Multi-breed multi-order high-speed sorting table system and sorting method thereof

A sorting table and multi-variety technology, applied in the direction of sorting, conveyor control devices, conveyor objects, etc., can solve the problems of not being able to adapt to the automatic conveyor system or automatic storage system, high labor intensity, low degree of automation, etc., to achieve Strong applicability and integrability, low training and labor costs, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

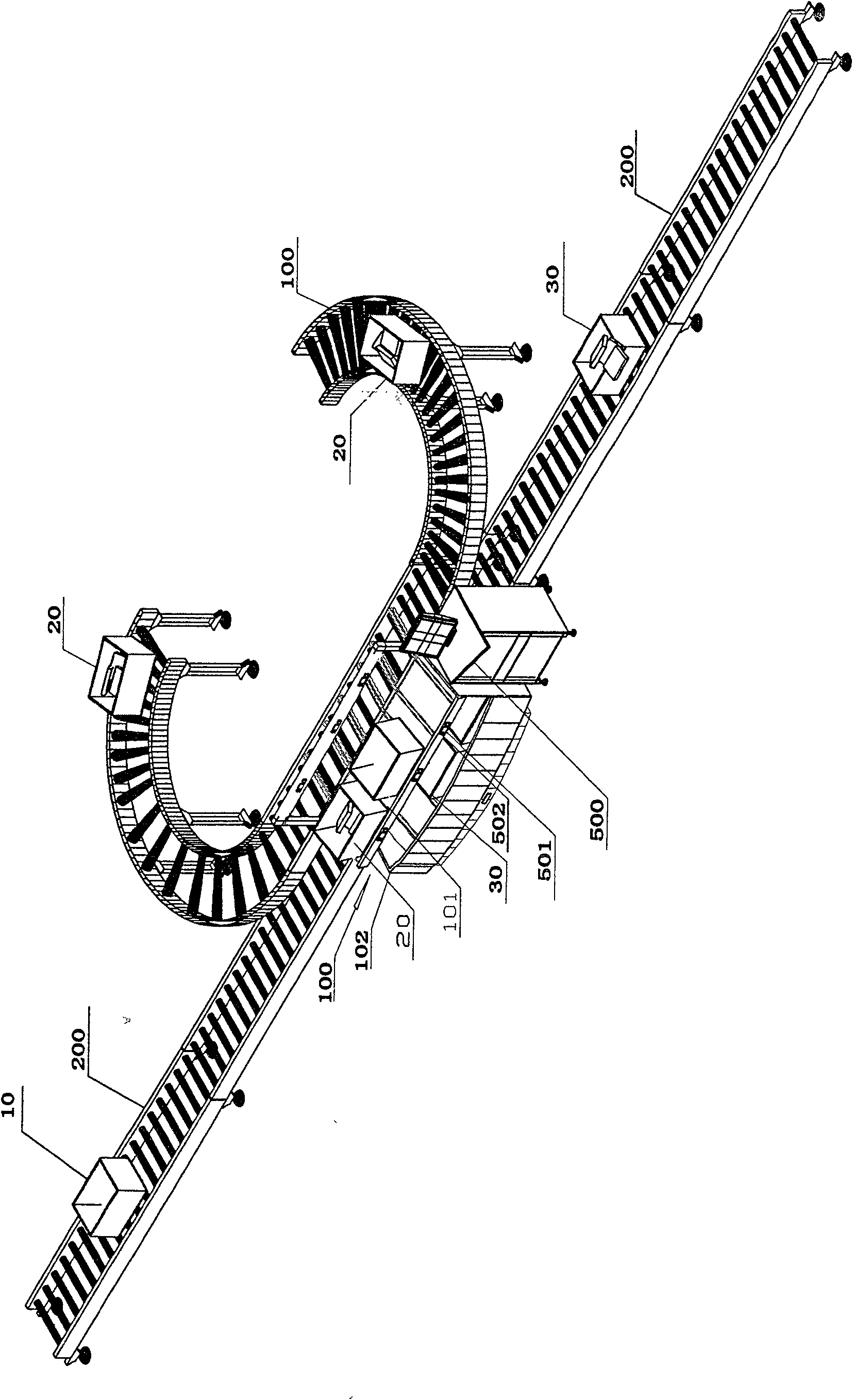

[0037] What present embodiment provides is the sorting platform system that only contains one sorting platform 100, can be provided with a plurality of sorting platforms for very large-scale sorting platform system, figure 2 Shown is a picker system comprising two picker beds 100 .

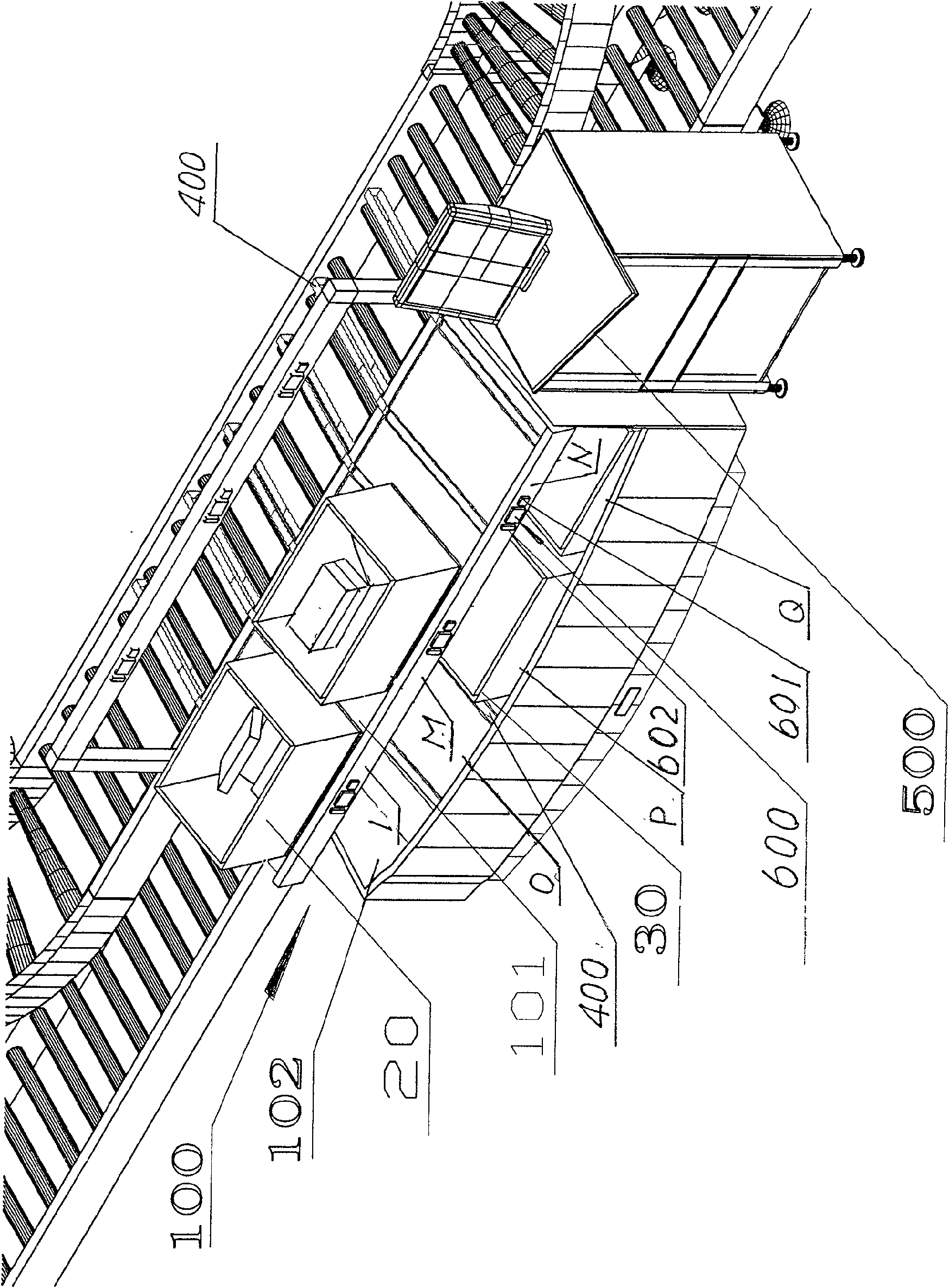

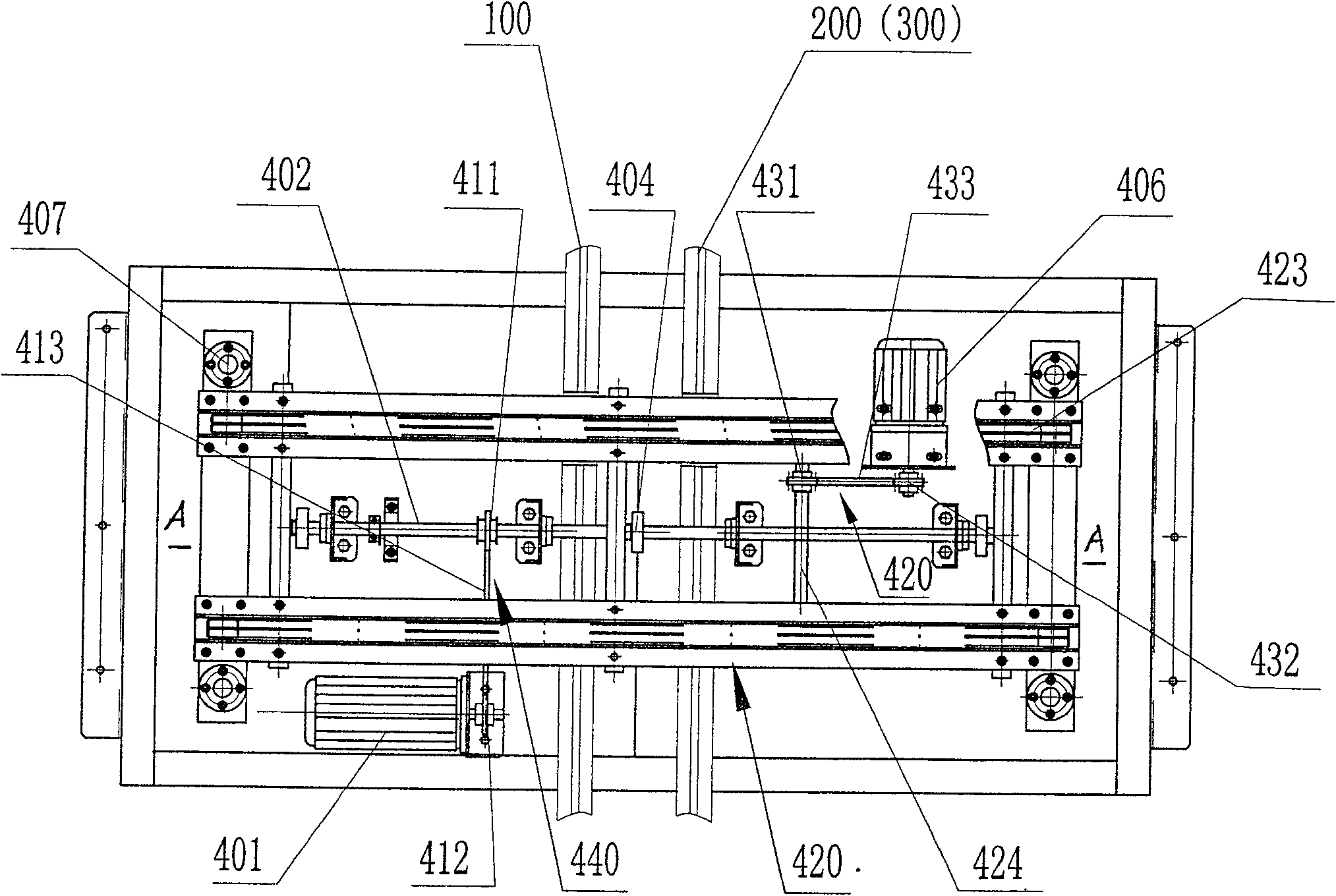

[0038] control figure 1 , On one side of the sorting table 100, there are upper and lower two-layer roller conveying lines, the upper conveying line 200 is circular and used for supply, and the lower conveying line 300 is linear and used for shipment. The picking table 100 is provided with upper and lower two-layer workbenches, and the upper workbench is provided with a supply buffer area 200 with three parallel boxes for temporarily storing the supply boxes 20 of the picked goods, corresponding to each An electronic display label 600 that is provided with an indicator light 602, a confirmation key 601 and a display screen is installed at the position of the box position. Similarly, the lower w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com