Container transportation method and system for container production line

A container and production line technology, applied in the direction of transportation and packaging, conveyor control devices, conveyor objects, etc., can solve the problems of high temperature in the drying room, health hazards of workers, waste of labor, etc., to achieve stable transportation and improve the working environment of workers , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

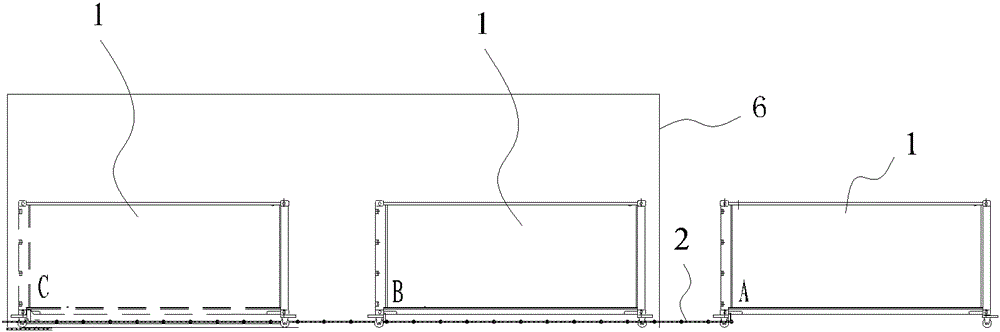

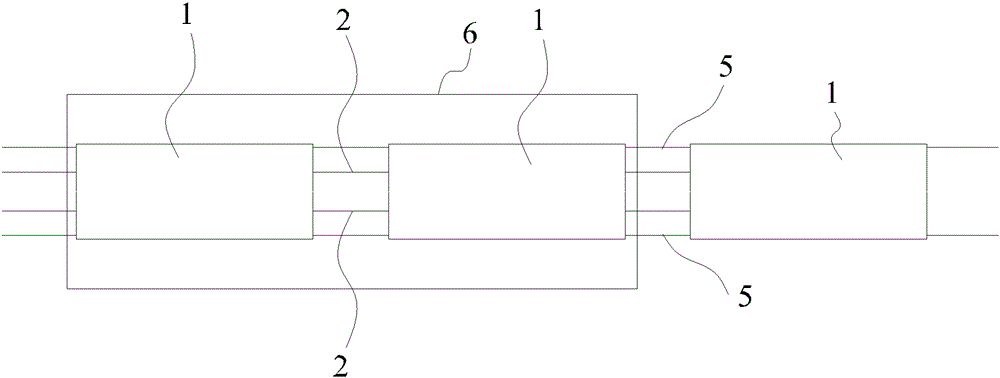

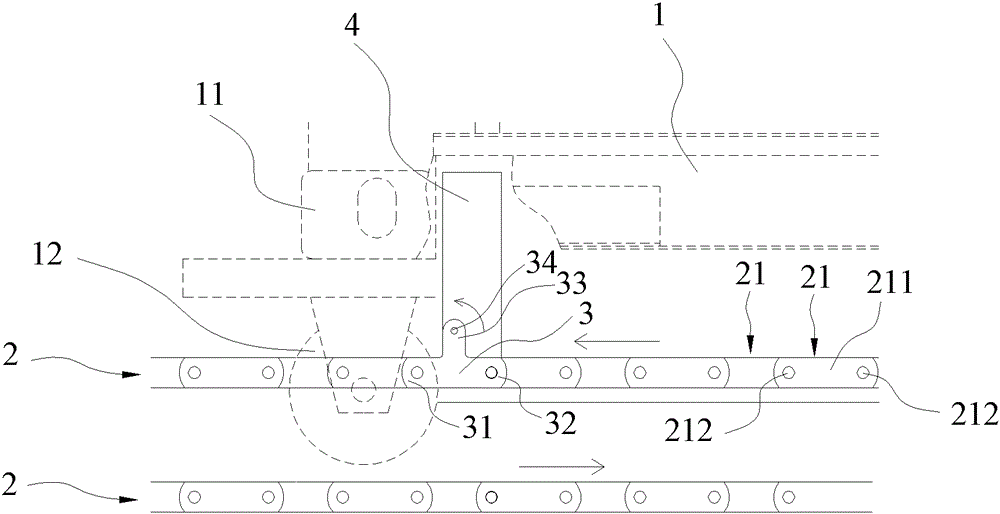

[0018] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0019] The container transportation method of the container production line of the present invention includes the following steps.

[0020] Step 1: Set two container transport tracks, and set at least one conveyor belt between the two transport tracks, and set a plurality of push blocks protruding upward from the conveyor belt at intervals on each conveyor belt.

[0021] Step 2: Install rollers on the bottom of the container to be transported, make the rollers of the container on the track, and make the push block on the conveyor belt extend into the bottom of the container.

[0022] Step 3: Control the conveyor belt to run or stop according to the set production beat, so that the push blocks on the conveyor belt also push the container to move or stop along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com