Quaterfoil polyester fiber or filament yarn having antimicrobial and moisture absorption sweat discharging functions

A polyester fiber and quatrefoil technology, applied in the field of fibers or filaments, can solve the problems of poor bending resistance, poor bending resistance of fibers, and cross-section abnormalization, etc., to achieve good moisture absorption and quick drying performance, Ease of wearing and deodorizing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

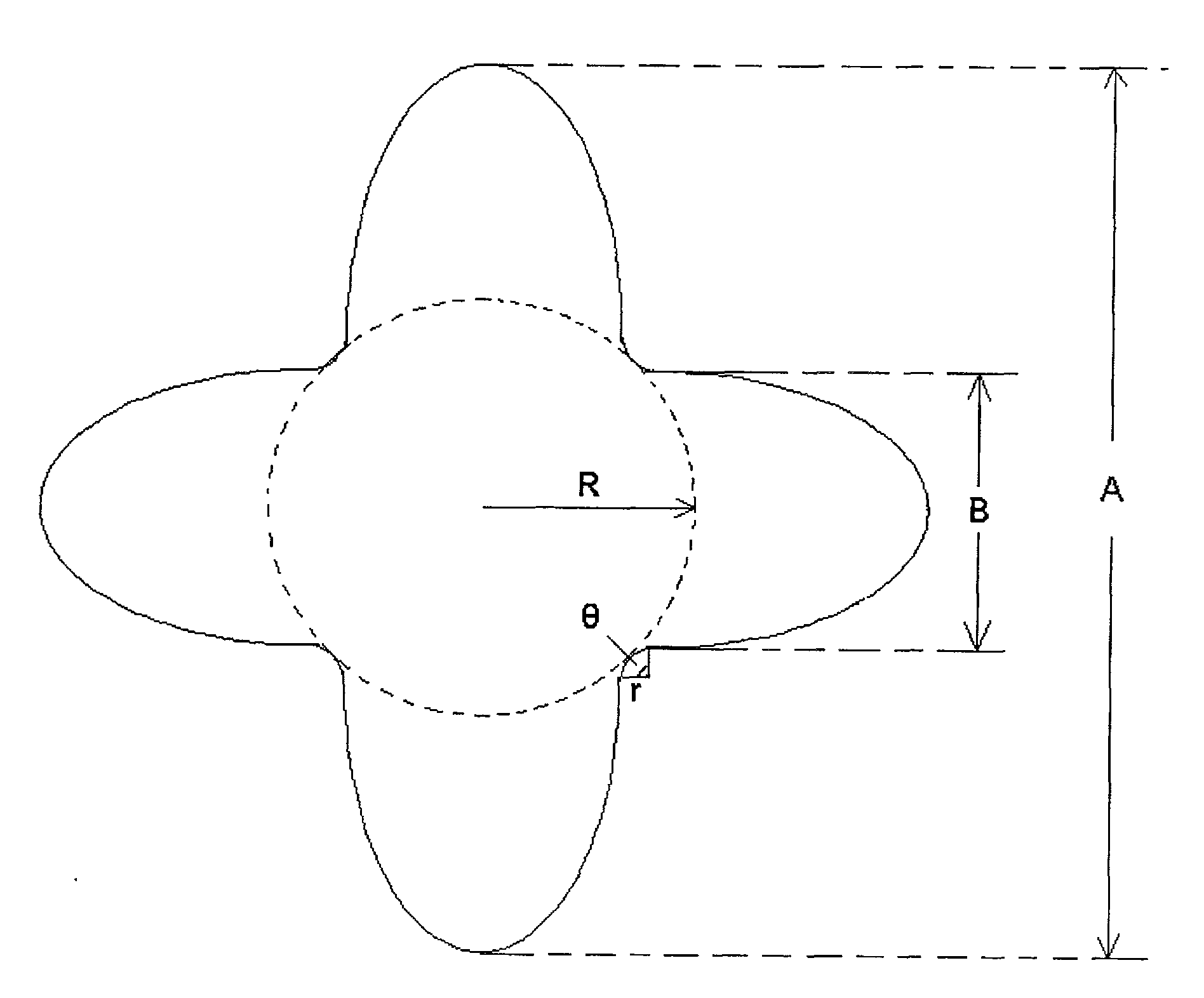

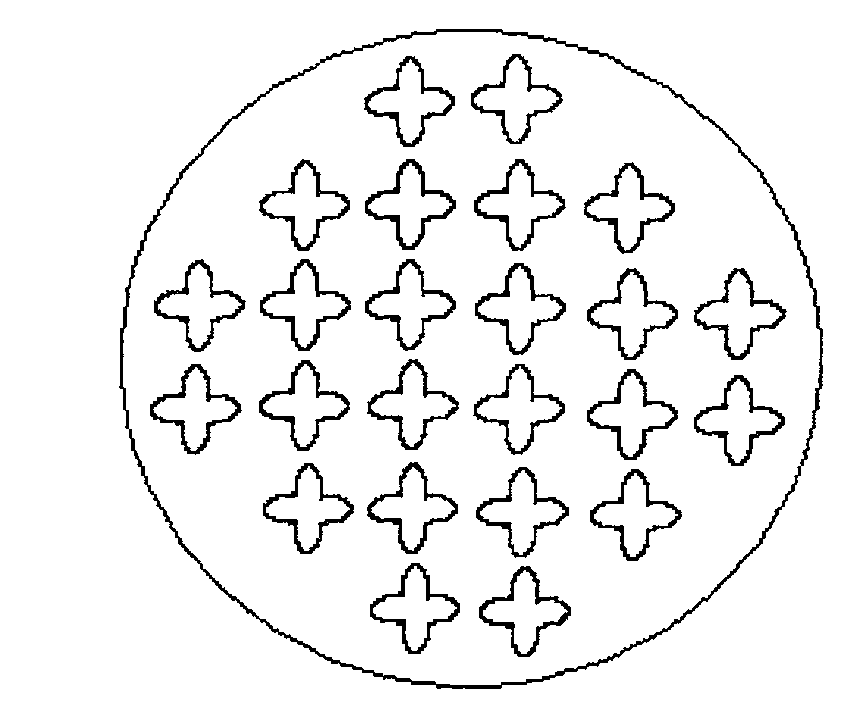

[0054] Weigh 0.3 kg of zirconium phosphate-coated silver powder with a particle size of 30nm and an appropriate amount of carrier zeolite to prepare antibacterial powder according to methods commonly used in the art; weigh 1.2 kg of 2G-T polymer of LRV23.5 and the obtained The antibacterial powder blending is prepared into antibacterial polyester masterbatch; After the 2G-T polymer melting of antibacterial polyester masterbatch and 28.5 kilograms of LRV23.5 adopts the spinneret with the spinneret hole of cross-section shape of the present invention The plate extruded fibers at approximately 70 pph per minute and the spinning speed was 2900 ypm. The cross-section of the spinneret holes on the spinneret is elliptical blades with 4 flounces, the 4 elliptical blades are the same size and vertically symmetrical; the width B of the elliptical blades is the same as the distance between the two symmetrical The ratio of distance A is 1:3.

[0055] The above method obtains a four-lobed...

Embodiment 2

[0057] Weigh 1 kg of silver nitrate powder with a particle size of 100nm and an appropriate amount of carrier zeolite to prepare an antibacterial powder according to a method commonly used in the art; weigh 4 kg of 2G-T polymer of LRV23.5 and the resulting antibacterial powder Mix and prepare antibacterial polyester master batch; Adopt the spinneret with the spinneret hole of cross-sectional shape of the present invention after the 2G-T polymkeric substance melting of antibacterial polyester master batch and 45 kilograms LRV23. The fiber was extruded at 70pph and the spinning speed was 2900ypm. The cross-section of the spinneret holes on the spinneret is elliptical blades with 4 flounces, the 4 elliptical blades are the same size and vertically symmetrical; the width B of the elliptical blades is the same as the distance between the two symmetrical The ratio of the distance A is 1:10; there are fan-shaped concave arcs between the four elliptical blades, and the central angle θ...

Embodiment 3

[0059] Weigh 0.6 kg of silver oxide powder with a particle size of 60nm and an appropriate amount of carrier zeolite to prepare an antibacterial powder according to a method commonly used in the art; weigh 2.4 kg of 3G-T polymer and blend it with the resulting antibacterial powder to prepare an antibacterial powder Polyester masterbatch; after melting antibacterial polyester masterbatch with 197 kg of 3G-T polymer, it is used Figure 4 The spinneret of the illustrated spinneret hole extruded fibers at a rate of approximately 70 pph per minute, with a spinning speed of 2900 ypm. The cross-section of the spinneret holes on the spinneret is elliptical blades with 4 flounces, the 4 elliptical blades are the same size and vertically symmetrical; the width B of the elliptical blades is the same as the distance between the two symmetrical The ratio of the distance A is 1:3; there is a fan-shaped concave arc between the four elliptical blades, and the central angle θ corresponding to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com