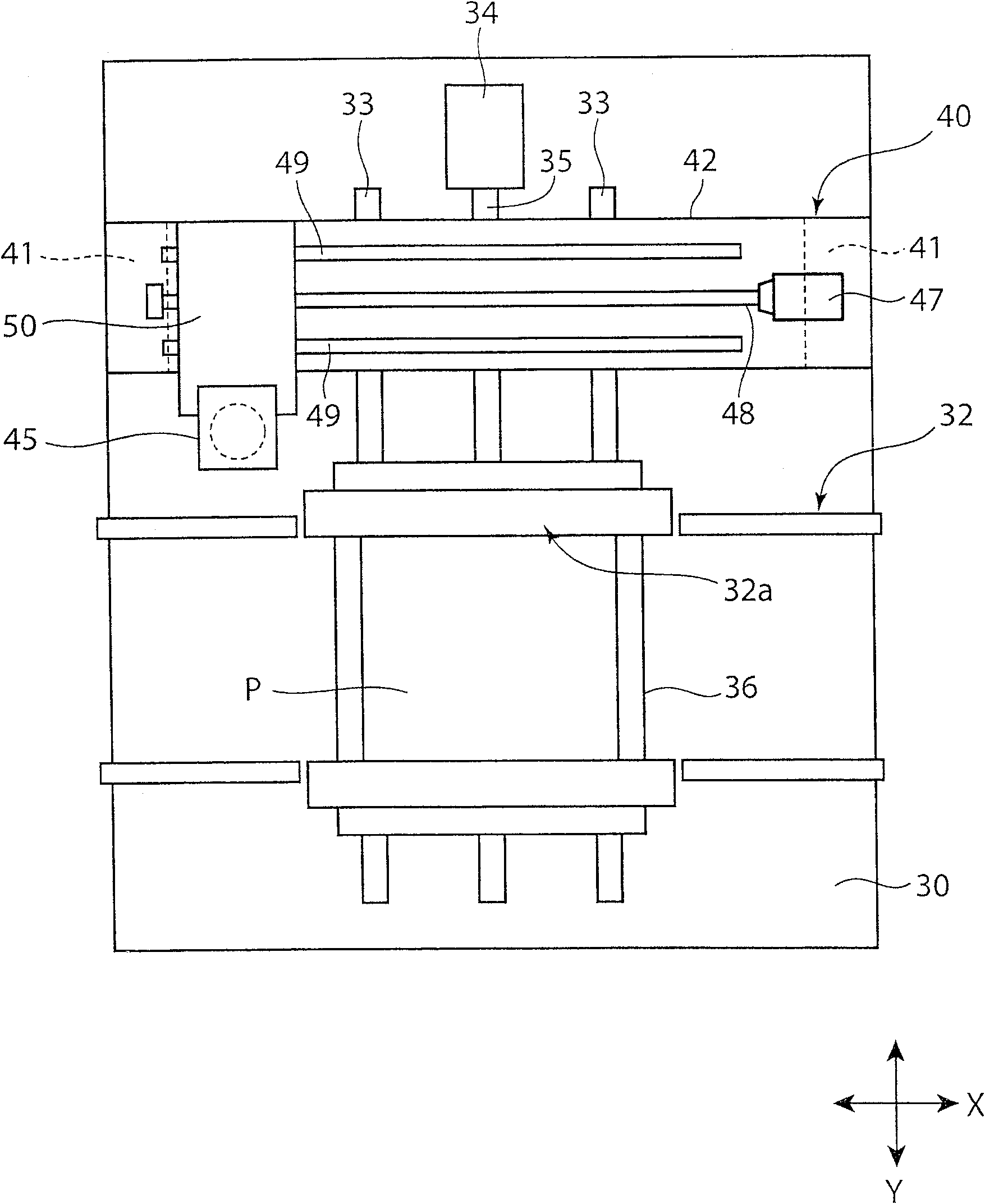

[0027] figure 1 (a) schematically shows a component mounting line related to the component mounting system of the present invention (a component mounting system for substrate identification according to the present invention). In this production line, a dispenser 1, a coating inspection device 2, a first mounting device 3, and a second mounting device 4 are arranged in series between a loader and an unloader (both are not shown in the figure). , Install inspection device 5 and hardening device 6 and constitute. Furthermore, its structure is as follows: While conveying a circuit board (hereinafter simply referred to as a substrate), it sequentially applies solder paste, performs various processes such as component mounting and solder paste hardening, and at the same time inspects the solder paste application process by the application inspection device 2. substrate, and use t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com