Double-core double-seat wash-free stop valve

A shut-off valve and valve core technology, applied in the field of shut-off valves, can solve the problems of short service life, long complete sealing process, high production cost, and achieve the effects of wide medium temperature adaptation range, reduced production cost, and strong erosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In the following, with reference to the drawings and preferred embodiments, the specific implementation, structure, features and functions of the double-core, double-seat non-scouring stop valve proposed by the present invention are described in detail below.

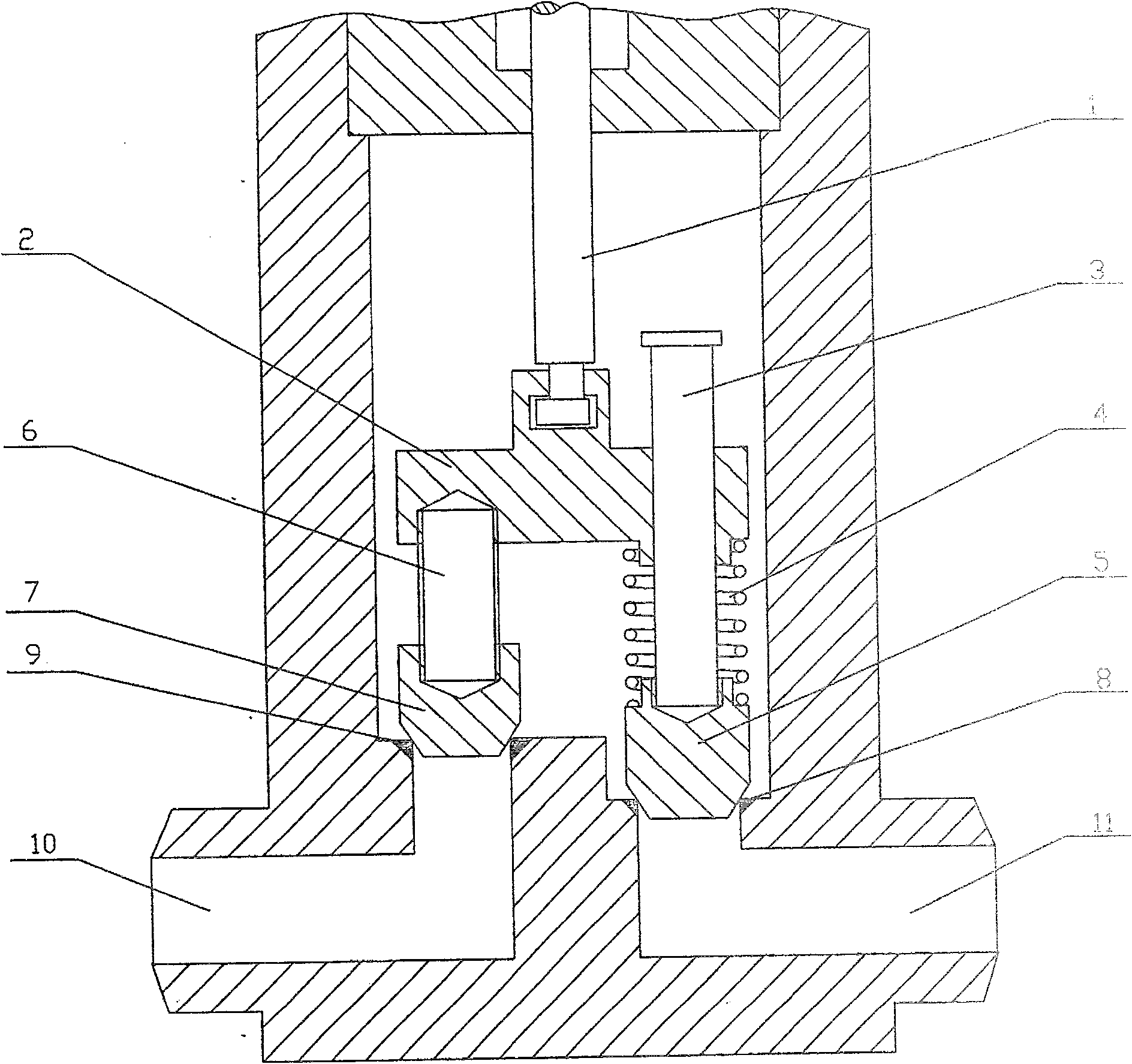

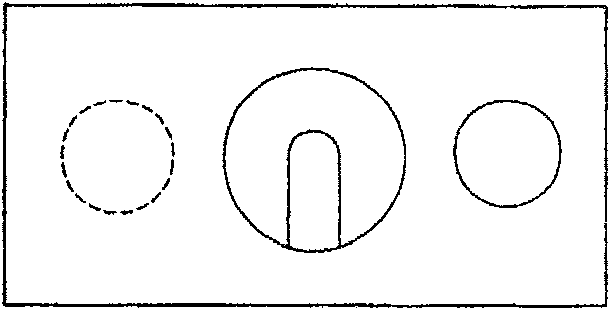

[0018] see Figure 1-2 , double-core double-seat non-scouring globe valve, including a sealing device, a valve body with an inlet flow channel, an outlet flow channel and a valve seat. The structure of the sealing device is that the bottom end of the valve stem A1 is connected to the valve core A2, and the valve stem B3 is in turn Through the round hole in the spool A2, the spring 4 is connected to the spool B5, one end of the valve stem C6 is connected to the spool A2, and the other end is connected to the spool C7; the bottom of the spool B5 and the spool C7 are conical, respectively Valve seat A8 and valve seat B9 match.

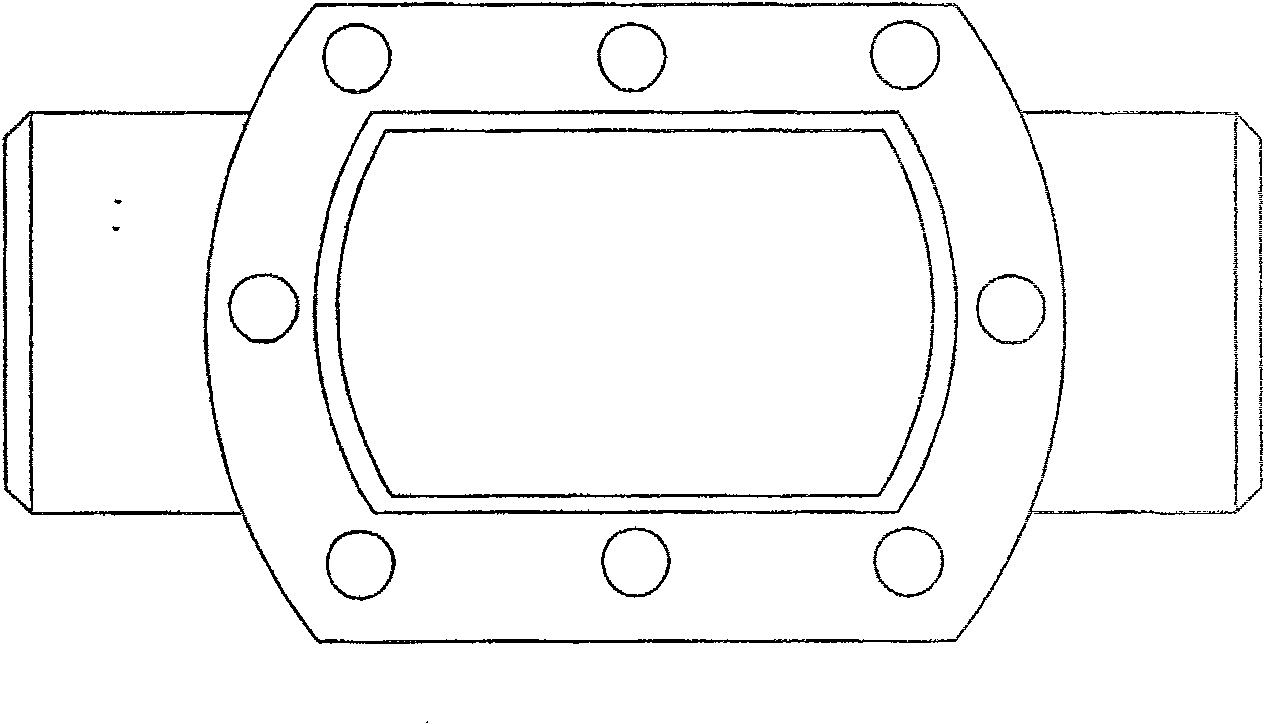

[0019] see image 3 , the shape of the valve body is a flat cylinder surrounded by two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com