Process for making beer malt

A malt and beer technology, applied in the field of malt preparation, can solve the problems of high cost and large water and electricity consumption, and achieve the effects of cost reduction, water and electricity consumption reduction, and increased selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a malting process for high-end beer malt, comprising the following steps:

[0028] Barley immersion: use the Canadian barley Metcalfe variety with a single batch feeding capacity of 265 tons, water at a rate of 500 tons / hour for 0.6h, and then use three times of wet soaking and three dry soaking alternately, and three times of wet soaking adopt continuous overflow (overflow rate of 100 tons / hour), the time is 6h, 3h, 2h in sequence; the air inlet temperature is 15°C during dry leaching, and the exhaust air temperature is 18°C; the time for three times of dry immersion is 7h, 3h, 2h in turn. The water temperature during the soaking process is 15°C; the outcropping rate of wheat grains after soaking is 97%; the soaking degree of wheat grains is 40.5%. The power consumption of the malt soaking step is 1575 degrees, and the power consumption per ton of malt is 7.5 degrees.

[0029] Germination: germinate the above-mentioned soaked wheat grains unde...

Embodiment 2

[0034] The present embodiment provides a kind of malting process of beer malt, comprising the following steps:

[0035] Barley immersion: using a single batch of 265 tons of Canadian barley Metcalfe, watering at a rate of 300 tons per hour for 0.6h, and then using three times of wet soaking and three dry soaking alternately, and three times of wet soaking using continuous overflow (overflow rate of 50 tons / hour), the time is 4h, 1h, 1h in sequence; the air inlet temperature is 21°C during dry immersion, and the exhaust air temperature is 23°C; the time for three times of dry immersion is 5h, 2h, 1h in turn. The water temperature during the soaking process is 18°C; the outcropping rate of wheat grains after soaking is 97%; the soaking degree of wheat grains is 40.5%. The power consumption of the soaking step is 777 tons, and the power consumption is 3.7 degrees.

[0036] Germination: germinate the wheat grains after soaking the above-mentioned wheat under the conditions that...

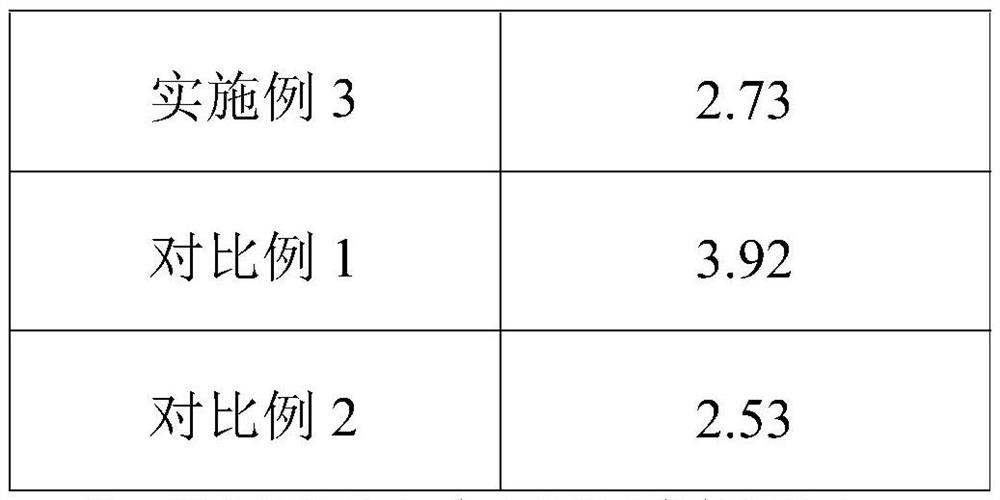

Embodiment 3

[0041] The present embodiment provides a kind of malting process of beer malt, comprising the following steps:

[0042] Barley immersion: Use Canadian barley Metcalfe variety with a single batch feeding capacity of 265 tons and water at a rate of 400 tons / hour for 0.6h, and then use three wet soaks and three dry soaks alternately, and three wet soaks use continuous overflow (overflow rate is 80 tons / hour), the time is 5h, 2.5h, 1h in sequence; the air inlet temperature is 18°C during dry immersion, and the exhaust air temperature is 21°C; the time for three times of dry immersion is 6h, 2.5h, 1.5h in turn. The water temperature during the soaking process is 16°C; the outcropping rate of wheat grains after soaking is 97%; the soaking degree of wheat grains is 40%. The electricity consumption of the malt soaking step is 1260 degrees, and the electricity consumption per ton of malt is 6.0 degrees.

[0043] Germination: germinate the above-mentioned soaked wheat grains under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com