Hollow pattern template vertical circulating system for making decorative board and technological method

A pattern template, circulation system technology, applied in the direction of manufacturing tools, supply devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0125] Now a kind of hollow hole pattern template vertical circulation system and process method of the present invention for making decorative plates is specifically described as follows:

[0126] 1) Prepare porcelain raw materials in three colors of dark green, light green and black, and put them into three containers respectively.

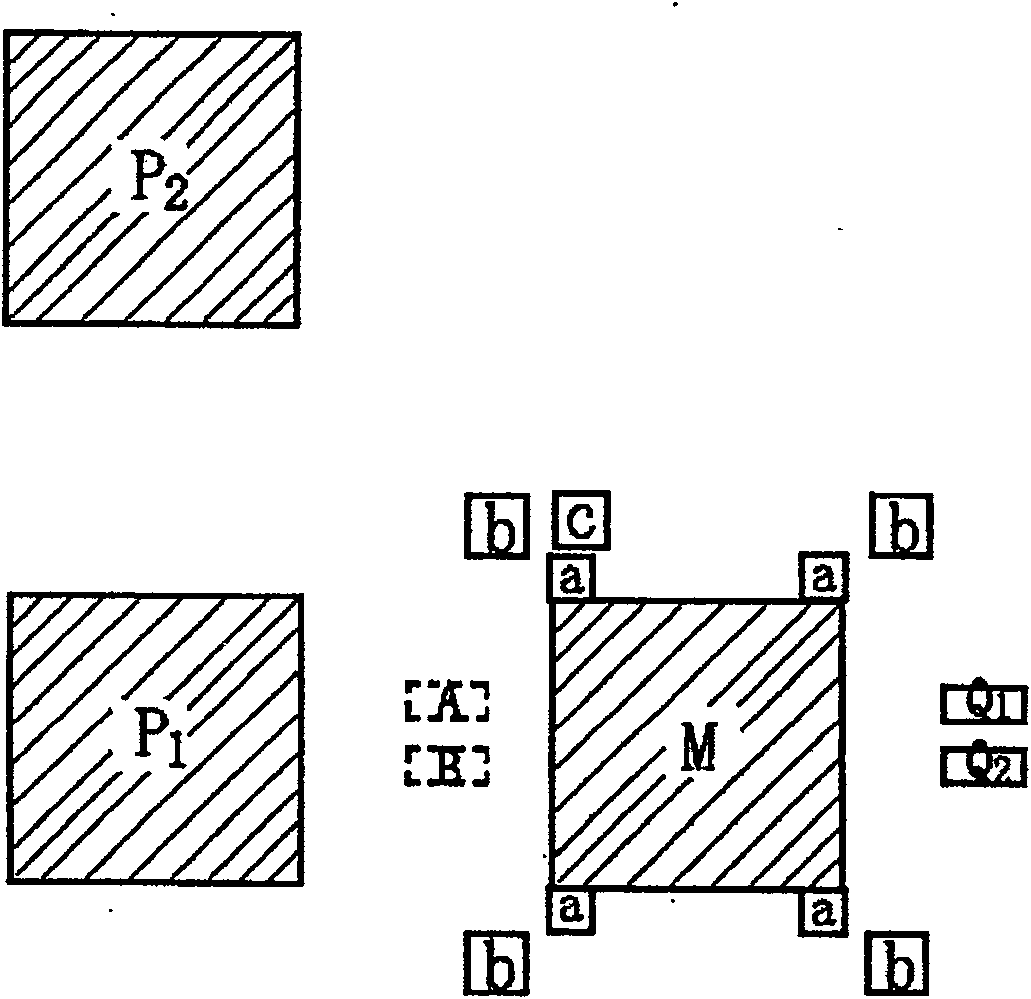

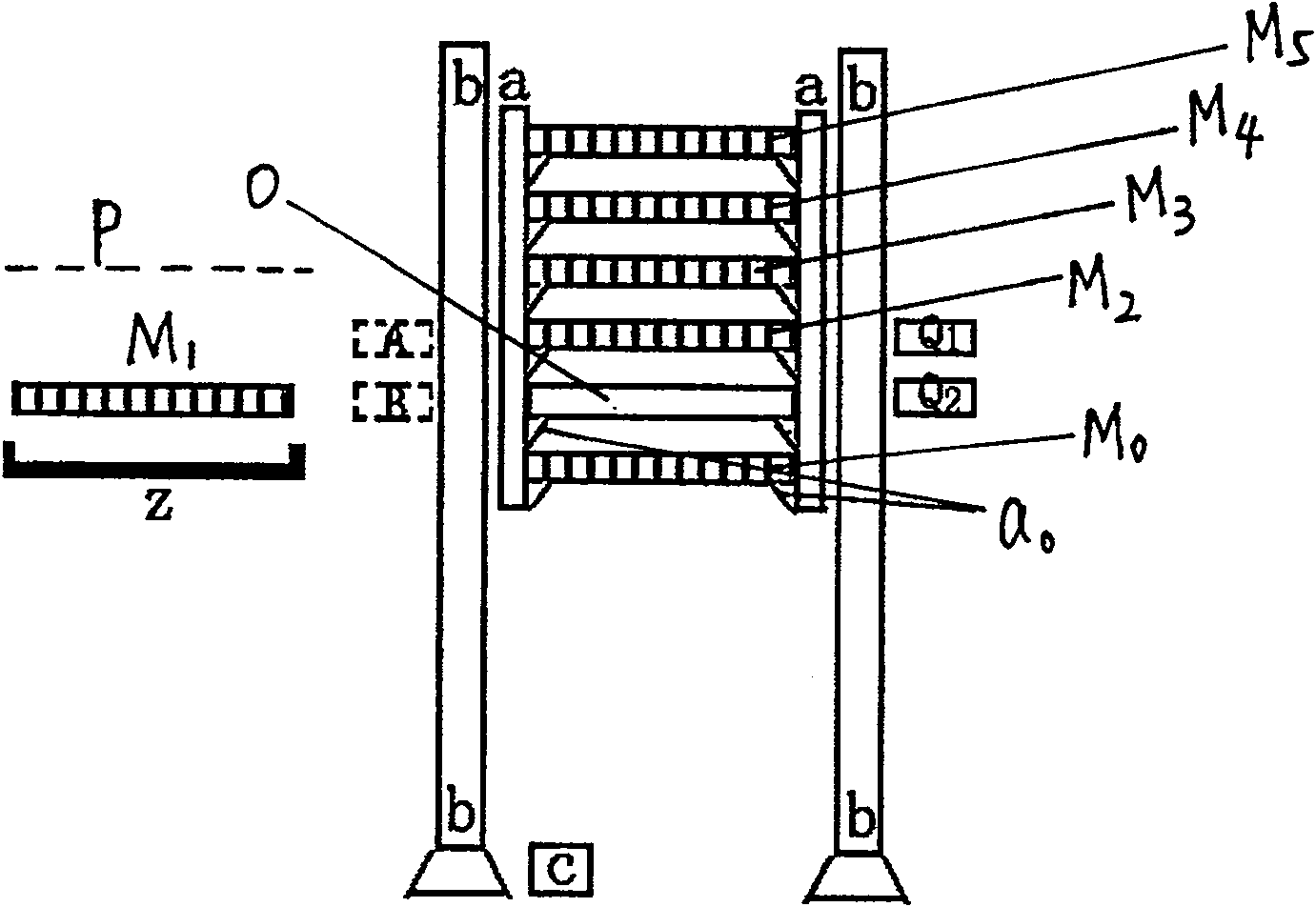

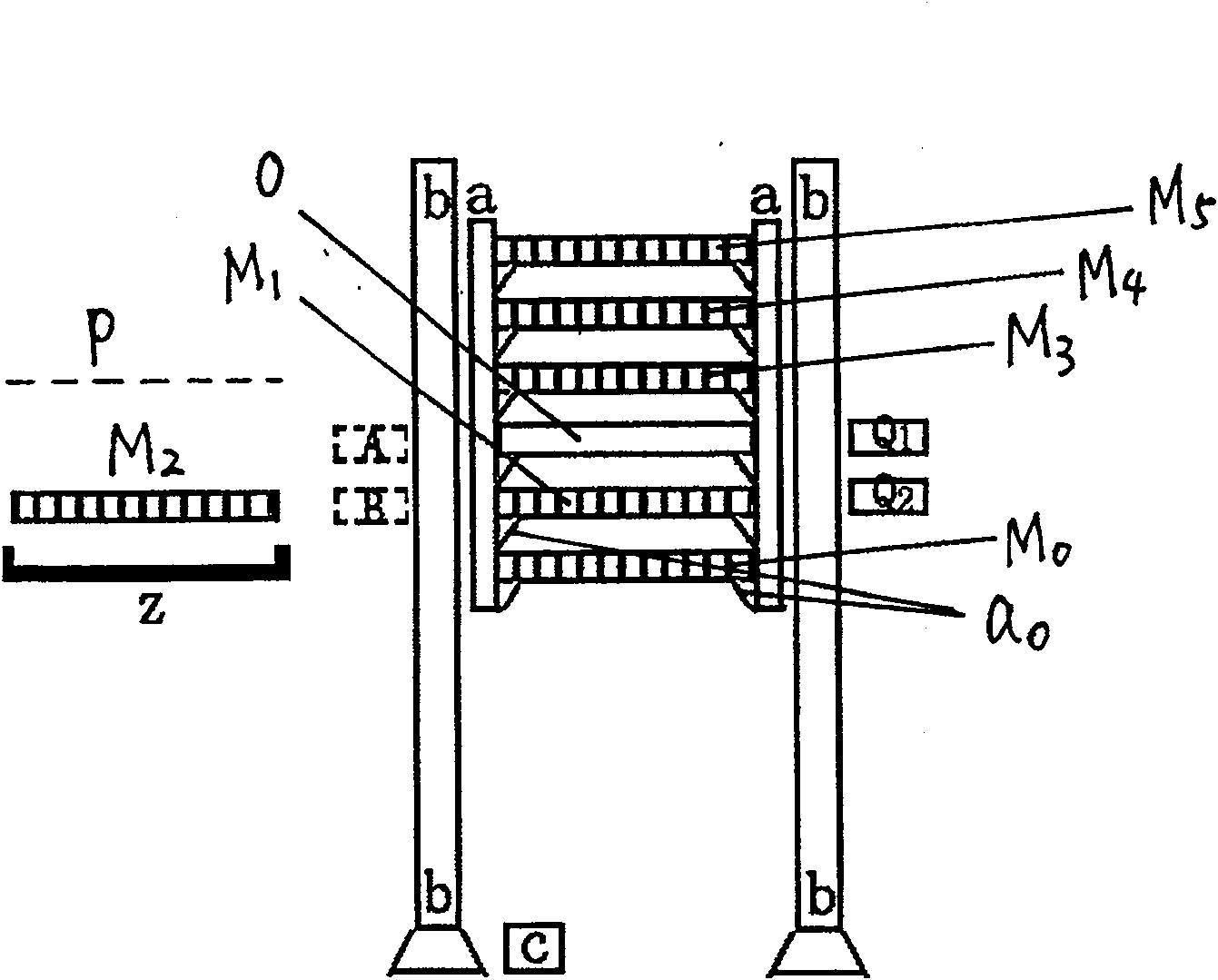

[0127] 2), prepare two sets of hole pattern planar templates consisting of 2 different hole pattern shapes, such as figure 2 Hole pattern template vertical circulation system and associated equipment elements shown and taken as Image 6 The position shown is installed, and the 2 flat hole pattern templates with different hole pattern shapes in the first set of vertical circulation system are labeled M 1 and M 2 Indicates that in the second set of vertical circulation system, two different hole pattern plane templates with different hole pattern shapes are labeled N 1 and N 2 express. Among them, each equipment element includes the label a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com