Terminal conveyor

A technology of conveying devices and terminals, which is applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., and can solve the problem that terminals cannot enter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

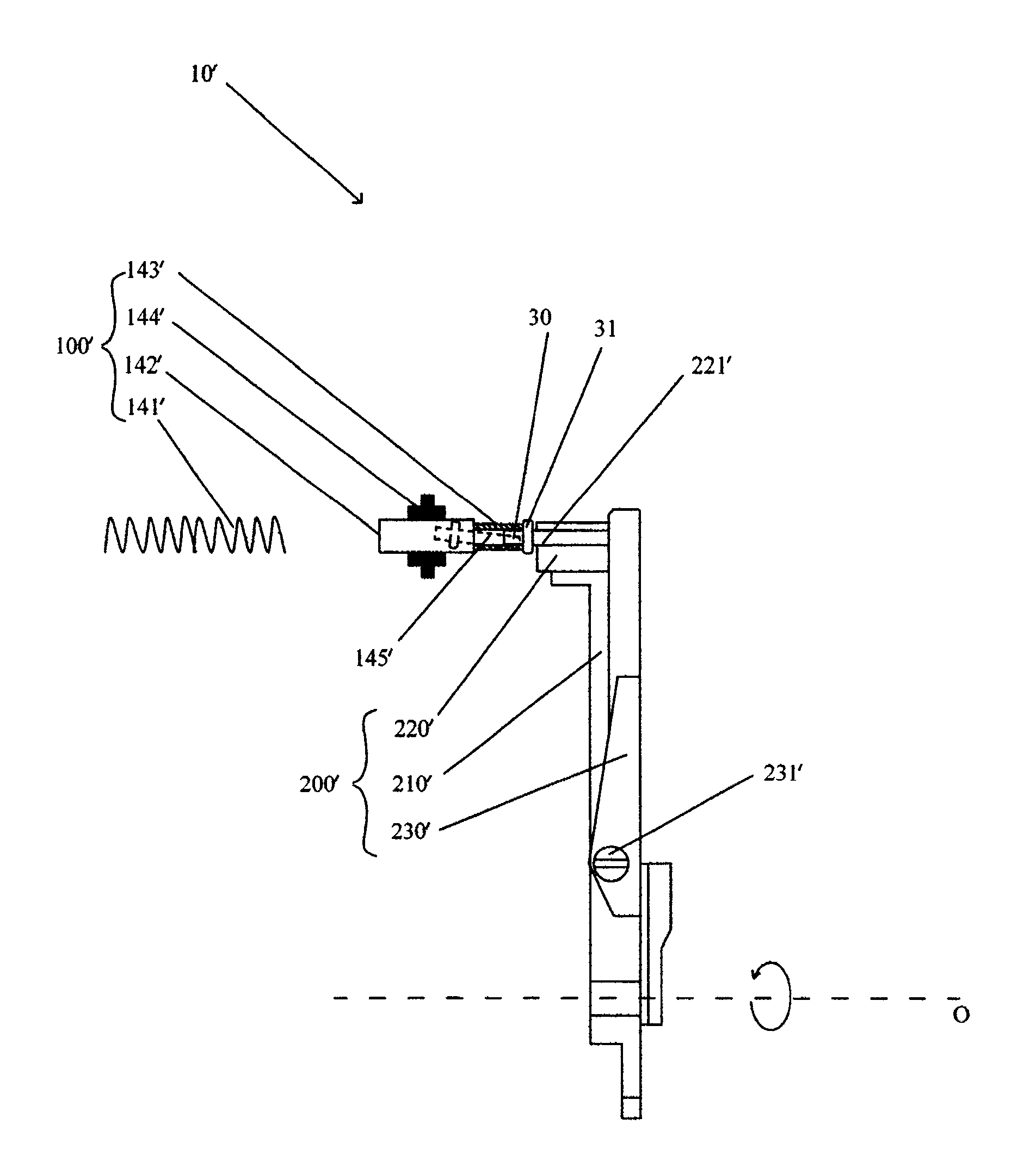

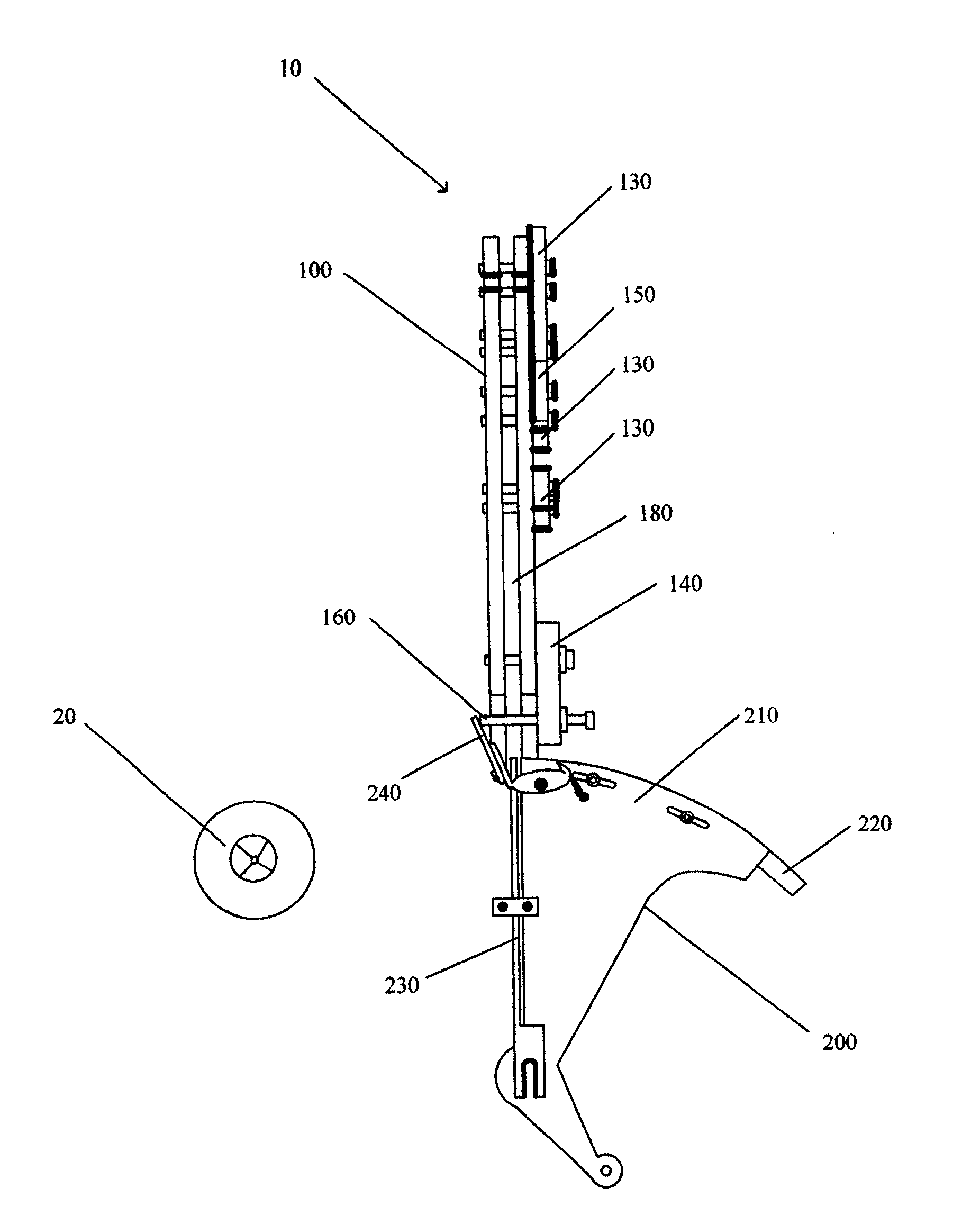

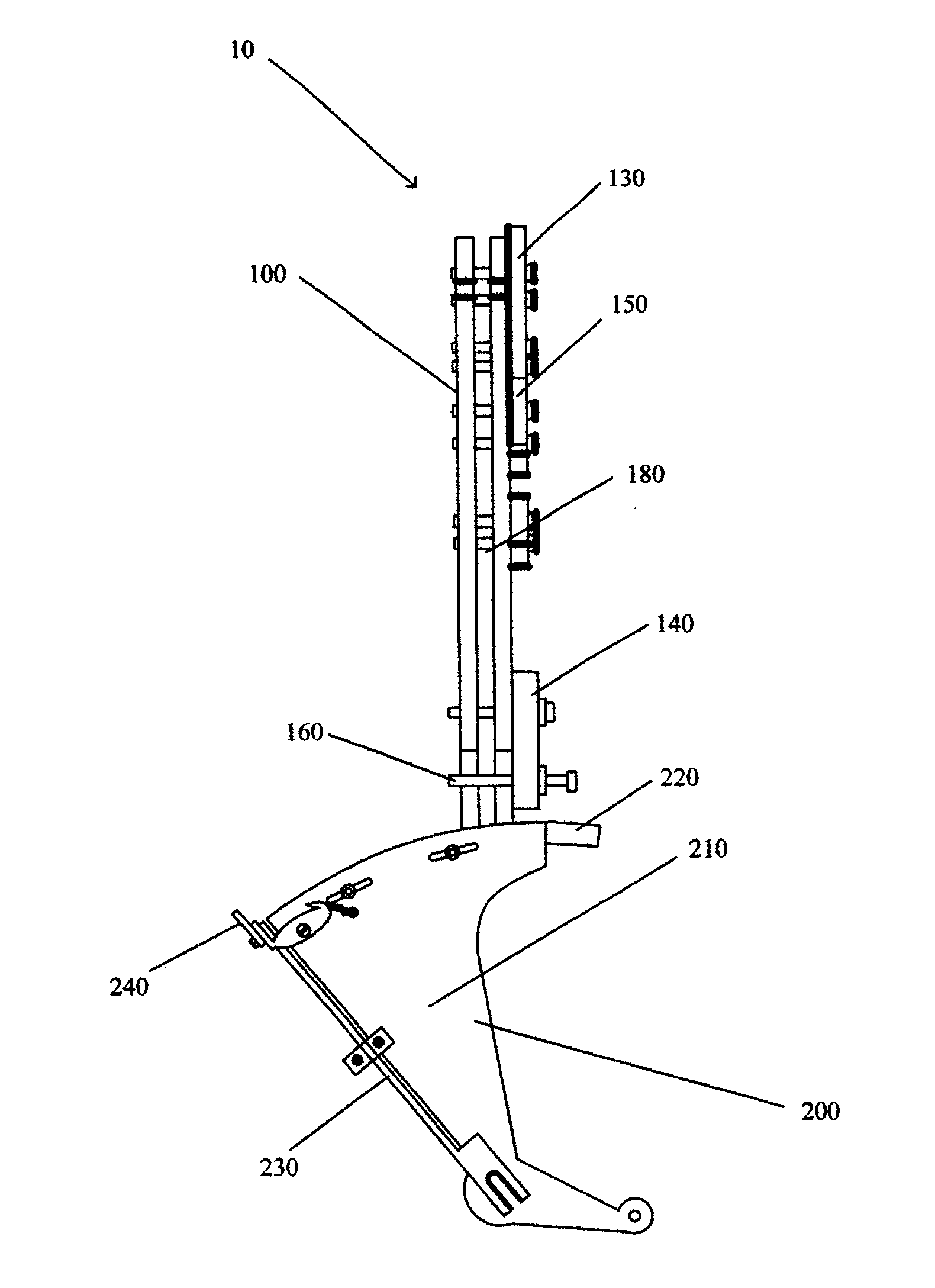

[0036] see figure 2 , image 3 and Figure 4 , The terminal conveying device 10 of the present invention includes a terminal sorting roller (not shown in the figure), a guiding mechanism 100 and a conveying mechanism 200 . The transmission mechanism 200 is slidably supported under the guide mechanism 100, and the transmission mechanism 200 can rotate around a rotation axis o (such as Figure 13 and Figure 14 shown) to rotate. The terminal 30 discharged from the terminal sorting roller slides along the guide mechanism 100 to the bottom end of the guide mechanism 100 and enters the transfer mechanism 200; then, the transfer mechanism 200 rotates around the rotation axis o to the position of a rotating clamp 20 and pushes the terminal 30 into The jig 20 is rotated for processing.

[0037] Please also refer to Figure 4 to Figure 7 , the guiding mechanism 100 has a first guiding rail 110 , a second guiding rail 120 , a plurality of adjusting plates 130 , a first fixing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com