Jet-attract form gasoline cutting torch

A jet-suction, gasoline technology, applied in the direction of gas fuel burner, combustion method, combustion type, etc., can solve the poor coordination of design parts and internal parts, without considering the principle of cutting torch atomization, and not really exerting the ejection suction and other issues, to achieve the effect of easy assembly and maintenance, avoiding inconvenient assembly and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

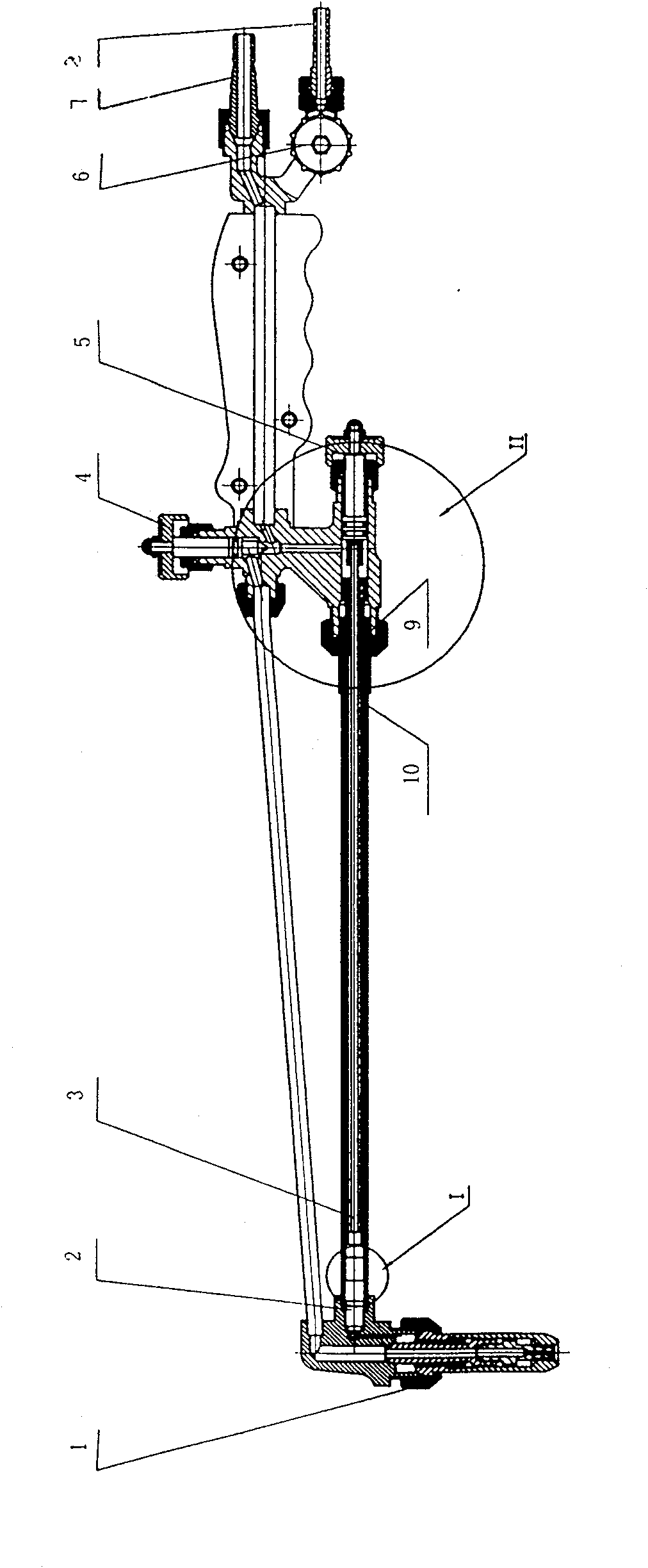

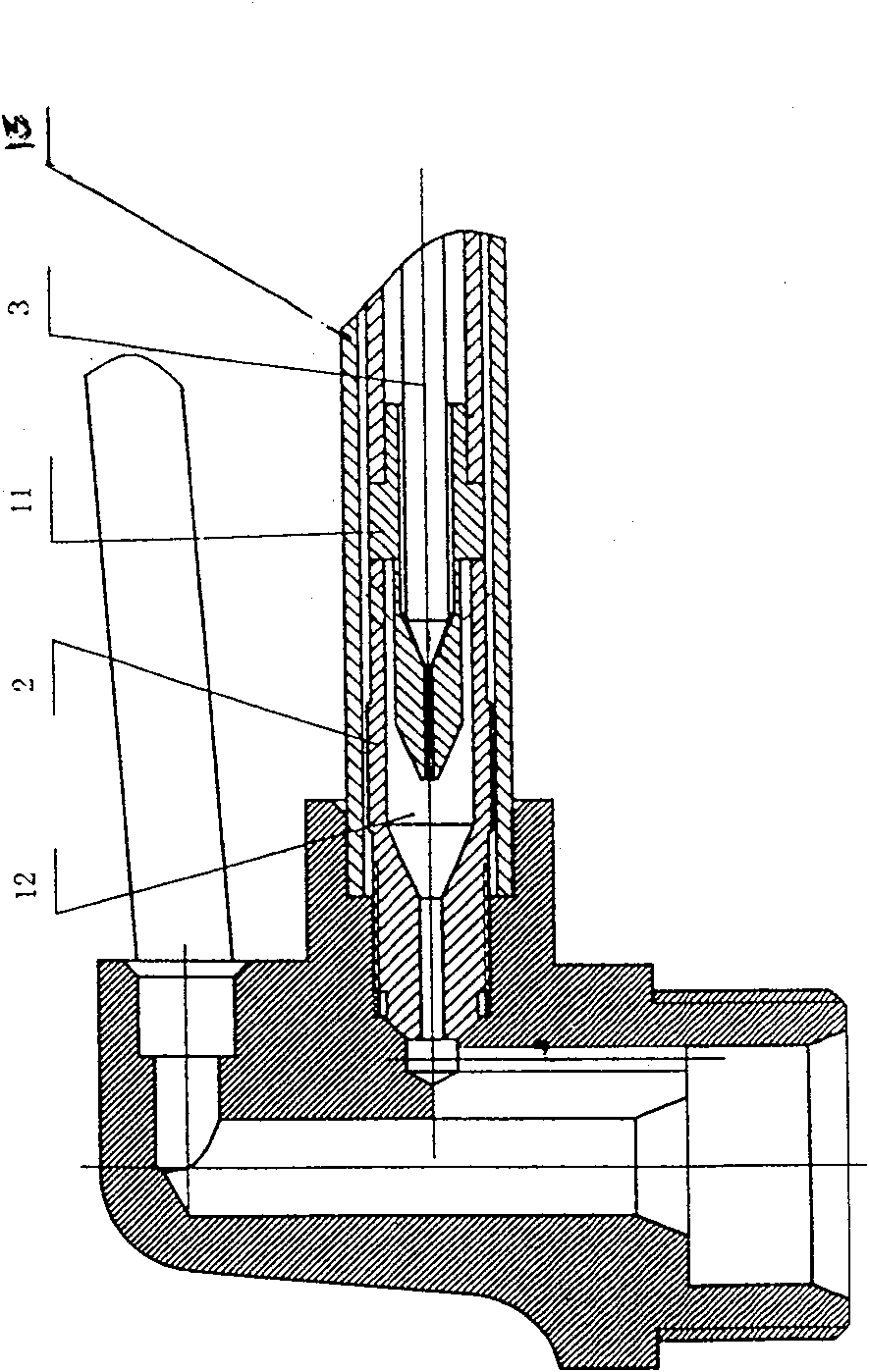

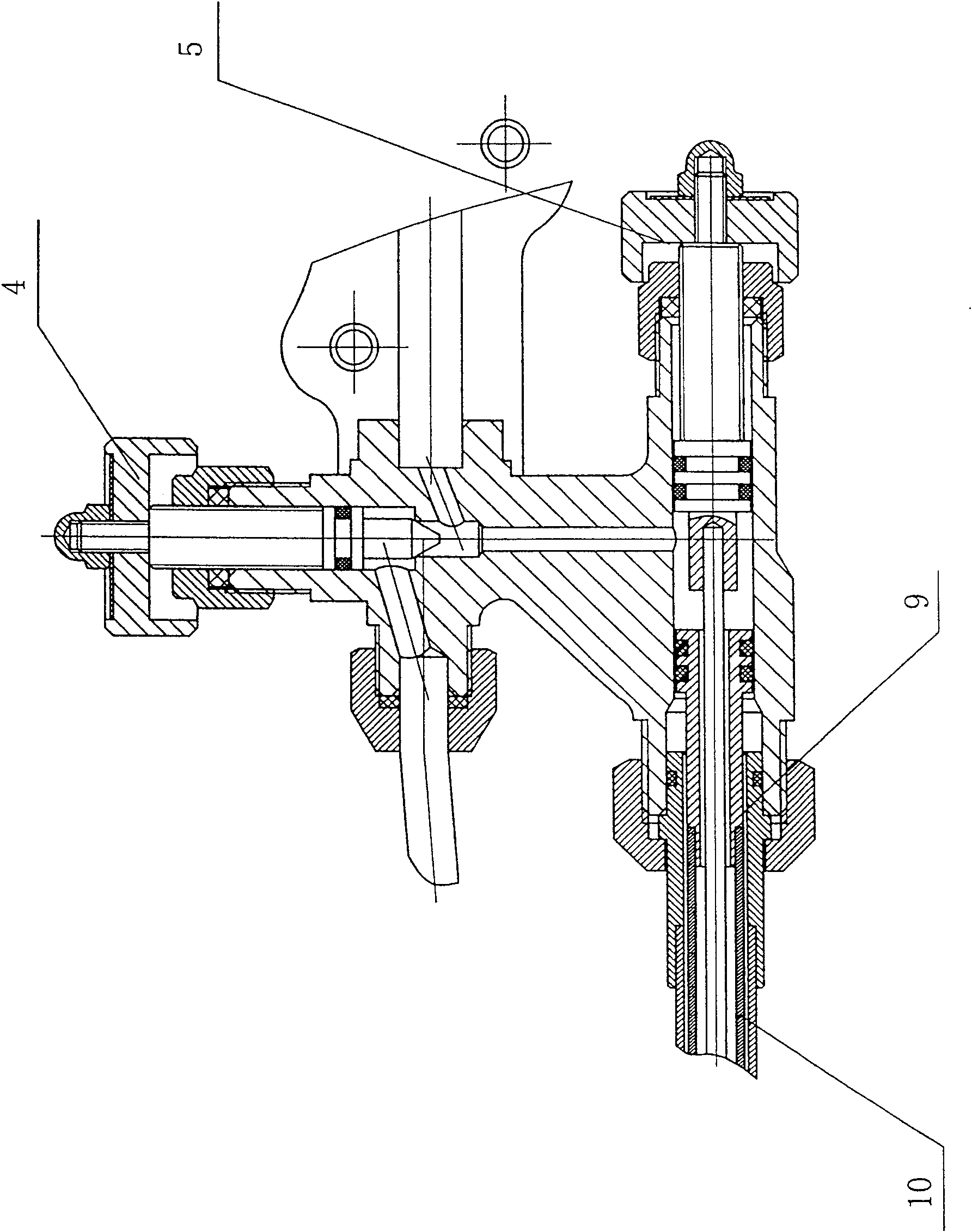

[0027] Below, please refer to figure 1 Schematic diagram of the jet-suction gasoline cutting torch and figure 2 It is an enlarged cross-sectional view of the vacuum injection chamber of part I of the injection-suction gasoline cutting torch, illustrating the structural features of the parts of the injection-suction part;

[0028] One end of the connecting pipe 10 is a small cylindrical surface, the other end is a large cylindrical surface, the large cylindrical end has a groove, and the center is an inner cylindrical surface;

[0029] The shape of the suction pipe 2 is cylindrical, with a middle hole in the middle, an outer cone at the outer circle of one end, an inner cone at the middle hole, and a cylindrical surface at the outer circle of the other end. hole;

[0030] The shape of the nozzle 11 is cylindrical, with a middle hole pipe in the middle, an outer cone surface at the outer circle of one end, an inner cone surface at the middle hole, and a cylindrical surface at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com