one way exhaust valve

A one-way exhaust valve and exhaust hole technology, applied in the direction of control valve, valve device, functional valve type, etc., can solve problems such as broken bags, and achieve the effect of reducing broken bags and reducing shock waves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with the best embodiment.

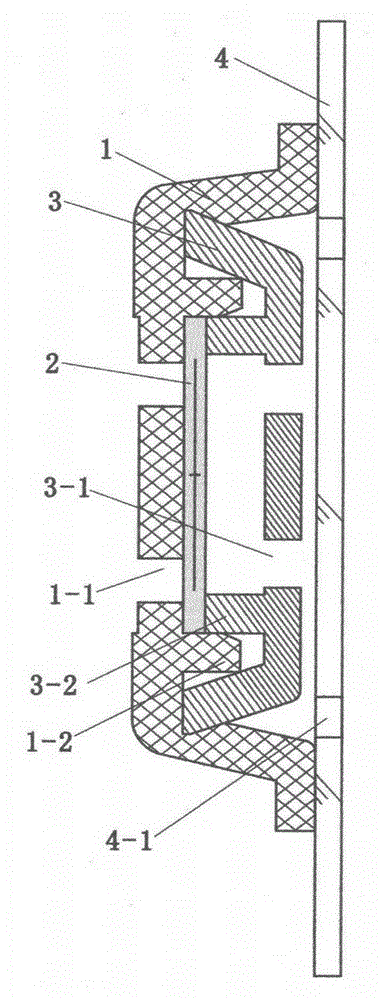

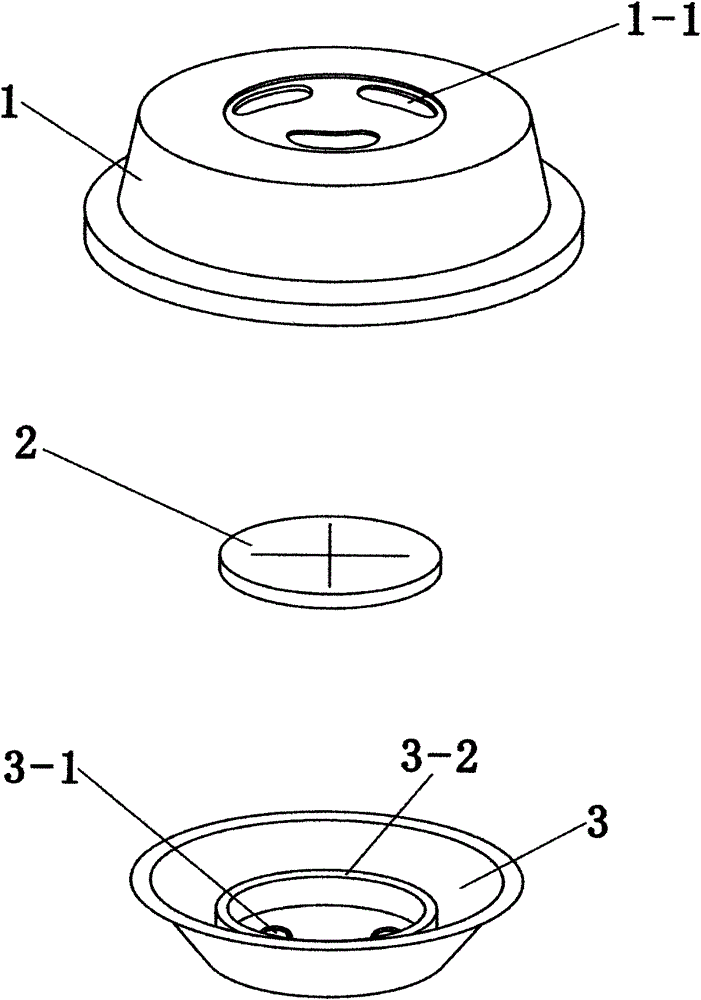

[0017] Such as Figure 1-2 As shown, the one-way exhaust valve includes a packaging bag with a packaging bag exhaust hole 4-1 on the inner wall 4 of the packaging bag, and also includes a one-way exhaust valve composed of a valve seat 1, a self-sealing valve piece 2 and a valve cover 3. valve;

[0018] The valve seat 1 is a hat-shaped structure, the bottom of the valve seat 1 has a valve seat air intake hole 1-1, and the center of the bottom has a positioning ring 1-2, and the valve seat 1 is covered on the inner wall 4 of the packaging bag, and there is a packaging bag exhaust The position of the hole 4-1, the edge of the valve seat 1 is connected with the inner wall 4 of the packaging bag;

[0019] The valve cover 3 is a flat-bottomed bowl-shaped structure with a diameter smaller than the valve seat 1. The bottom of the bowl of the valve cover 3 has a valve cover exhaust hole 3-1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com